snakeblitz33

Well-Known Member

Hello Guys and Gals,

My wife and I talked about setting up a 180g next year after we move and get established and into a routine. This tank is not going to be built for a very, very long time. It may evolve into something completely different over the next year. This is just a design that I am kicking around in my head for the time being. I want ya'lls opinions and suggestions. I'm really open to anything at the moment. I know one thing for sure: This tank will be an SPS and Clam dominated tank.

This will be my lifelong personal tank. I don't plan on going bigger than this, ever. I've had a 240g before, and it was a pain in the butt to maintain. I also like Acrylic because you can always modify it and tune it to the way you want to do things. It's a lot more forgiving than glass over the lifetime of the tank.

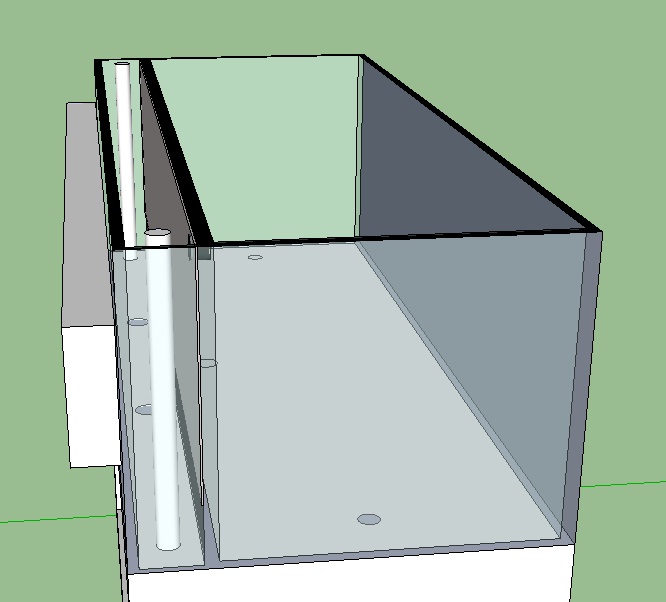

This is what I am thinking so far: Tank: 72x24x24 Rear Chamber: 3.5x72

The tank will be custom built out of 3/4" acrylic. Solid built! I don't mind paying the extra for something so sturdy. Also, the back acrylic will be black. I know, more expensive, but it's completely worth it for aesthetics. I'm building it myself. The two standpipe looking things are actually returns on either side of the tank. The two middle holes/bulkheads are 1 1/2" drains. The top will be eurobraced, I couldn't figure out how to do it in Google Sketchup.

The returns will push water into the tank on either side from the sump. The water will overflow evenly across the back of the tank down a (few) algae scrubber screens that will be maintained often. Of course, teeth will be cut out at the top of the black acrylic. The rectangular box thing on the back of the tank is a T5HO freshwater light 4x unit, that will be mounted on the wall behind the tank, and easily removed when necessary. This tank is big enough to have a closed loop, which is exactly what I am going to do.

The Closed Loop: Maybe running a Reeflo Dart on an Oceans Motions four way unit. The Dart is rated at 3800gph at 0ft of head, so that will put it at 21x internal turnover rate. Instead of two closed loop returns in the picture, I plan on having four. Two in front, blowing at the corals and two on the sides. Hopefully, I can get some decent water flow going through the system. I'm going to play with the loclines quite a bit.

The Sump: I plan on having a lot of open space underneath the tank. I plan on using a custom built sump, 20x36x20. I want the other half of the underneath of the stand for equipment. The sump will have a small space for a sand bed and macro refugium, just in case I want to customize it more. I'm going to use a three tier box filtration system, carbon pillow, GFO pillow, and filter floss. Maybe run a Polyfilter in it occasionally. I plan on having most of the live rock in the sump and in the DT, two small islands connected by an "overpass." you get the idea.

The Equipment: Recirc skimmer, I'm thinking an Octopus, ASM or SWC Cone. Something pretty substantial to back up the algae scrubber. I'm also going to invest in a calcium reactor and a kalkwasser stirrer. I have never personally used one, however, I am extremely intrigued and ready to step it up a notch. For lighting, I plan on 3, 250w 14k metal halides backed by four actinic true blue T5HO lamps. The lighting system will be mounted in a canopy until it's moved into a more permanent location (A house.) I've heard a great deal about Vortech pumps, and IF NEEDED I may invest in a couple of MP40s for the sides of the tank.

