double sump

- Thread starter bpro32

- Start date

snakeblitz33

Well-Known Member

Simply put,... no.

You could however have to separate plastic food grade Rubbermaid or plastic food grade containers, establish a link with a couple of bulkheads and you should be good to go.

You could however have to separate plastic food grade Rubbermaid or plastic food grade containers, establish a link with a couple of bulkheads and you should be good to go.

turningtim

Active Member

Um, yes you can. But you have to use boxes (HOB OF stlye) on each side to ensure that you don't lose siphon in power out. You also have to make the tops of the tanks level. So by lifting the shorter one up you should be fine. This will allow you to use both fuge and sump for backwash room.

You also need to know how much flow you going to have traveling through the sump for sizing. I have helped design systems that use this type of transfer and it does work if you set it up correctly.

On a side note it would be much easier to just use a Dremel and drill both tanks in the side and use a BH and pipe to connect.

You need some help just ask!

HTH

Tim

You also need to know how much flow you going to have traveling through the sump for sizing. I have helped design systems that use this type of transfer and it does work if you set it up correctly.

On a side note it would be much easier to just use a Dremel and drill both tanks in the side and use a BH and pipe to connect.

You need some help just ask!

HTH

Tim

scsinet

Active Member

Originally Posted by TurningTim

http:///forum/post/2598322

Um, yes you can. But you have to use boxes (HOB OF stlye) on each side to ensure that you don't lose siphon in power out. You also have to make the tops of the tanks level. So by lifting the shorter one up you should be fine. This will allow you to use both fuge and sump for backwash room.

You also need to know how much flow you going to have traveling through the sump for sizing. I have helped design systems that use this type of transfer and it does work if you set it up correctly.

On a side note it would be much easier to just use a Dremel and drill both tanks in the side and use a BH and pipe to connect.

You need some help just ask!

HTH

Tim

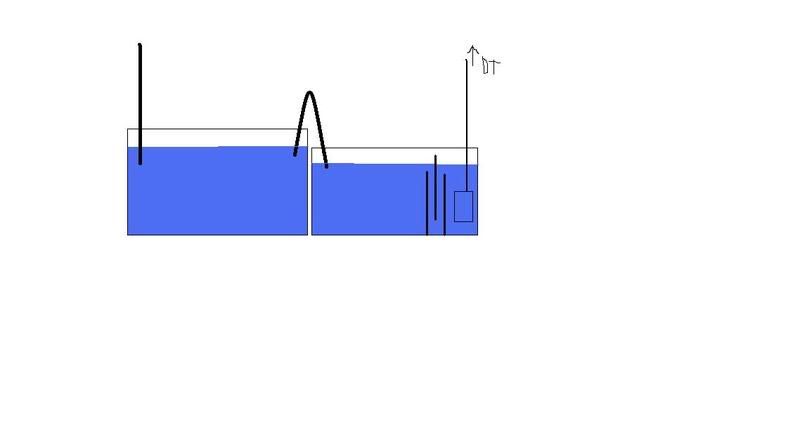

From what it looks like, he's got a baffle separating the return section from the compartment with the U-Tube in it.

So, the left hand tank and U-Tube compartment of the right hand side should remain full, so in theory, the U-Tube would work without overflow boxes.

bpro, the water level of the two sides linked by the U-Tube will want to stay even. A siphon is merely water attempting to level itself. So, in addition to what Tim was saying about the two aquariums being level, the top edge of the baffle of the right hand tank must be at the same height as the water level of the left hand tank.

However, this design is not what I'd call reliable. A far better (from a sleep-at-night perspective) is to drill the two sides and link them together with a bulkhead.

http:///forum/post/2598322

Um, yes you can. But you have to use boxes (HOB OF stlye) on each side to ensure that you don't lose siphon in power out. You also have to make the tops of the tanks level. So by lifting the shorter one up you should be fine. This will allow you to use both fuge and sump for backwash room.

You also need to know how much flow you going to have traveling through the sump for sizing. I have helped design systems that use this type of transfer and it does work if you set it up correctly.

On a side note it would be much easier to just use a Dremel and drill both tanks in the side and use a BH and pipe to connect.

You need some help just ask!

HTH

Tim

From what it looks like, he's got a baffle separating the return section from the compartment with the U-Tube in it.

So, the left hand tank and U-Tube compartment of the right hand side should remain full, so in theory, the U-Tube would work without overflow boxes.

bpro, the water level of the two sides linked by the U-Tube will want to stay even. A siphon is merely water attempting to level itself. So, in addition to what Tim was saying about the two aquariums being level, the top edge of the baffle of the right hand tank must be at the same height as the water level of the left hand tank.

However, this design is not what I'd call reliable. A far better (from a sleep-at-night perspective) is to drill the two sides and link them together with a bulkhead.

turningtim

Active Member

DUH! You're right SCSI! I for some reason thinking that the sump would lose water not gain water in power out!

Still pretty risky w/o boxes and cutting holes in 3/16"-1/4" glass is easy!

Meds haven't kicked in yet this morning!

