flower

Well-Known Member

Long story made short. I was upgrading from a 30g long to a 56g tall tank. I had to run both at the same time until I was ready to break down the 30g.

Okay, my problem is this. I put a 20g tall tank under my new stand and in my excitement didn’t add the baffles. Now my display tank is all set up and my sea horses are happy, and now that I’m ready brake down the 30g and move the plumbing to do the sump…I can’t reach the lower tank enough to make a good seal on the baffles.

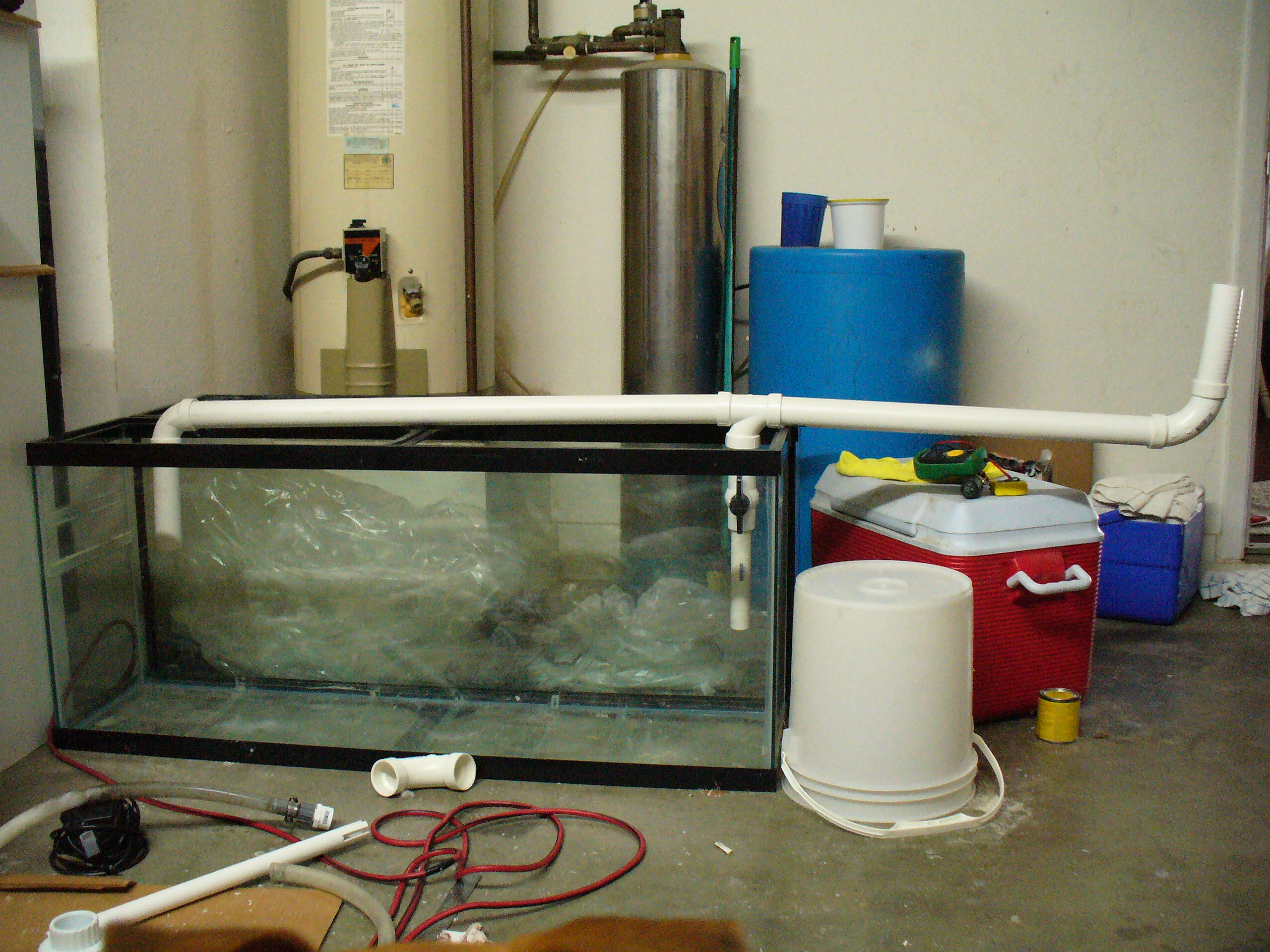

So what I decided to do is keep the 30g sump I already have, and have a sump to the side instead of under the stand.

The sump has three chambers…two chambers are equal, and one chamber on the end is tall and was a refugium section. I would like to keep a refugium and I can turn the sump tank and put the fuge on either end.

Can anyone help……How do I do the plumbing?

Okay, my problem is this. I put a 20g tall tank under my new stand and in my excitement didn’t add the baffles. Now my display tank is all set up and my sea horses are happy, and now that I’m ready brake down the 30g and move the plumbing to do the sump…I can’t reach the lower tank enough to make a good seal on the baffles.

So what I decided to do is keep the 30g sump I already have, and have a sump to the side instead of under the stand.

The sump has three chambers…two chambers are equal, and one chamber on the end is tall and was a refugium section. I would like to keep a refugium and I can turn the sump tank and put the fuge on either end.

Can anyone help……How do I do the plumbing?