2quills

Well-Known Member

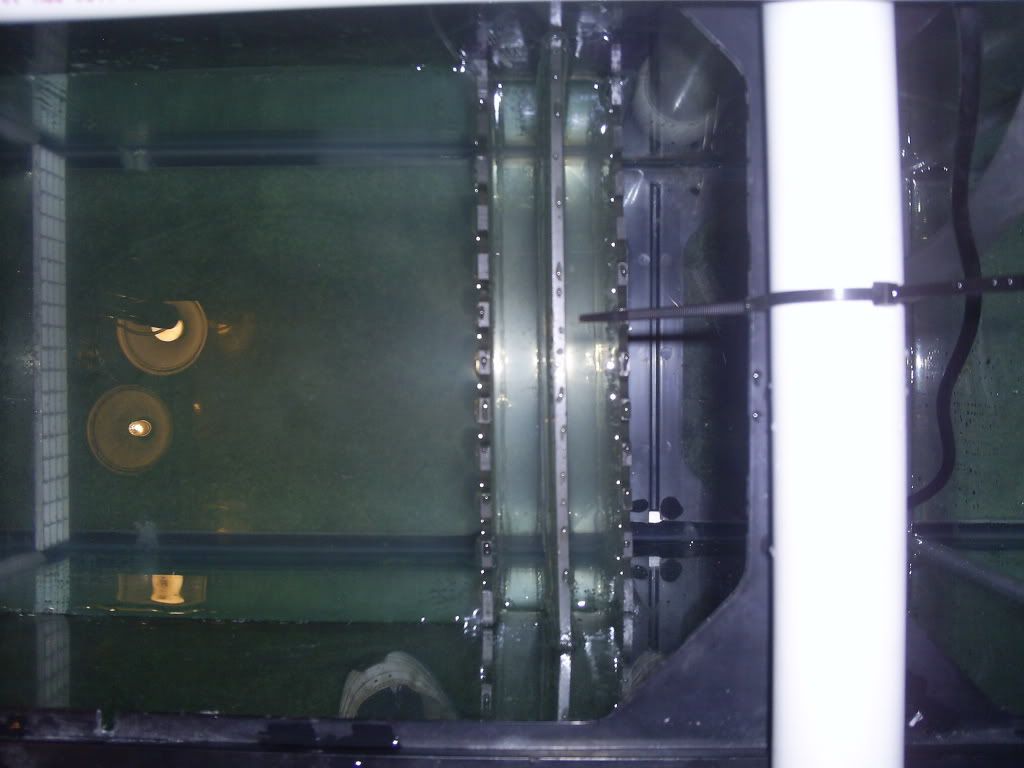

Well I decided to start working on the sump for my 125G DT today. The sump is a 55G tank that I picked up from a friend of mine for $0 dollars

. Went out to HD and stopped by the LFS to pick up the supplies. I know it isn't the prettiest thing in the world but it's my first one. It's still not done, I need to finish making the supports for the media racks. And hindsight is 20/20 but I'm contemplating taking the baffle out of the fuge section and making it a little bit taller. All in all though I think it's turning out OK.

. Went out to HD and stopped by the LFS to pick up the supplies. I know it isn't the prettiest thing in the world but it's my first one. It's still not done, I need to finish making the supports for the media racks. And hindsight is 20/20 but I'm contemplating taking the baffle out of the fuge section and making it a little bit taller. All in all though I think it's turning out OK.

I haven't seen many that were done this way but I wanted to go with a 4 chamber system in order to run some various media if I ever wanted to. From left to right the system works like this...

1. Drain from the tank comes into first chamber where 2 different types of media could be used.

2. Protien skimmer chamber

3. Return chamber

4. Refugium.

DT will be drilled for 2 1-1/2" bulkheads, each having their own 700gph overflow box for 1400gph draining capability. One of the drains will be split with a seperate feed for the fuge to be supplied with dirty water.

Still unsure which pump I want to go with for my return. I'm thinking about either the Mag12 (1200gph) wich will give me approximately 1100gph with 5 feet of head, or the Ehiem 1262 (900gph) which will give me about 700gph. I would rather have an Ehiem but I don't know if it's going to give me enough flow for my 125G DT. Anybody have any thoughts on this???

Thanks in advance.

I haven't seen many that were done this way but I wanted to go with a 4 chamber system in order to run some various media if I ever wanted to. From left to right the system works like this...

1. Drain from the tank comes into first chamber where 2 different types of media could be used.

2. Protien skimmer chamber

3. Return chamber

4. Refugium.

DT will be drilled for 2 1-1/2" bulkheads, each having their own 700gph overflow box for 1400gph draining capability. One of the drains will be split with a seperate feed for the fuge to be supplied with dirty water.

Still unsure which pump I want to go with for my return. I'm thinking about either the Mag12 (1200gph) wich will give me approximately 1100gph with 5 feet of head, or the Ehiem 1262 (900gph) which will give me about 700gph. I would rather have an Ehiem but I don't know if it's going to give me enough flow for my 125G DT. Anybody have any thoughts on this???

Thanks in advance.