Thanks SCSI!

Tim

Still pretty risky w/o boxes and cutting holes in 3/16"-1/4" glass is easy!

Meds haven't kicked in yet this morning!

Thanks SCSI!

Tim

scsinet

Active Member

What size tanks are they?

10g and under can be tough... but it can be done. On the flip side, they are easy to learn with because if you break one, it's only $10 to buy another.

I actually have a CPR wet dry plumbed to a 10G auxillary return reservoir on my 120g planted FW tank this way.

... oh, and the first one I drilled I broke, but it was when I was tightening the bulkhead.

If you are using 10g tanks, what I did that helped me out was I cut a 4x4" piece of 1/4" acrylic, and drilled a hole in the center the same size as the one I drilled in the glass (but of course using a suitable hole saw for cutting plastic, not the diamond one). Then I placed it on the locknut side of the bulkhead between the locknut and glass. IMO it helps reinforce and reduces stress on the glass. Also, when you set everything up, screwing some wood strips down to the shelf where they sit to keep the sumps from shifting is a good idea. If you bump the sumps with a hard pipe in between it can crack the glass. Finally, spa flex is better for joining the two bulkheads vs. hard pipe. Again, more forgiving, less stress.

10g and under can be tough... but it can be done. On the flip side, they are easy to learn with because if you break one, it's only $10 to buy another.

I actually have a CPR wet dry plumbed to a 10G auxillary return reservoir on my 120g planted FW tank this way.

... oh, and the first one I drilled I broke, but it was when I was tightening the bulkhead.

If you are using 10g tanks, what I did that helped me out was I cut a 4x4" piece of 1/4" acrylic, and drilled a hole in the center the same size as the one I drilled in the glass (but of course using a suitable hole saw for cutting plastic, not the diamond one). Then I placed it on the locknut side of the bulkhead between the locknut and glass. IMO it helps reinforce and reduces stress on the glass. Also, when you set everything up, screwing some wood strips down to the shelf where they sit to keep the sumps from shifting is a good idea. If you bump the sumps with a hard pipe in between it can crack the glass. Finally, spa flex is better for joining the two bulkheads vs. hard pipe. Again, more forgiving, less stress.

fishfreak1242

Active Member

I have thought an idea! You can have the two tanks next to each with an overflow t-ed off so that half the water goes to one section and the other half to the other tank. Then you could get an external pump as the return in between the tanks that will also be t-ed off so that it is taking water from both tanks and returning to your DT.

bpro32

Member

Originally Posted by fishfreak1242

http:///forum/post/2598706

I have thought an idea! You can have the two tanks next to each with an overflow t-ed off so that half the water goes to one section and the other half to the other tank. Then you could get an external pump as the return in between the tanks that will also be t-ed off so that it is taking water from both tanks and returning to your DT.

Will that reduce the flow from the external?

http:///forum/post/2598706

I have thought an idea! You can have the two tanks next to each with an overflow t-ed off so that half the water goes to one section and the other half to the other tank. Then you could get an external pump as the return in between the tanks that will also be t-ed off so that it is taking water from both tanks and returning to your DT.

Will that reduce the flow from the external?

bpro32

Member

Originally Posted by SCSInet

http:///forum/post/2598689

What size tanks are they?

10g and under can be tough... but it can be done. On the flip side, they are easy to learn with because if you break one, it's only $10 to buy another.

I actually have a CPR wet dry plumbed to a 10G auxillary return reservoir on my 120g planted FW tank this way.

... oh, and the first one I drilled I broke, but it was when I was tightening the bulkhead.

If you are using 10g tanks, what I did that helped me out was I cut a 4x4" piece of 1/4" acrylic, and drilled a hole in the center the same size as the one I drilled in the glass (but of course using a suitable hole saw for cutting plastic, not the diamond one). Then I placed it on the locknut side of the bulkhead between the locknut and glass. IMO it helps reinforce and reduces stress on the glass. Also, when you set everything up, screwing some wood strips down to the shelf where they sit to keep the sumps from shifting is a good idea. If you bump the sumps with a hard pipe in between it can crack the glass. Finally, spa flex is better for joining the two bulkheads vs. hard pipe. Again, more forgiving, less stress.

I am using a 10 and a 20. I was already planning on using the flex if I can get this done. Which side is the locknut side? The side without the rubber correct?

http:///forum/post/2598689

What size tanks are they?

10g and under can be tough... but it can be done. On the flip side, they are easy to learn with because if you break one, it's only $10 to buy another.

I actually have a CPR wet dry plumbed to a 10G auxillary return reservoir on my 120g planted FW tank this way.

... oh, and the first one I drilled I broke, but it was when I was tightening the bulkhead.

If you are using 10g tanks, what I did that helped me out was I cut a 4x4" piece of 1/4" acrylic, and drilled a hole in the center the same size as the one I drilled in the glass (but of course using a suitable hole saw for cutting plastic, not the diamond one). Then I placed it on the locknut side of the bulkhead between the locknut and glass. IMO it helps reinforce and reduces stress on the glass. Also, when you set everything up, screwing some wood strips down to the shelf where they sit to keep the sumps from shifting is a good idea. If you bump the sumps with a hard pipe in between it can crack the glass. Finally, spa flex is better for joining the two bulkheads vs. hard pipe. Again, more forgiving, less stress.

