saltn00b

Active Member

hi all. I will be getting my Sequence DART to push my CLS this week. the drain is already plumbed, and the Dart will be mounted on the underside of the tank on the left side. (upsidedown from the stand ceiling)

So now the question is, what is the best way to build the manifold?

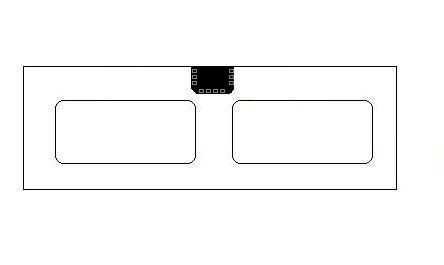

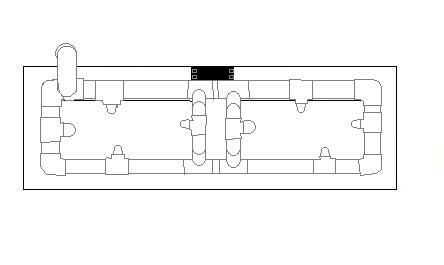

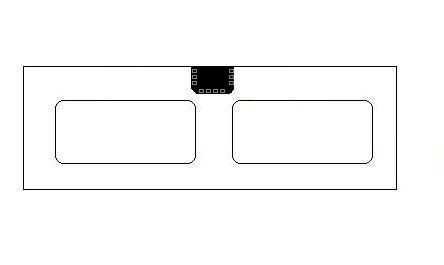

here is the top of my acrylic custom 150g:

it has about a 3" lip around the top and then a rectangle cut out in the middle-back for the overflow column in black. i post this so it is easy for you to take the pic and draw your ideas on it and post up! think of it like a template

ok so i had two ideas

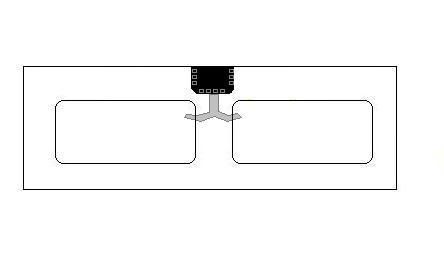

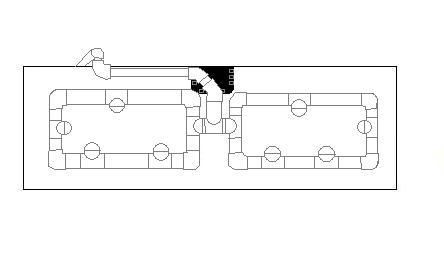

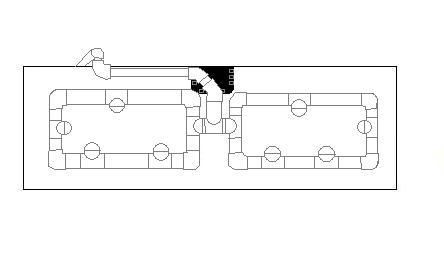

option 1:

i think with this version it is possible the left side may get a lot more push than then the right. Although, the concept behind a manifold, where the PVC is built in a Ring formation, pressure stays even.

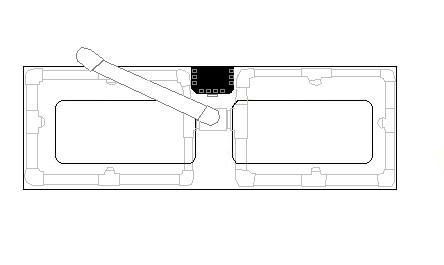

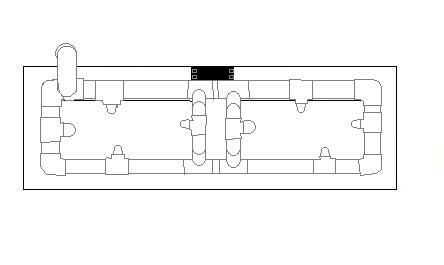

option 2:

any input would be great!

sorry for double posting but this will be in my upgrade thread as well.

So now the question is, what is the best way to build the manifold?

here is the top of my acrylic custom 150g:

it has about a 3" lip around the top and then a rectangle cut out in the middle-back for the overflow column in black. i post this so it is easy for you to take the pic and draw your ideas on it and post up! think of it like a template

ok so i had two ideas

option 1:

i think with this version it is possible the left side may get a lot more push than then the right. Although, the concept behind a manifold, where the PVC is built in a Ring formation, pressure stays even.

option 2:

any input would be great!

sorry for double posting but this will be in my upgrade thread as well.