cj7eagle

Member

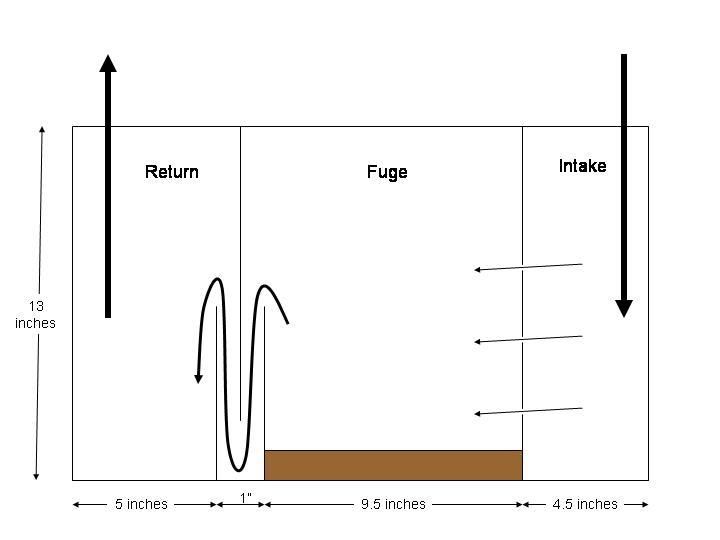

I am making this out of a 10 gallon tank for my 29 gallon tank. I plan on using my SS65 skimmer as a HOB with the skimmer sitting in the fuge, and the pump sitting in the intake area. That piece will be solid top to bottom with holes drilled through it for the water to pass into the fuge. then through the zig zag to the return. Then using a mag 5 or 7 to pump it back into the tank.

questions...

how deep do i want the water?

Where should i drill the holes in the first divider? how many and what size will be sufficient?

What do i want for a sand bed in the fuge? regular live sand? or would I be better off with a miracle mud of some sort.

Then all thats left to figure out is what lengths to make my baffles at the end so that water is able to flow through.

any thoughts, or ideas would be great.