Drilling the back of a nanocube

- Thread starter dempseyjosh

- Start date

dempseyjosh

Member

thanks a bunch! thats what i figured, its just more comforting to hear it from somebody else instead of just assuming

dempseyjosh

Member

Hi,

i've got a couple other questions for ya,

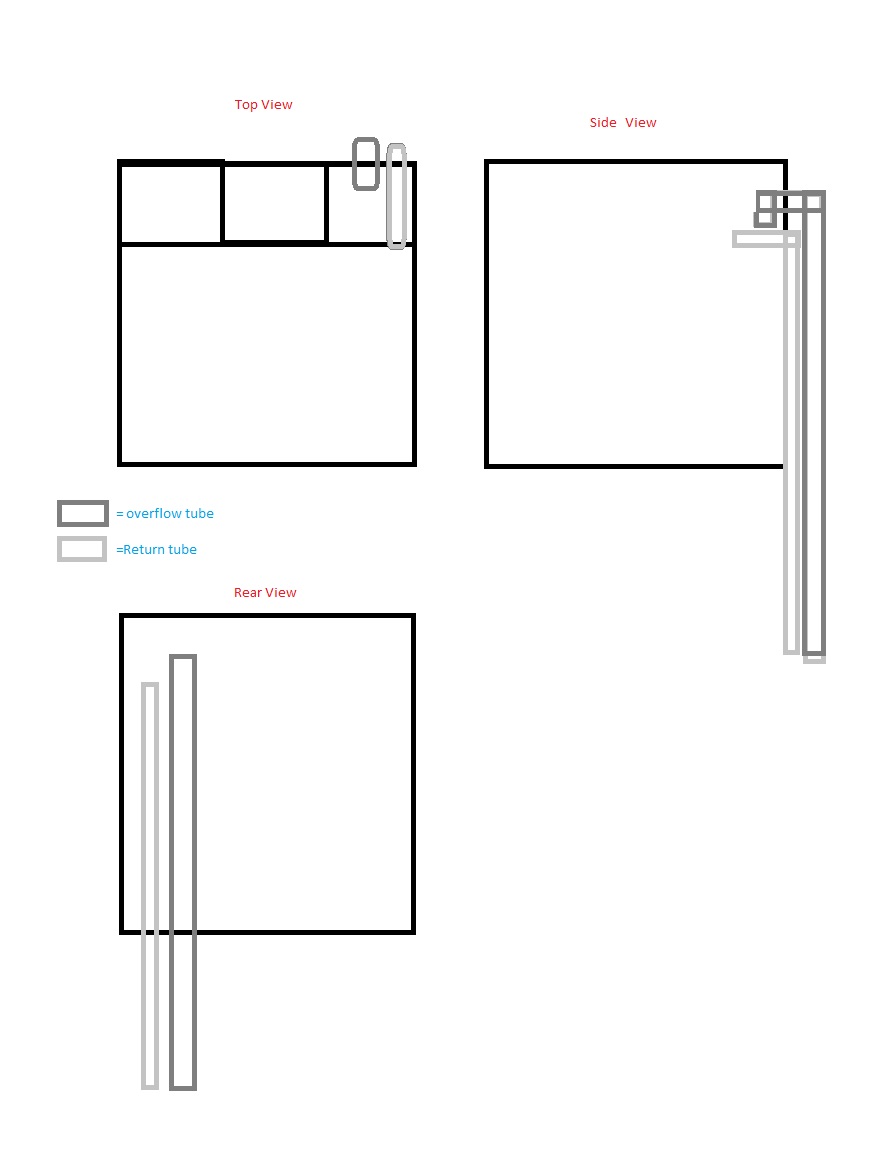

Should I use a larger plumbing for the over flow than I am for the return?

i planned on using 3/4" for the return. i'll be using a mag 2 for the return with about 3 ft of head with one 90 in there.

is 3/4" fine for the overflow? I feel like it is, just want to make sure

And do I really need to have the 90 pointing downward on the overflow, or can that just be open, or with a screen over it? I don't see why its necessary, but i see it on every other design.

i've got a couple other questions for ya,

Should I use a larger plumbing for the over flow than I am for the return?

i planned on using 3/4" for the return. i'll be using a mag 2 for the return with about 3 ft of head with one 90 in there.

is 3/4" fine for the overflow? I feel like it is, just want to make sure

And do I really need to have the 90 pointing downward on the overflow, or can that just be open, or with a screen over it? I don't see why its necessary, but i see it on every other design.

dempseyjosh

Member

thanks,

I was going to make it 1", but then figured i would make it easier on myself by not having to drill 2 different size holes, thus needing to buy 2 hole saw bits.

what about the design with the 90 on it? any thoughts on that?

I was going to make it 1", but then figured i would make it easier on myself by not having to drill 2 different size holes, thus needing to buy 2 hole saw bits.

what about the design with the 90 on it? any thoughts on that?

dempseyjosh

Member

does anyone have any thoughts on that before I get this project under way in the next couple days?

dempseyjosh

Member

yep, that is correct

F

fishhugger

Guest

just did a quick little search and found something you might find usefull, if you havent already considered this.

"When drilling plumbing holes (or holes on the top for feeding access) the best tool is a holesaw, the kind used for putting in deadbolts/doorknobs. When using one, make sure you use plenty of water, these get very hot and will literally melt themselves to the hole. Start by drilling about 1/8" into one side, then flip the acrylic over and drill out the hole, this will keep the acrylic from splintering-out or cracking along the hole edge. Remember to have the plastic supported underneath."