Questions:

1. Do you think that the Reeflo Dart would be a good choice for the 180 SPS reef?

2. Do you think that going barebottom would make the tank run too sterile for the intended inhabitants?

3. With such a large algae scrubber, do you think it would even be necessary to run a skimmer, at least at first?

4. Is there any modifications that you can think of?

5. If I run an algae scrubber and a skimmer on this tank with such a low bioload, do you think the tank would run too sterile?

6. Does the algae scrubber running on the back of the tank sound like a good idea? I think it does... it should also be easy to remove and clean. The screens will be broken up into fourths, and clean two at a time.

7. If you have any questions, PLEASE feel free to ask. I really need some critiques on this tank design. I want to get it as improved as I can before it's build time.

Thanks Guys and Gals.

My wife and I talked about setting up a 180g next year after we move and get established and into a routine. This tank is not going to be built for a very, very long time. It may evolve into something completely different over the next year. This is just a design that I am kicking around in my head for the time being. I want ya'lls opinions and suggestions. I'm really open to anything at the moment. I know one thing for sure: This tank will be an SPS and Clam dominated tank.

This will be my lifelong personal tank. I don't plan on going bigger than this, ever. I've had a 240g before, and it was a pain in the butt to maintain. I also like Acrylic because you can always modify it and tune it to the way you want to do things. It's a lot more forgiving than glass over the lifetime of the tank.

This is what I am thinking so far: Tank: 72x24x24 Rear Chamber: 3.5x72

The tank will be custom built out of 3/4" acrylic. Solid built! I don't mind paying the extra for something so sturdy. Also, the back acrylic will be black. I know, more expensive, but it's completely worth it for aesthetics. I'm building it myself. The two standpipe looking things are actually returns on either side of the tank. The two middle holes/bulkheads are 1 1/2" drains. The top will be eurobraced, I couldn't figure out how to do it in Google Sketchup.

The returns will push water into the tank on either side from the sump. The water will overflow evenly across the back of the tank down a (few) algae scrubber screens that will be maintained often. Of course, teeth will be cut out at the top of the black acrylic. The rectangular box thing on the back of the tank is a T5HO freshwater light 4x unit, that will be mounted on the wall behind the tank, and easily removed when necessary. This tank is big enough to have a closed loop, which is exactly what I am going to do.

The Closed Loop: Maybe running a Reeflo Dart on an Oceans Motions four way unit. The Dart is rated at 3800gph at 0ft of head, so that will put it at 21x internal turnover rate. Instead of two closed loop returns in the picture, I plan on having four. Two in front, blowing at the corals and two on the sides. Hopefully, I can get some decent water flow going through the system. I'm going to play with the loclines quite a bit.

The Sump: I plan on having a lot of open space underneath the tank. I plan on using a custom built sump, 20x36x20. I want the other half of the underneath of the stand for equipment. The sump will have a small space for a sand bed and macro refugium, just in case I want to customize it more. I'm going to use a three tier box filtration system, carbon pillow, GFO pillow, and filter floss. Maybe run a Polyfilter in it occasionally. I plan on having most of the live rock in the sump and in the DT, two small islands connected by an "overpass." you get the idea.

The Equipment: Recirc skimmer, I'm thinking an Octopus, ASM or SWC Cone. Something pretty substantial to back up the algae scrubber. I'm also going to invest in a calcium reactor and a kalkwasser stirrer. I have never personally used one, however, I am extremely intrigued and ready to step it up a notch. For lighting, I plan on 3, 250w 14k metal halides backed by four actinic true blue T5HO lamps. The lighting system will be mounted in a canopy until it's moved into a more permanent location (A house.) I've heard a great deal about Vortech pumps, and IF NEEDED I may invest in a couple of MP40s for the sides of the tank.

Questions:

1. Do you think that the Reeflo Dart would be a good choice for the 180 SPS reef?

2. Do you think that going barebottom would make the tank run too sterile for the intended inhabitants?

3. With such a large algae scrubber, do you think it would even be necessary to run a skimmer, at least at first?

4. Is there any modifications that you can think of?

5. If I run an algae scrubber and a skimmer on this tank with such a low bioload, do you think the tank would run too sterile?

6. Does the algae scrubber running on the back of the tank sound like a good idea? I think it does... it should also be easy to remove and clean. The screens will be broken up into fourths, and clean two at a time.

7. If you have any questions, PLEASE feel free to ask. I really need some critiques on this tank design. I want to get it as improved as I can before it's build time.

Thanks Guys and Gals.