mmstillwell01

Member

Hellow all,

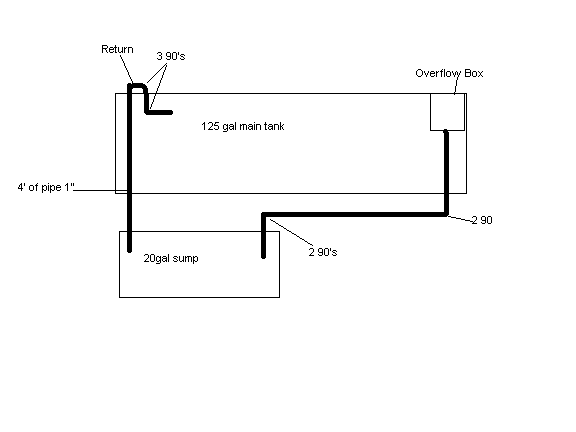

If you have an overflow box the is rated for 600gph then what size return pump would you need?

Thank you.

If you have an overflow box the is rated for 600gph then what size return pump would you need?

Thank you.