yannifish

Active Member

Hello, everyone, it has been ages since I've been on here.

I have a 55 gallon tank, and am planning on breaking it down due to multiple issues (algae mainly) and want to set it up again the proper way (using RO/DI water...).

I am currently using a HOB overflow that uses an aqualifter pump to pull air out of the U-tube. Today that pump decided to quit, and luckily I noticed the high water levels before overflow slowed down enough that the tank overflowed. For the night I manually sucked the air out of the U-tube, I'll look into replacing the pump tomorrow. (and set up the ten gallon tank my two clownfish will live in until the 55 is set up again).

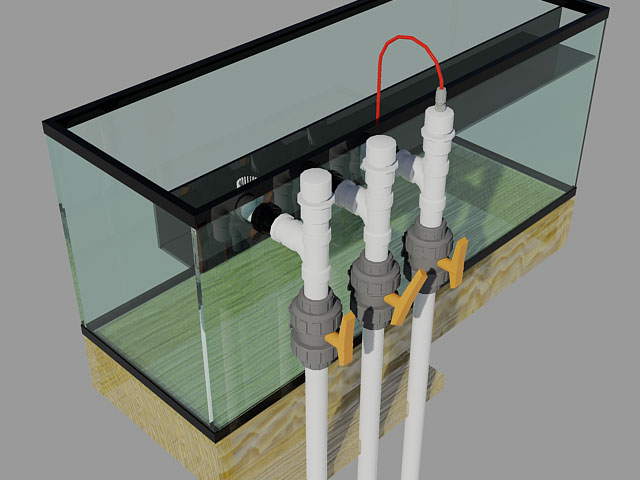

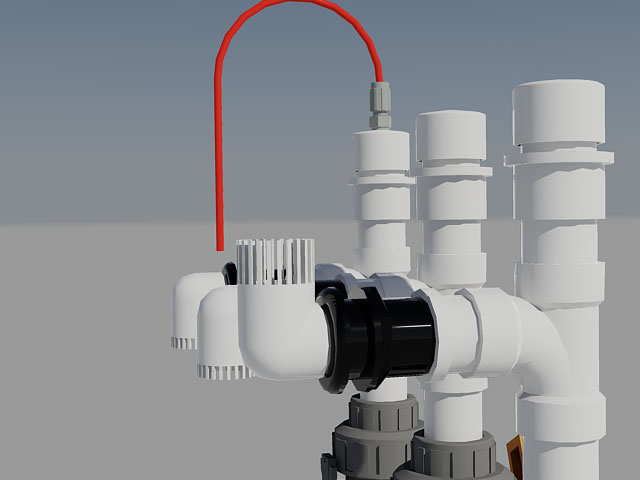

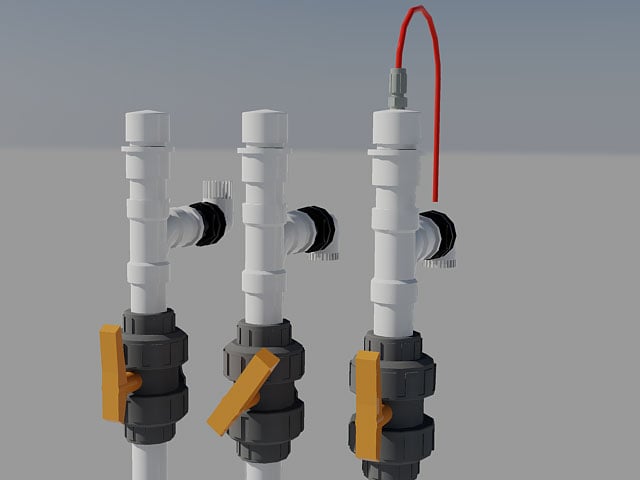

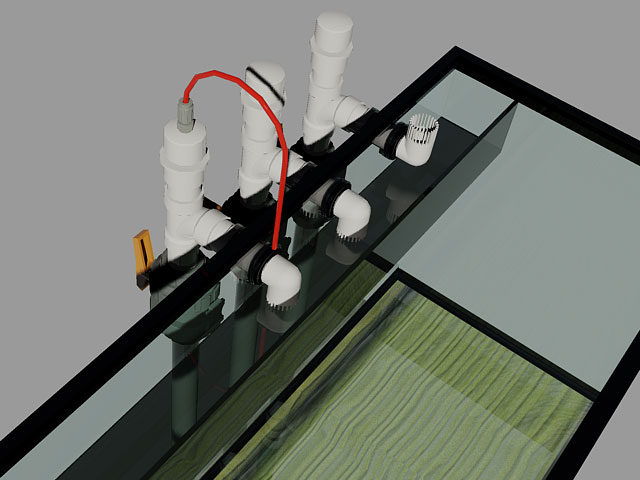

So, I am now planning how I want to set up the 55. I think I want drilled overflows. I don't want to deal with HOB and all the issues associated anymore. So, I was thinking dual 3/4" or 1" overflows. Overkill, I know, but I want one overflow to be able to handle all the water in the case that the other clogs for any reason. So, I'm just looking for input on what you all think would be a good, as fool proof as possible set up.

I have a 55 gallon tank, and am planning on breaking it down due to multiple issues (algae mainly) and want to set it up again the proper way (using RO/DI water...).

I am currently using a HOB overflow that uses an aqualifter pump to pull air out of the U-tube. Today that pump decided to quit, and luckily I noticed the high water levels before overflow slowed down enough that the tank overflowed. For the night I manually sucked the air out of the U-tube, I'll look into replacing the pump tomorrow. (and set up the ten gallon tank my two clownfish will live in until the 55 is set up again).

So, I am now planning how I want to set up the 55. I think I want drilled overflows. I don't want to deal with HOB and all the issues associated anymore. So, I was thinking dual 3/4" or 1" overflows. Overkill, I know, but I want one overflow to be able to handle all the water in the case that the other clogs for any reason. So, I'm just looking for input on what you all think would be a good, as fool proof as possible set up.