rabid frog

Active Member

Ok so our reef club is having a DIY Nano build off that is to run for the span of 6 months. The goal is to stay under $200.00 and 10 gallon or less

. Here is what I have so far. I used 1/4" acrylic for this tank. I am building my own "Canister" filter for the tank also.

I am using the old lights from my aquapod, but I still have to build a canopy for it. I have a huge drain 1 1/2" that I am going to use for a stand pipe to drain into the filter. I am using 1/4" pvc for returns , which I have drilled for bulk heads and lockline returns.

Hopefully I will use my mag 5 pump that I have laying around. I am putting a ball valve on the return side so I can choke down the pump if it is too much flow. Undoubtly it will be a little too much flow.

Enough bable onto the pictures.

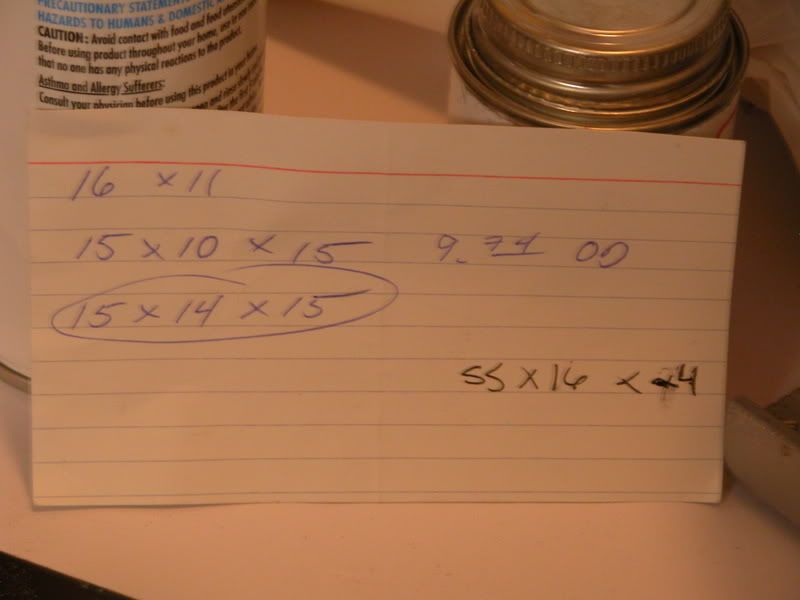

The complicated autocad drawings

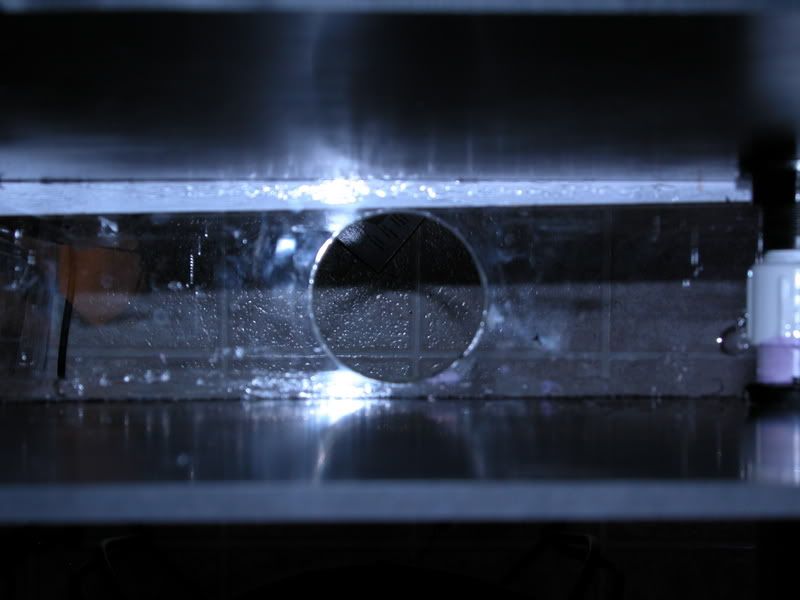

Showing the back chamber

Clamps i used to make sure the tank was square. Harbor freight 1.39 each.

Holes drilled for returns and back wall painted black. Krylon Fusion

With lock line returns and bulk heads installed. I ended up taking all but one link of lockline off. The returns were too long imo.

Hope you enjoy. I realize from the plans the actual dimensions of the tank are not 10 gallons. But I have the back plate moved up so the main tank is 10" from back to front. So the main tank size is 10x14x15 which turns out to be about 9.09 gallons. But I am running the tank with the water line to be about 1" low so that gives me another gallon to play with in the sump/canister filter.

I guess what I ended up doing was building a reef ready aquapod.. lol. Or an aquapod the it almost should have been built.

. Here is what I have so far. I used 1/4" acrylic for this tank. I am building my own "Canister" filter for the tank also.

I am using the old lights from my aquapod, but I still have to build a canopy for it. I have a huge drain 1 1/2" that I am going to use for a stand pipe to drain into the filter. I am using 1/4" pvc for returns , which I have drilled for bulk heads and lockline returns.

Hopefully I will use my mag 5 pump that I have laying around. I am putting a ball valve on the return side so I can choke down the pump if it is too much flow. Undoubtly it will be a little too much flow.

Enough bable onto the pictures.

The complicated autocad drawings

Showing the back chamber

Clamps i used to make sure the tank was square. Harbor freight 1.39 each.

Holes drilled for returns and back wall painted black. Krylon Fusion

With lock line returns and bulk heads installed. I ended up taking all but one link of lockline off. The returns were too long imo.

Hope you enjoy. I realize from the plans the actual dimensions of the tank are not 10 gallons. But I have the back plate moved up so the main tank is 10" from back to front. So the main tank size is 10x14x15 which turns out to be about 9.09 gallons. But I am running the tank with the water line to be about 1" low so that gives me another gallon to play with in the sump/canister filter.

I guess what I ended up doing was building a reef ready aquapod.. lol. Or an aquapod the it almost should have been built.