Quote:

Originally Posted by

1guyDude http:///forum/thread/386670/internal-overflow#post_3399702

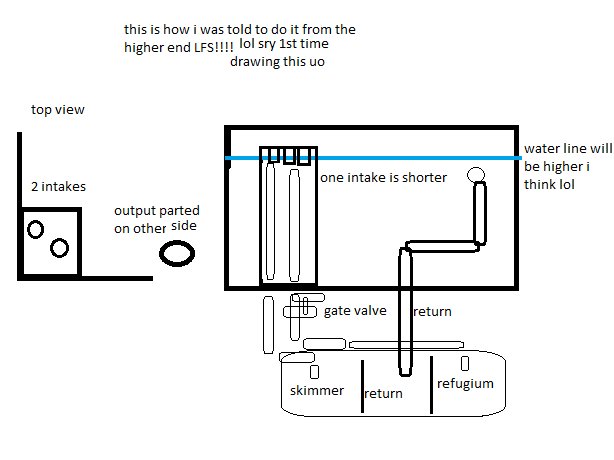

okay thxs for that but uve opened up new questions lol...

why is the intske pointing down? I was just thinkin leave it open at the top of the SP(lol) and i would get a waterfall effect and prob a lot of noise huh? Also the 2nd SP to my understanding is to silence that and the gate valve would kinda be like my valve as cranberrys was?!?!

The gate valve in your dwg will control the amount of water coming out of your lower SP, the air valve at the top of an SP controls the amount of venting (air), which actually allows the SP to work more efficiently, hence less "flushing".

Since that second lower SP has a gate valve that controls the amount of water flowing thru the SP, you should be able to run a single SP and use the gate valve to tune out the flushing. I suspect that since the taller SP won't really be working, or working very little, all you're really doing is tuning the SP that IS working for max quiet, and the taller SP is just more work.

If you want two SP's, I'd run identical duals and tune the amount of flow with a valve on your return by bleeding some of the flow back to the sump. This works because the amount of flow thru the SP's is proportional to the flow of your return pump, which is why all flow stops when you shut the pump off. The "stepped" SP's just seem like a bass-ackwards way to acomplish the same thing, since all you're doing is limiting flow thru the SP. Not saying the LFS guy's way won't work, but it's a round-about way of doing it, and if one is going to run dual SP's, why have one that either barely works or doesn't work? Finally, FWIW, two SP's means you have twice the chance of noise.

If you try it, let us know how it works...