I am using a 10 and a 20. I was already planning on using the flex if I can get this done. Which side is the locknut side? The side without the rubber correct?

scsinet

Active Member

Originally Posted by fishfreak1242

http:///forum/post/2598706

I have thought an idea! You can have the two tanks next to each with an overflow t-ed off so that half the water goes to one section and the other half to the other tank. Then you could get an external pump as the return in between the tanks that will also be t-ed off so that it is taking water from both tanks and returning to your DT.

Unfortuantely this won't work.

You have no way of ensuring that an even amount of water is being pumped in or out of either tank. It'll flood.

http:///forum/post/2598706

I have thought an idea! You can have the two tanks next to each with an overflow t-ed off so that half the water goes to one section and the other half to the other tank. Then you could get an external pump as the return in between the tanks that will also be t-ed off so that it is taking water from both tanks and returning to your DT.

Unfortuantely this won't work.

You have no way of ensuring that an even amount of water is being pumped in or out of either tank. It'll flood.

scsinet

Active Member

Originally Posted by bpro32

http:///forum/post/2599459

I am using a 10 and a 20. I was already planning on using the flex if I can get this done. Which side is the locknut side? The side without the rubber correct?

Correct.

http:///forum/post/2599459

I am using a 10 and a 20. I was already planning on using the flex if I can get this done. Which side is the locknut side? The side without the rubber correct?

Correct.

aratroth

Member

I would also vote for drilling the two tanks rather than relying on a siphon to keep water levels in tact because of the risk of a power outage. I recently drilled my 20g fuge and it was surprisingly easier than I had thought. Just get some plumbers putty and make a border around where you want to drill the hole, full this border with water and go SLOWLY as you drill the glass. Also if you have any extra pieces of glass lying around, or can get your hands on any, buy some and practice as many times as you can on the test glass. I didnt have any breaking or cracking issues on any of the holes that I drilled, but if you do this, remember that patience is most definitely key here...do not rush with the drill or you will most likely crack the glass.

just my .02

just my .02

turningtim

Active Member

Here is a way I was thinking of attaching two sump tanks. These are in an L layout but could work for a straight layout. Both tanks where leveled at the top. One BH with a piece of 2" pipe in between the tanks. Gaskets on both sides. I also placed them further down in the tanks so I could control water height. The stubs out of the BH will have EL's and then added pipe to the proper water level either up or down depending on the side.

No water pressure involved here so you should have to crank down on the BH's and this way it is much easier to remove and move the tanks around if needed. No glue!

How are you going to cut the holes? Dremel or diamond hole saw?

HTH

Tim

No water pressure involved here so you should have to crank down on the BH's and this way it is much easier to remove and move the tanks around if needed. No glue!

How are you going to cut the holes? Dremel or diamond hole saw?

HTH

Tim

turningtim

Active Member

On the bottom of the first page I have pics and the way I drilled my tanks........

https://forums.saltwaterfish.com/t/284317/diy-120-reef-build

Tim

https://forums.saltwaterfish.com/t/284317/diy-120-reef-build

Tim

bpro32

Member

Originally Posted by TurningTim

http:///forum/post/2599657

Here is a way I was thinking of attaching two sump tanks. These are in an L layout but could work for a straight layout. Both tanks where leveled at the top. One BH with a piece of 2" pipe in between the tanks. Gaskets on both sides. I also placed them further down in the tanks so I could control water height. The stubs out of the BH will have EL's and then added pipe to the proper water level either up or down depending on the side.

No water pressure involved here so you should have to crank down on the BH's and this way it is much easier to remove and move the tanks around if needed. No glue!

How are you going to cut the holes? Dremel or diamond hole saw?

HTH

Tim

I haven't picked up the hole saw yet. What do you suggest?

http:///forum/post/2599657

Here is a way I was thinking of attaching two sump tanks. These are in an L layout but could work for a straight layout. Both tanks where leveled at the top. One BH with a piece of 2" pipe in between the tanks. Gaskets on both sides. I also placed them further down in the tanks so I could control water height. The stubs out of the BH will have EL's and then added pipe to the proper water level either up or down depending on the side.

No water pressure involved here so you should have to crank down on the BH's and this way it is much easier to remove and move the tanks around if needed. No glue!

How are you going to cut the holes? Dremel or diamond hole saw?

HTH

Tim

I haven't picked up the hole saw yet. What do you suggest?

turningtim

Active Member

It really depends on if this is the last tank you plan to drill. If so then I would just Dremel them if you already have a dremel. But on the bay there are hole saws really cheap and they work well. I've done a couple of tanks and fuges with the ones I have. i think they were under $25 for both.....

You can also Google "Two part solution" and they have some not sure of the price though!

HTH

Tim

You can also Google "Two part solution" and they have some not sure of the price though!

HTH

Tim