aquaknight

Active Member

Earlier last week, the left brace on my 240gal let go. I walked out to the tank and found the corner of the halide fixture in the water, and the front pane deflected over 2". How it didn't fail, I have no idea. I immediately drained the tank about half way (having extra rubbermaids on hand saved my bacon). The tank has since been stabilized. I've added the skimmer from the sump directly into the tank, and doing daily WC's. Not a ton of room, but with only 5 fish (granted some are large) in a half-filled 240, they should be fine.

My concern here is why the tank broke. I did buy the tank used. The story from the guy was that during one of his moves, the moving company accidentally rolled the tank onto something and broke both braces. The moving companies insurance paid for a new larger tank, and picking my tank up from him, he sure did have a larger tank setup, and he seemed generally like a good guy.

I ordered the braces from a local company, 3/8" thick and 15" wide. There are also two 3"-4" braces on the sides of the tank that were there, that I did not touch. I used GE/Momentive RTV103 on the new braces. The silicone that comes highly recommended via another message board. The tank was running for 4 months, then I moved a bit under 3 months ago. Moving a 250lb tank and a 350lb stand wasn't the easiest thing in the world, but I believe we didn't put any more undesired stress on the tank, then one would normally see during a move.

The issues that could have caused it.

The stand. We built the stand ourselves over the course of a few months. Like to think we did a good job. Checked and everything seemed good, we used a long piece of square aluminum tubing to verify, and the stand was generally flat. Could see some light shining through, but nothing what I would think is out of spec.

The level. The tank didn't sit exactly level. Over the 24" gap, the back sits 1.35mm lower then the front. Again, not ideal, but I think that's in spec?

The tank is itself. Maybe the guy did lie? It was a previously busted tank I patched back together. Although, it wouldn't think it would have lasted at all this way. Or maybe the move twisted the tank?

The braces. Is 36" of support, 30" of real support, not enough for a 8' foot tank?

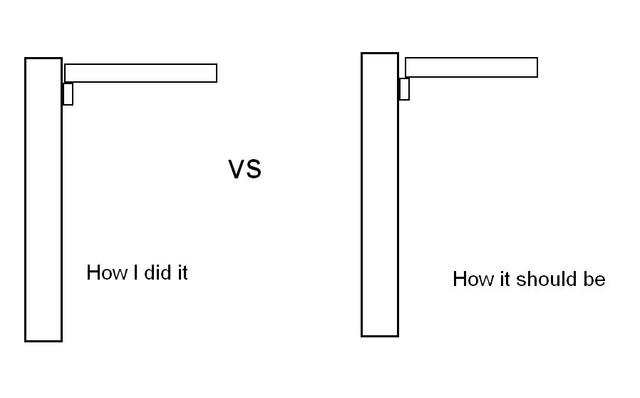

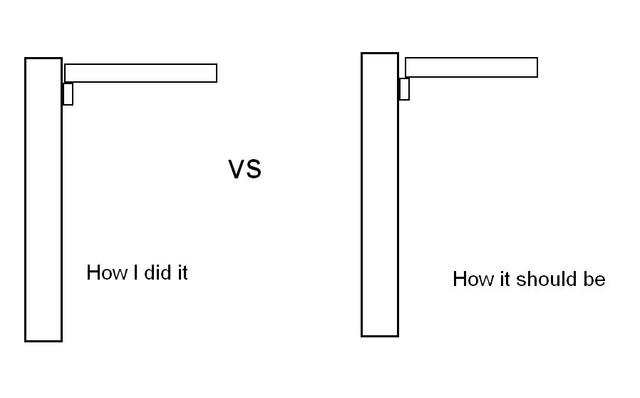

My brace job. Not to influence anyone's own decision, but this I want I keep coming back too. I forget the exactly numbers, but for now lets just roll with it. I ordered the braces 23 5/8th long. When I picked that up, got home and measured, they were more like 23 15/16th. They just squeezed in, but won't slide into their correct positions in the tank. So we took a flap sanding disc on the angle-grinder to them to shorten them up. We marked the glass and made sure were still square. However even after that, they were still 'a little tight.' The braces sit on top of a small nub of glass. Here's a diagram of why I think it was this.

My theory is that I just didn't get enough silicone inbetween the two panes. That's there the strength from a perpendicular joint of two glass panes comes from. I only got silicone on the top of the brace, and on the under side. Anyone else agree?

My concern here is why the tank broke. I did buy the tank used. The story from the guy was that during one of his moves, the moving company accidentally rolled the tank onto something and broke both braces. The moving companies insurance paid for a new larger tank, and picking my tank up from him, he sure did have a larger tank setup, and he seemed generally like a good guy.

I ordered the braces from a local company, 3/8" thick and 15" wide. There are also two 3"-4" braces on the sides of the tank that were there, that I did not touch. I used GE/Momentive RTV103 on the new braces. The silicone that comes highly recommended via another message board. The tank was running for 4 months, then I moved a bit under 3 months ago. Moving a 250lb tank and a 350lb stand wasn't the easiest thing in the world, but I believe we didn't put any more undesired stress on the tank, then one would normally see during a move.

The issues that could have caused it.

The stand. We built the stand ourselves over the course of a few months. Like to think we did a good job. Checked and everything seemed good, we used a long piece of square aluminum tubing to verify, and the stand was generally flat. Could see some light shining through, but nothing what I would think is out of spec.

The level. The tank didn't sit exactly level. Over the 24" gap, the back sits 1.35mm lower then the front. Again, not ideal, but I think that's in spec?

The tank is itself. Maybe the guy did lie? It was a previously busted tank I patched back together. Although, it wouldn't think it would have lasted at all this way. Or maybe the move twisted the tank?

The braces. Is 36" of support, 30" of real support, not enough for a 8' foot tank?

My brace job. Not to influence anyone's own decision, but this I want I keep coming back too. I forget the exactly numbers, but for now lets just roll with it. I ordered the braces 23 5/8th long. When I picked that up, got home and measured, they were more like 23 15/16th. They just squeezed in, but won't slide into their correct positions in the tank. So we took a flap sanding disc on the angle-grinder to them to shorten them up. We marked the glass and made sure were still square. However even after that, they were still 'a little tight.' The braces sit on top of a small nub of glass. Here's a diagram of why I think it was this.

My theory is that I just didn't get enough silicone inbetween the two panes. That's there the strength from a perpendicular joint of two glass panes comes from. I only got silicone on the top of the brace, and on the under side. Anyone else agree?