I never wouldve considered the heat when drilling acrylic, but it does make sense.

"When drilling plumbing holes (or holes on the top for feeding access) the best tool is a holesaw, the kind used for putting in deadbolts/doorknobs. When using one, make sure you use plenty of water, these get very hot and will literally melt themselves to the hole. Start by drilling about 1/8" into one side, then flip the acrylic over and drill out the hole, this will keep the acrylic from splintering-out or cracking along the hole edge. Remember to have the plastic supported underneath."

I never wouldve considered the heat when drilling acrylic, but it does make sense.

acrylic51

Active Member

There's honestly no reason to keep the acrylic wet down when drilling. If drilled correctly your cut off material should be a spiral affect coming off kinda like drilling metal and you get the little curly que thing off the bit.....The only reason you'd over heat the material is excessive pressure, or dull bit. I've drilled tons upon tons of holes in acrylic and have never cooled or had it splinter....Now where you will get a splintering affect is using a wood drill bit, drilling smaller holes. In that case your suppose to round the edges over on the drill bit.

acrylic51

Active Member

Quote:

Originally Posted by FishHugger http:///forum/thread/383044/drilling-the-back-of-a-nanocube#post_3347898

just did a quick little search and found something you might find usefull, if you havent already considered this.

"When drilling plumbing holes (or holes on the top for feeding access) the best tool is a holesaw, the kind used for putting in deadbolts/doorknobs. When using one, make sure you use plenty of water, these get very hot and will literally melt themselves to the hole. Start by drilling about 1/8" into one side, then flip the acrylic over and drill out the hole, this will keep the acrylic from splintering-out or cracking along the hole edge. Remember to have the plastic supported underneath."

I never wouldve considered the heat when drilling acrylic, but it does make sense.

FishHugger....have you ever tried wetting down the paper backing on acrylic and then letting it dry and then try removing it? Not the funniest thing in the world.

F

fishhugger

Guest

No I cannot say from experience, but a quick search on 'drilling acrylic' will yeild lots of results suggesting to use some sort of coolant...

Anyways....I have no doubt you are correct, just trying to make sure the OP has taken all things into consideration before he continues with his endeavor.

Anyways....I have no doubt you are correct, just trying to make sure the OP has taken all things into consideration before he continues with his endeavor.

acrylic51

Active Member

dempseyjosh

Member

ok, so ive got everything I need, but now i'm questioning if it is actually acrylic or glass. I thought the front display was clear glass and the back wall and filter compartments were black acrylic.

So I started to drill into the back, and after my first battery went dead in my cordless drill I figured it was no big deal cause I was taking it slow. But then I looked at it from the inside and I could see light coming in. I just figure that it could be clear acrylic covered in a black plastic to make it look nice. So I go at it with my second battery, nice a slow, but when that went dead and I wasn't any further, I began to think this is glass. Does anyone know for sure?

If it is glass, is there a way for me to drill 1.5" holes in it safely?

So I started to drill into the back, and after my first battery went dead in my cordless drill I figured it was no big deal cause I was taking it slow. But then I looked at it from the inside and I could see light coming in. I just figure that it could be clear acrylic covered in a black plastic to make it look nice. So I go at it with my second battery, nice a slow, but when that went dead and I wasn't any further, I began to think this is glass. Does anyone know for sure?

If it is glass, is there a way for me to drill 1.5" holes in it safely?

acrylic51

Active Member

I just went downstairs into my laundry room and checked....I think the back might be glass.....If it is indeed glass it can still be drilled, but you'll need a Dremel or Rotozip, and diamond tip bits. If you have a Lowes nearby I know they carry some of the diamond bits, not sure about HD.....You can also check Harbor Freight the also carry the bits, and are a lot cheaper as well.

http://www.harborfreight.com/catalogsearch/result?category=&q=diamond+coated+bits

Here is a link to bits you'd be looking for, but I think Corey has a better pic of the bits from Harbor Freight......

http://www.harborfreight.com/catalogsearch/result?category=&q=diamond+coated+bits

Here is a link to bits you'd be looking for, but I think Corey has a better pic of the bits from Harbor Freight......

dempseyjosh

Member

why do i need the dremel or rotozip? does it require higher rpms or something? and that link only shows rotary bits that go up to 1/4" doesn't seem right

acrylic51

Active Member

I haven't used them in a regular hand drill. Those bits IME are designed for running in a rotary tool such as a dremel or Rotozip.....They both spin a lot faster than any hand drill would/could....Drilling glass is kinda of misconceiving....your not actually drilling your grinding away the glass.

scsinet

Active Member

Is this a JBJ Nanocube? Unless they've come out with new models, those tanks are glass... at least the two I have are.

Shawn is right, don't bother trying to use dremel bits in a hand drill, they run at maybe 1/20th the speed that dremels do. Besides, a drill has WAY too much torque. If the bit gets twisted in the groove, the drill easily has enough torque to break the glass.

Shawn is right, don't bother trying to use dremel bits in a hand drill, they run at maybe 1/20th the speed that dremels do. Besides, a drill has WAY too much torque. If the bit gets twisted in the groove, the drill easily has enough torque to break the glass.