islandkoa

Member

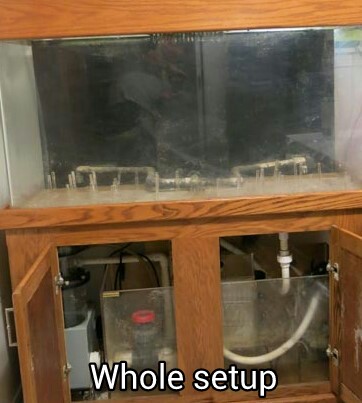

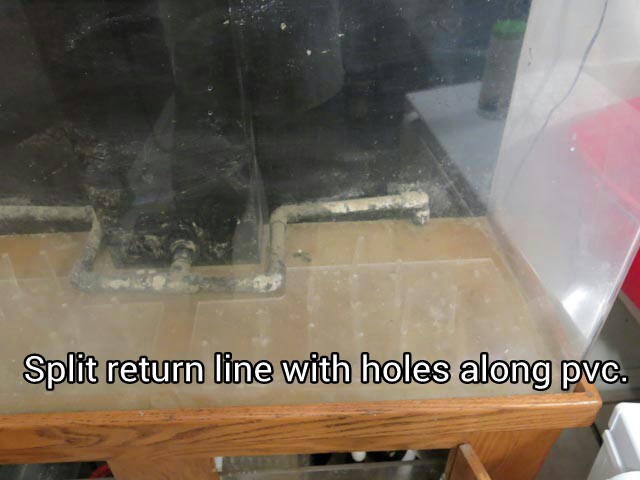

I recently purchased a pre-plumbed 90 gallon acrylic tank (with sump/stand) from someone. I noticed that the return line went up through the bottom, back (in the back plumbing housing area). The return pipe goes up near the graded overflow, does a 180 degree turn, goes back down, then goes out of the housing about 2" from the bottom where it is split. Each split runs along the back and has multiple holes pointed forward and up along the PVC. It also has two holes near the highest point below the 90 degree elbow at the top (to break the vacuum if loss of power) that ineffectively sends some return flow back down the drain to the sump. This coupled with the added plumbing length and multiple 90 degree elbows currently required to reach the top then bottom of the tank, seem like an unnecessary attenuation of the return flow.

I think that I should modify the return plumbing to have it exit near the water surface (like most others). Maybe for curiousity fulfillment, I'll measure the flow rate with this current set up (I have to clean the tank anyway) and compare it to the rate after the modification. Another option is to just leave it alone, trust the system won't overflow in the event of a power loss and live with the attenuated return turnover.

Any thoughts on this before I flip a coin?

I think that I should modify the return plumbing to have it exit near the water surface (like most others). Maybe for curiousity fulfillment, I'll measure the flow rate with this current set up (I have to clean the tank anyway) and compare it to the rate after the modification. Another option is to just leave it alone, trust the system won't overflow in the event of a power loss and live with the attenuated return turnover.

Any thoughts on this before I flip a coin?