cbui2

Member

i just found this thread so i am sharing my new project.

Here it goes, beginning of the year I had set out a new year resolution to setup a full blown reef system w/self automated capabilities as possible, also stated in the title, this is my very first full reef system tank ever.. I guess you can call me a 31 yrs. old virgin for reefkeeping, but not in real life LOL. Just a few months of knowledge, and countless hours through the night-morning reading and going through plenty #'s of threads also sending emails to all the guys here and getting back the quickest response ever in no time, and I can't thank you enough to everyone here on -- that is so helpful, unlike LFS here in New Orleans who just want to collect money, but get very little if any info. Please let me know at anytime if I am doing anything wrong or any helpful advice will be appreciated, Thanks.

Here are the list of equipment I have acquire,

Tank:

96"L x 48"W x 30"H (1" Cell Cast Acrylic w/1" Eurobace, 3/4" Bottom)

Custom built by The Aquarium Company in Winthrop, MN (Franz Metzger)

Stand:

48"H w/2" x 2" Custom built steel stand w/Line-X treatment

Custom built by The Aquarium Company in Winthrop, MN (Franz Metzger)

1st Refugium 150gal:

48"L x 30"W x 24"H (1/2" Acrylic)

2nd Refugium 135gal:

72"L x 18"W x 24"H (1/2" Glass)

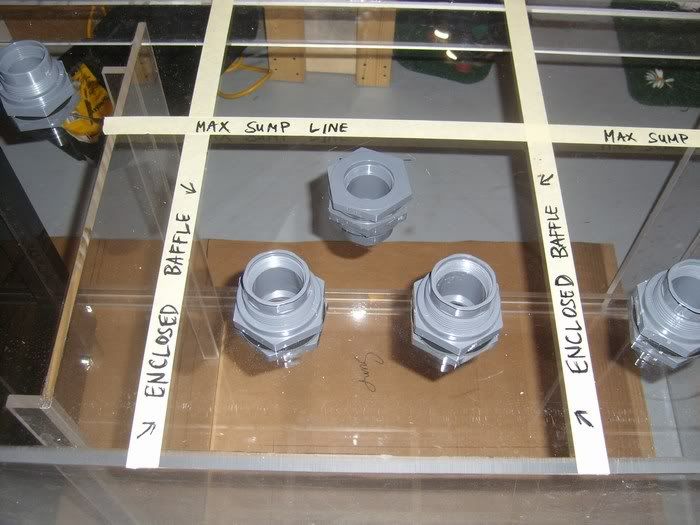

Main Sump 150gal:

48"L x 30"W x 24"H (1/2" Acrylic)

Water Change Sump 180gal:

72"L x 18"W x 31"H 1/2" Glass)

Frag 100gal:

72"L x 18"W x 17"H (1/2" Glass)

Pumps:

4 Sequence 1000 SEQ4300

sump returns, skimmers, chiller, and reactors

Closed Loop:

2 Sequence 1000 SEQ5800

2 4-Way V3 Oceans Motion

Protein Skimmer:

Deltec AP1004

Calcium Reactor:

Deltec PF1001 w/ROWALith C+ Media

Phosphate Reactors:

Deltec FR1016 w/ROWAPhos® Media

Kalkwasser Stirrers:

Deltec KM500S w/ROWAKalk Media

Chiller:

Tradewind IL-180-S 1.5HP 18,000BTU

Heater:

?

Dosing pump:

SpectraPure Litermeter 3

RO-DI unit:

SpectraPure MaxCap 5 stage produces 180 gal/day

Lights:

6 Single 400w PFO HQI Metal Halide Ballast

3 Lumenarc III Pendenat Reflectors

3 Reef Optix V Super Sun Reflectors

2 IceCap 660 VHO Ballast 8 36" URI Super

9 PFO Flat Night Light Moonlights

Controller:

Neptune AquaController 3 Pro

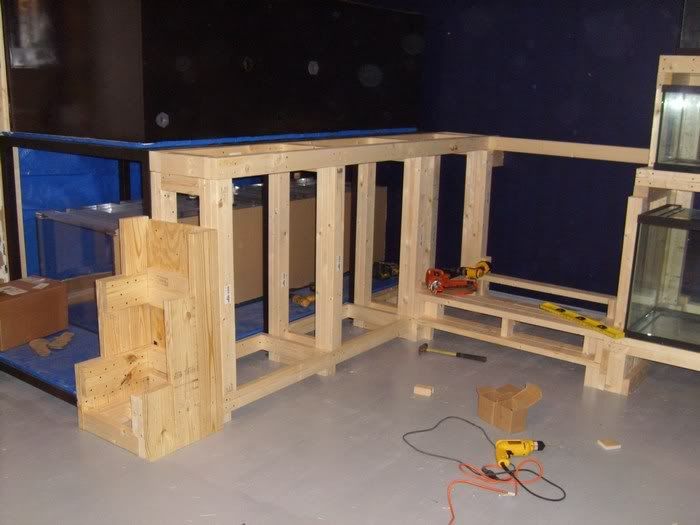

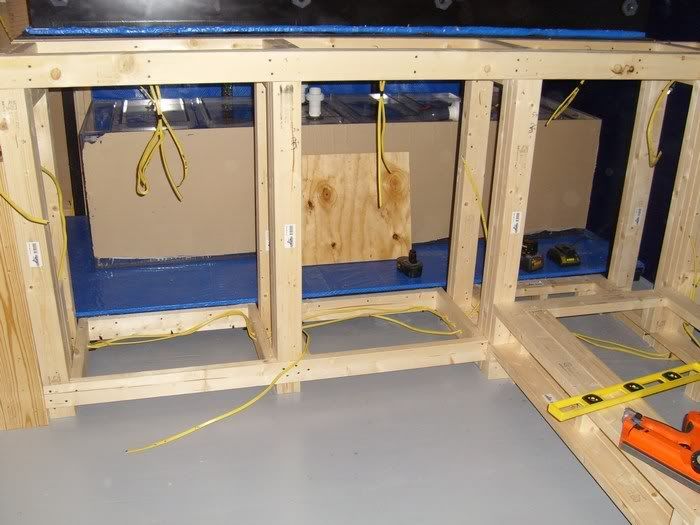

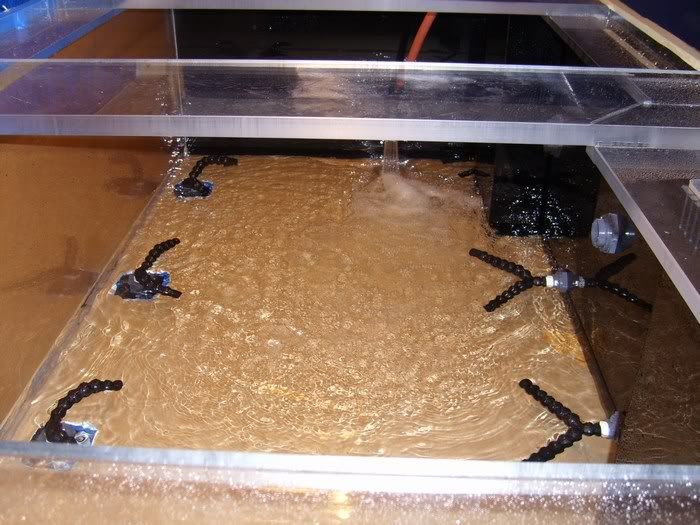

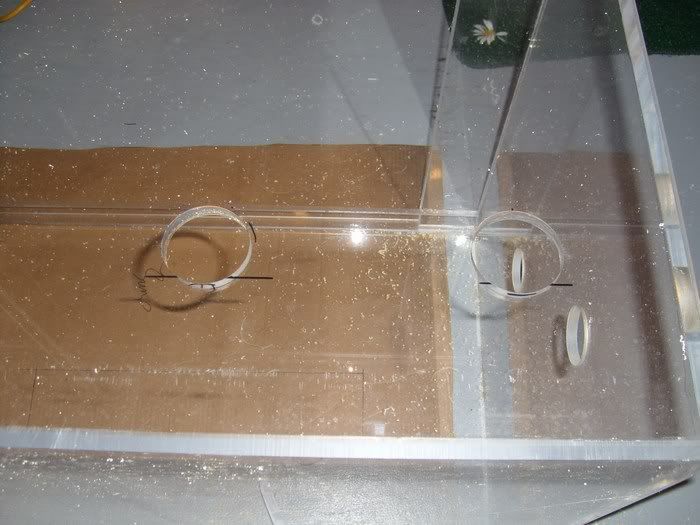

here are some pics, project have been started since 3-10-07

Here it goes, beginning of the year I had set out a new year resolution to setup a full blown reef system w/self automated capabilities as possible, also stated in the title, this is my very first full reef system tank ever.. I guess you can call me a 31 yrs. old virgin for reefkeeping, but not in real life LOL. Just a few months of knowledge, and countless hours through the night-morning reading and going through plenty #'s of threads also sending emails to all the guys here and getting back the quickest response ever in no time, and I can't thank you enough to everyone here on -- that is so helpful, unlike LFS here in New Orleans who just want to collect money, but get very little if any info. Please let me know at anytime if I am doing anything wrong or any helpful advice will be appreciated, Thanks.

Here are the list of equipment I have acquire,

Tank:

96"L x 48"W x 30"H (1" Cell Cast Acrylic w/1" Eurobace, 3/4" Bottom)

Custom built by The Aquarium Company in Winthrop, MN (Franz Metzger)

Stand:

48"H w/2" x 2" Custom built steel stand w/Line-X treatment

Custom built by The Aquarium Company in Winthrop, MN (Franz Metzger)

1st Refugium 150gal:

48"L x 30"W x 24"H (1/2" Acrylic)

2nd Refugium 135gal:

72"L x 18"W x 24"H (1/2" Glass)

Main Sump 150gal:

48"L x 30"W x 24"H (1/2" Acrylic)

Water Change Sump 180gal:

72"L x 18"W x 31"H 1/2" Glass)

Frag 100gal:

72"L x 18"W x 17"H (1/2" Glass)

Pumps:

4 Sequence 1000 SEQ4300

sump returns, skimmers, chiller, and reactors

Closed Loop:

2 Sequence 1000 SEQ5800

2 4-Way V3 Oceans Motion

Protein Skimmer:

Deltec AP1004

Calcium Reactor:

Deltec PF1001 w/ROWALith C+ Media

Phosphate Reactors:

Deltec FR1016 w/ROWAPhos® Media

Kalkwasser Stirrers:

Deltec KM500S w/ROWAKalk Media

Chiller:

Tradewind IL-180-S 1.5HP 18,000BTU

Heater:

?

Dosing pump:

SpectraPure Litermeter 3

RO-DI unit:

SpectraPure MaxCap 5 stage produces 180 gal/day

Lights:

6 Single 400w PFO HQI Metal Halide Ballast

3 Lumenarc III Pendenat Reflectors

3 Reef Optix V Super Sun Reflectors

2 IceCap 660 VHO Ballast 8 36" URI Super

9 PFO Flat Night Light Moonlights

Controller:

Neptune AquaController 3 Pro

here are some pics, project have been started since 3-10-07