cipher43

Member

So I am in need of all of your help here. I am planning on putting a scrubber on my new tank (120g+40G sump) and my moms tank (55G+20g sump) after I finish the stands for the 2. So for my moms tank I plan on using a 6"X 12" screen and my tank i am planning on using an 12"X14" ish screen for mine.

So the first question is how many GPH do i need for each of the scrubbers. Right now her tank has a return that puts out 550 GPH or under after headloss in her tank. I do plan on putting the return pump off of my 30 gallon on her tank aswell when i upgrade so she will have two returns for more umph cause her tank always has a layer of stuff on the top of the water. will that be enough for her scrubber or will i need to use a different pump? As for my tank i plan on getting a pump that will give me around 900GPH after head loss. As of right now i do plan to avoid adding another pump to the systems and just using the overflows on each.

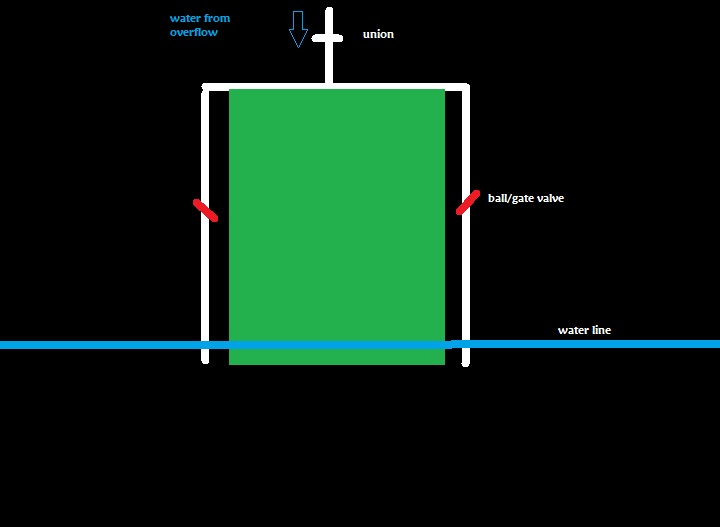

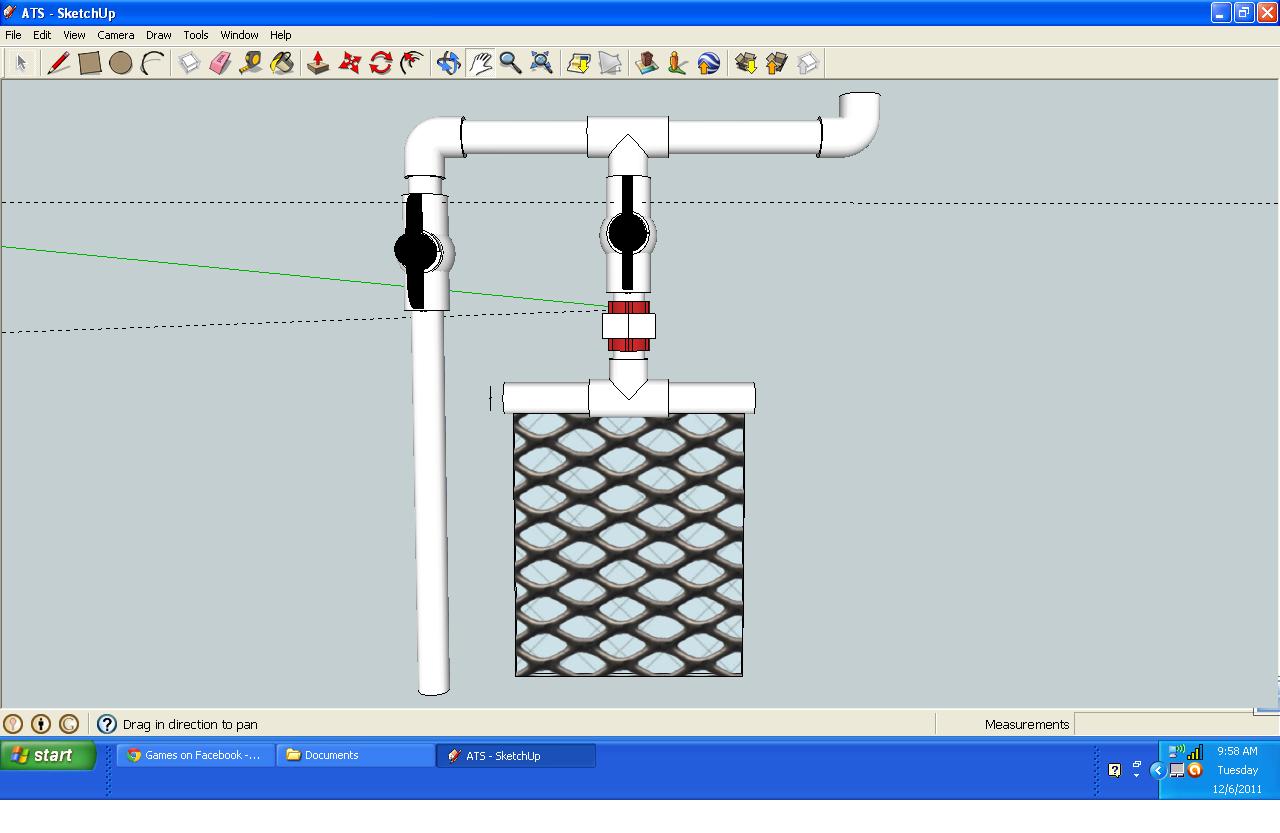

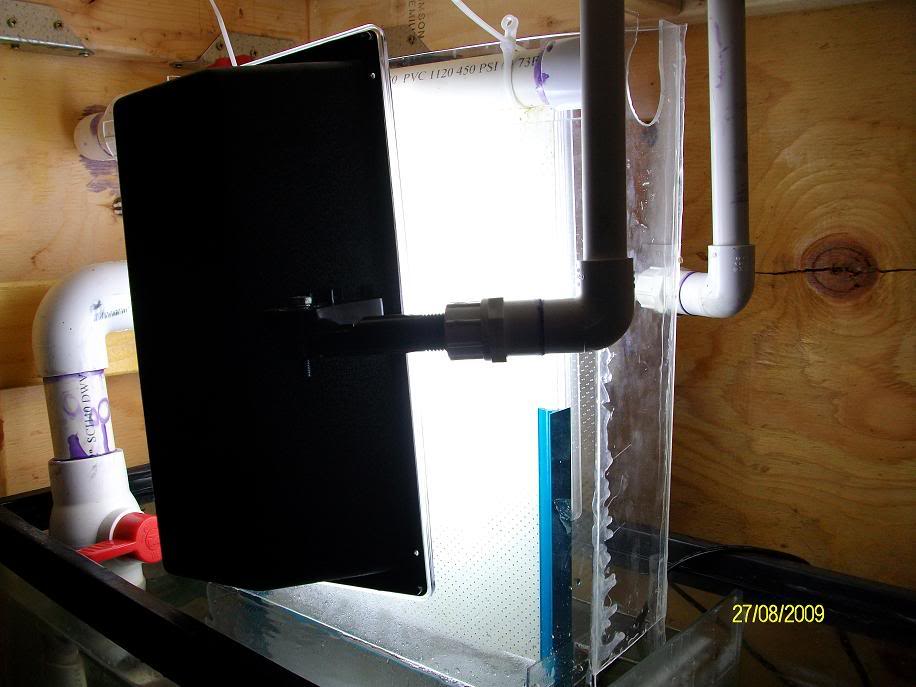

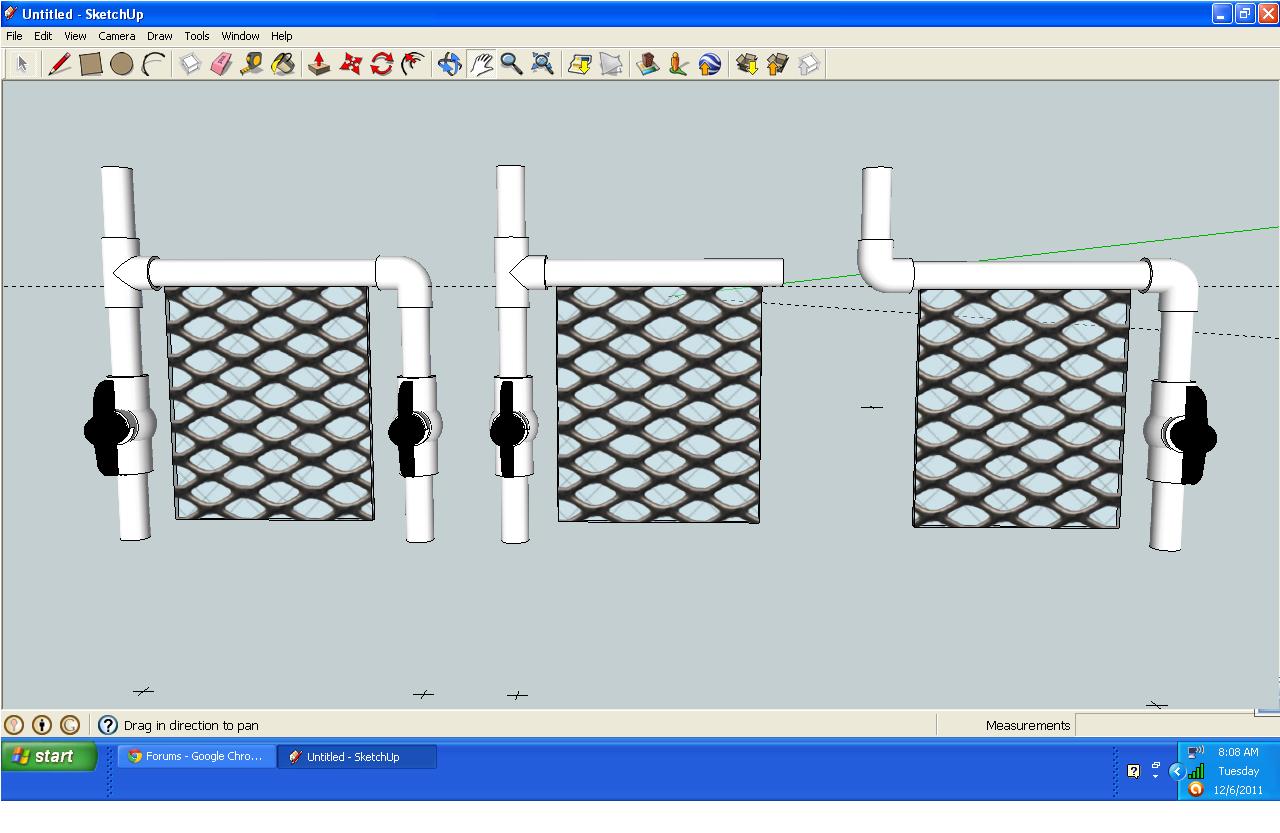

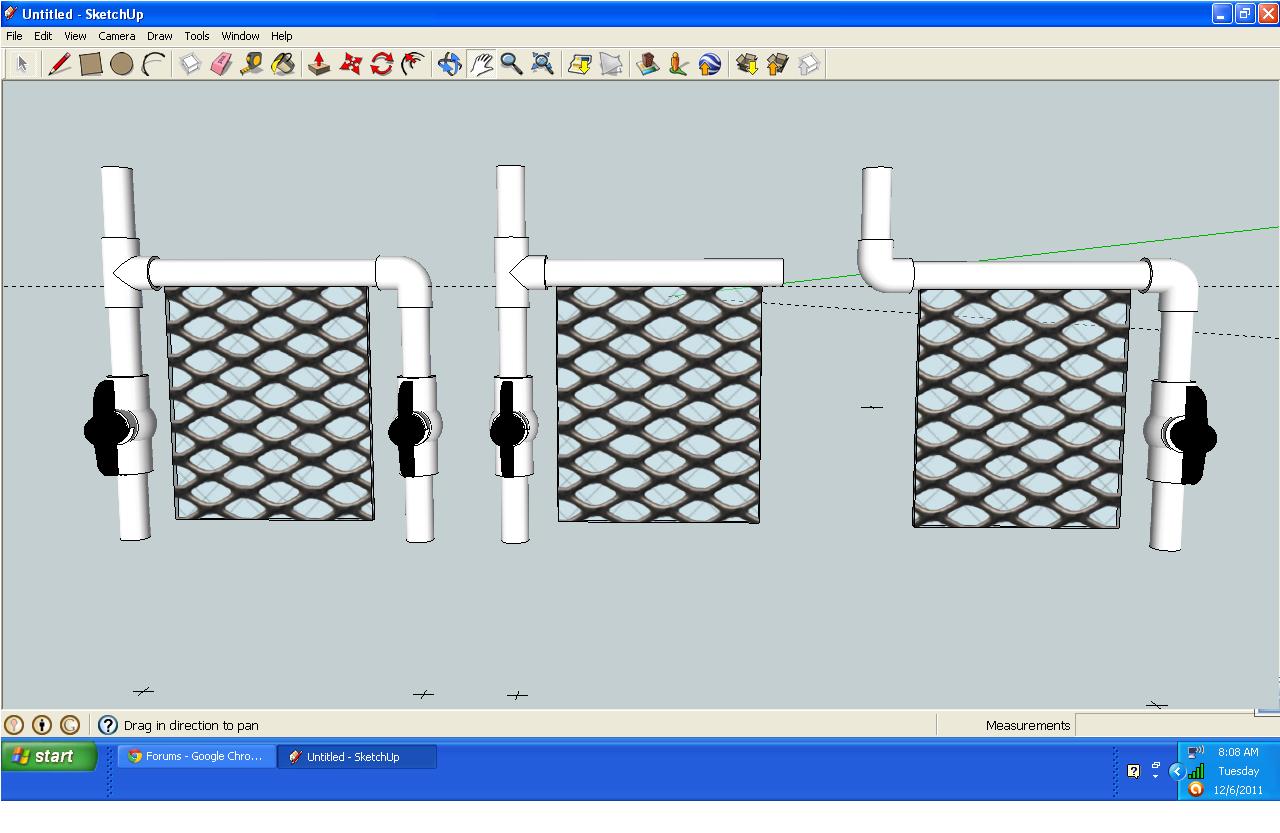

Second question is about design. I have been trying to think about a good way of doing it and I think i have it narrowed down now so i wanted all of your opinions.

At the moment i am thinking of ding the one thats on the far left because i would be able to adjust the flow and still have the water flow through when the ATS is removed. I couldnt find a union that would work on google sketchup but i do plan on having a union off of the T to remove the ATS.

So what do you guys think?

So the first question is how many GPH do i need for each of the scrubbers. Right now her tank has a return that puts out 550 GPH or under after headloss in her tank. I do plan on putting the return pump off of my 30 gallon on her tank aswell when i upgrade so she will have two returns for more umph cause her tank always has a layer of stuff on the top of the water. will that be enough for her scrubber or will i need to use a different pump? As for my tank i plan on getting a pump that will give me around 900GPH after head loss. As of right now i do plan to avoid adding another pump to the systems and just using the overflows on each.

Second question is about design. I have been trying to think about a good way of doing it and I think i have it narrowed down now so i wanted all of your opinions.

At the moment i am thinking of ding the one thats on the far left because i would be able to adjust the flow and still have the water flow through when the ATS is removed. I couldnt find a union that would work on google sketchup but i do plan on having a union off of the T to remove the ATS.

So what do you guys think?