topofsteel

Member

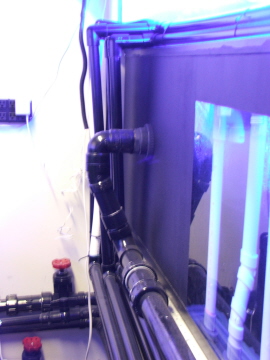

I have a 115 gallon tank with an overflow drilled for supply and return that I'm about to set up. I'm not really in the position to take it and have it drilled for a closed loop system. But it has a custom canopy with extra room.

What I was wondering is if I could put a pump in the canopy to suck water up and direct it back into the tank. Many pumps say they need to be submerged, I would need one that could start dry. Has anyone done this? Does this sound like a good/bad idea? Are there any other considerations you can think of? Thanks.

What I was wondering is if I could put a pump in the canopy to suck water up and direct it back into the tank. Many pumps say they need to be submerged, I would need one that could start dry. Has anyone done this? Does this sound like a good/bad idea? Are there any other considerations you can think of? Thanks.