richamc01

Member

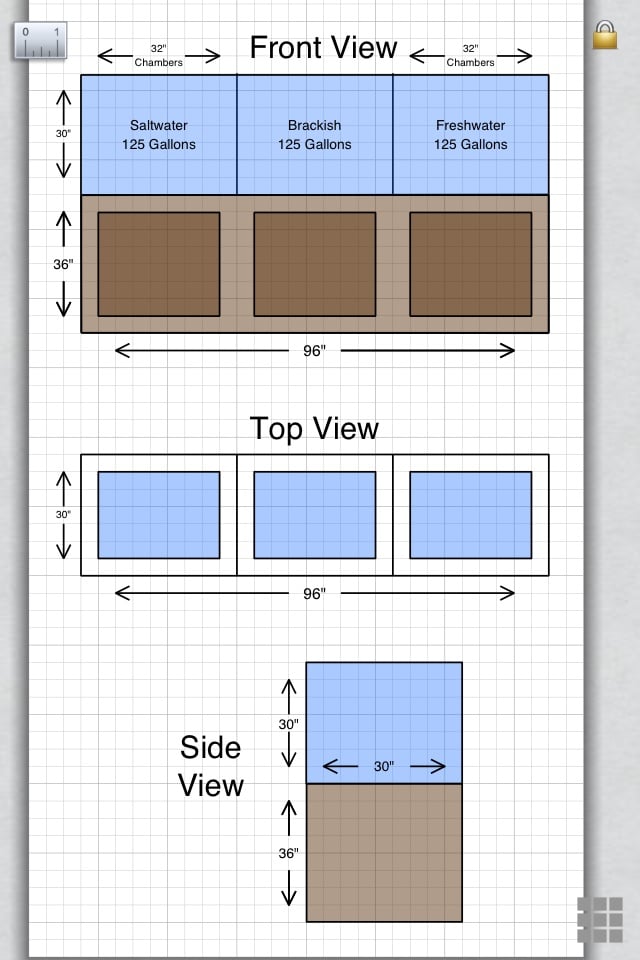

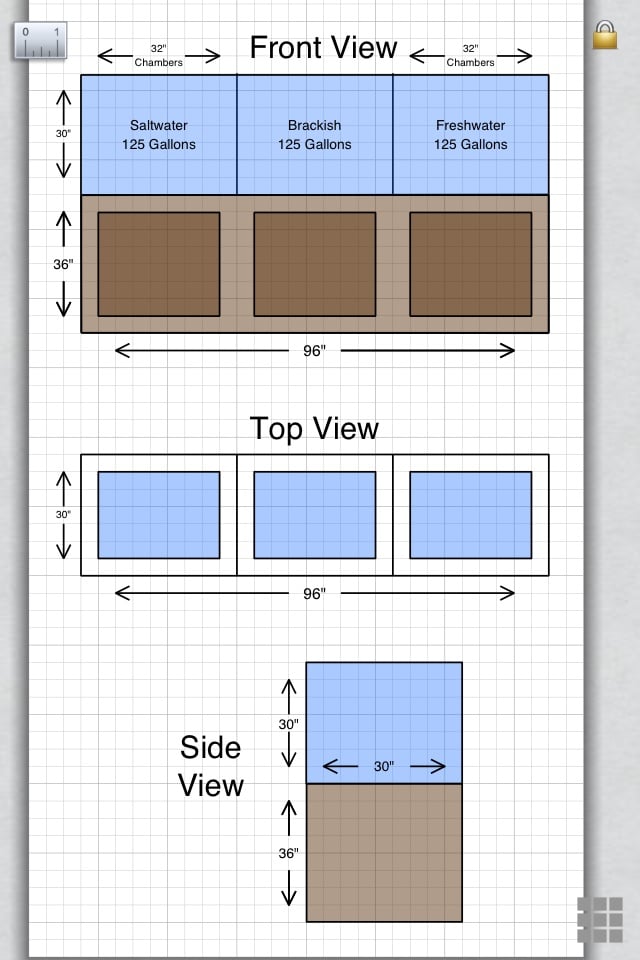

I want to build a 375 gallon tank in the future and I'm looking at acrylic prices now. The demensions of the tank will be: 96x30x30 (LXWXH). The tank will be separated into three separate "chambers". Saltwater, brackish, freshwater. The dividers will be at 32". Making the "chamber" 32x30x30. I'm curious as to what thickness the acrylic will need to be. I know that anything over 24" tall should be 3/4" thick but since I have the dividers, they should provide some bracing right? I also plan to do some bracing around the top as well but I'm hoping to use 1/2" or even 3/8" to save some $$$$.

Thoughts?

Thoughts?