Treated or Not

- Thread starter rslinger

- Start date

rslinger

Member

5 in. on the big holes and 3 1/2 on the small. You know i am not sure....I need bulkheads on there yet...and down turned pvc yet right?? all my old tanks have been drilled on the bottom and this whole top drilled thing has me feeling lost! but i will lose tank going all the way to the bottom right? so what do you guys think the best idea is?

rslinger

Member

I have been thinking about it and yes i think that a shorter one would be better. So it would have to be about 14in across 7in deep from top to bottom and 3 1/2 wide i think.... how will i route the return through it? i would like to get the return to mid level and use a flow accelerator. I have a Mag 12 that i plan on using as the return. should give me around 1000 gallons.

acrylic51

Active Member

That's exactly what I was thinking Corey....The smaller/shorter unit would be more accommodating IMO.....I would opt for 1/8" on the back of the unit for the simple fact it will be tight against the tank glass and conserve space as well.

The return could be done with a bulkhead like the drains and you could drill the overflow box itself and put bulkheads or fittings into the overflow box to return the water. Those tank jets would actually be pretty sweet on the overflow box, which you could direct the flow.....What's your thinking??? I know Corey knows what I'm referring to when I say tank jets.

This is what's called a tank jet..This is a pic of a white 1, but I'd use black personally, but the center section is adjustable and you could direct flow easier without anything sticking into the tank......

The return could be done with a bulkhead like the drains and you could drill the overflow box itself and put bulkheads or fittings into the overflow box to return the water. Those tank jets would actually be pretty sweet on the overflow box, which you could direct the flow.....What's your thinking??? I know Corey knows what I'm referring to when I say tank jets.

This is what's called a tank jet..This is a pic of a white 1, but I'd use black personally, but the center section is adjustable and you could direct flow easier without anything sticking into the tank......

rslinger

Member

That would be nice never thought of that do the spread the flow out nice or do they direct a jet. I think the flow accelerator spreads it out more than it does anything. could i split my return in to two and use two of those tank jets. i plan on making a peninsula effect with the rock maybe one on each side? I do think the small box would be better. Do I need a down turned piece of PVC of of the bulkhead or not really? That's why i was think so deep and wide

acrylic51

Active Member

They do spread, but not a sweeping fan output.....I usually try to use my tank walls to bounce water to get flow in hard areas. I again also like seeing a tank pretty clean aestically speaking...don't like seeing wires or PH inside the tank, but at times hard to get away from. Penducators or Educators (sp) would give you a mad burst of power and they do spread out. The only negative is their size. Yes you could split the return line to 2 if you chose and run 2 tank jets.

May I ask how handy you are?

May I ask how handy you are?

rslinger

Member

I found a dremel that i can use!! Ok can i buy acrylic at like a Menards or Home Depot? Do i make a jig to cut the teeth in the overflow box or how do i go about that? Can I heat and bend it to make the bottom bend or do i have to silicone them together? Will silicone work to hold it in the tank? So many questions.

rslinger

Member

The outer holes are like 2 1/2 and the center is 1 3/8 ish. they should accept a pipe that is 1 1/2 and 3/4 i think. Do you need a special hole saw to do acrylic or not really because i have hole saws i think they are made for wood but i got a huge drill bit kit thing so maybe there is a couple for a different material.

rslinger

Member

14 in across (the holes in the tank are 11in apart so that gives me 1 1/2 on each side for bulkhead fitting should work right)

7 in deep (that gives me two in. under the bottom of the holes)

3 in. wide(gives me room for the elbows that i think i need and to run pipe for return)

I think that should work. Does it make sense to you? Do you think that maybe it needs to be 3 1/2 wide for more room for the pipes that i am running through it for the returns

7 in deep (that gives me two in. under the bottom of the holes)

3 in. wide(gives me room for the elbows that i think i need and to run pipe for return)

I think that should work. Does it make sense to you? Do you think that maybe it needs to be 3 1/2 wide for more room for the pipes that i am running through it for the returns

2quills

Well-Known Member

Quote:

Originally Posted by Rslinger http:///forum/thread/382833/treated-or-not/20#post_3348783

14 in across (the holes in the tank are 11in apart so that gives me 1 1/2 on each side for bulkhead fitting should work right)

7 in deep (that gives me two in. under the bottom of the holes)

3 in. wide(gives me room for the elbows that i think i need and to run pipe for return)

I think that should work. Does it make sense to you? Do you think that maybe it needs to be 3 1/2 wide for more room for the pipes that i am running through it for the returns

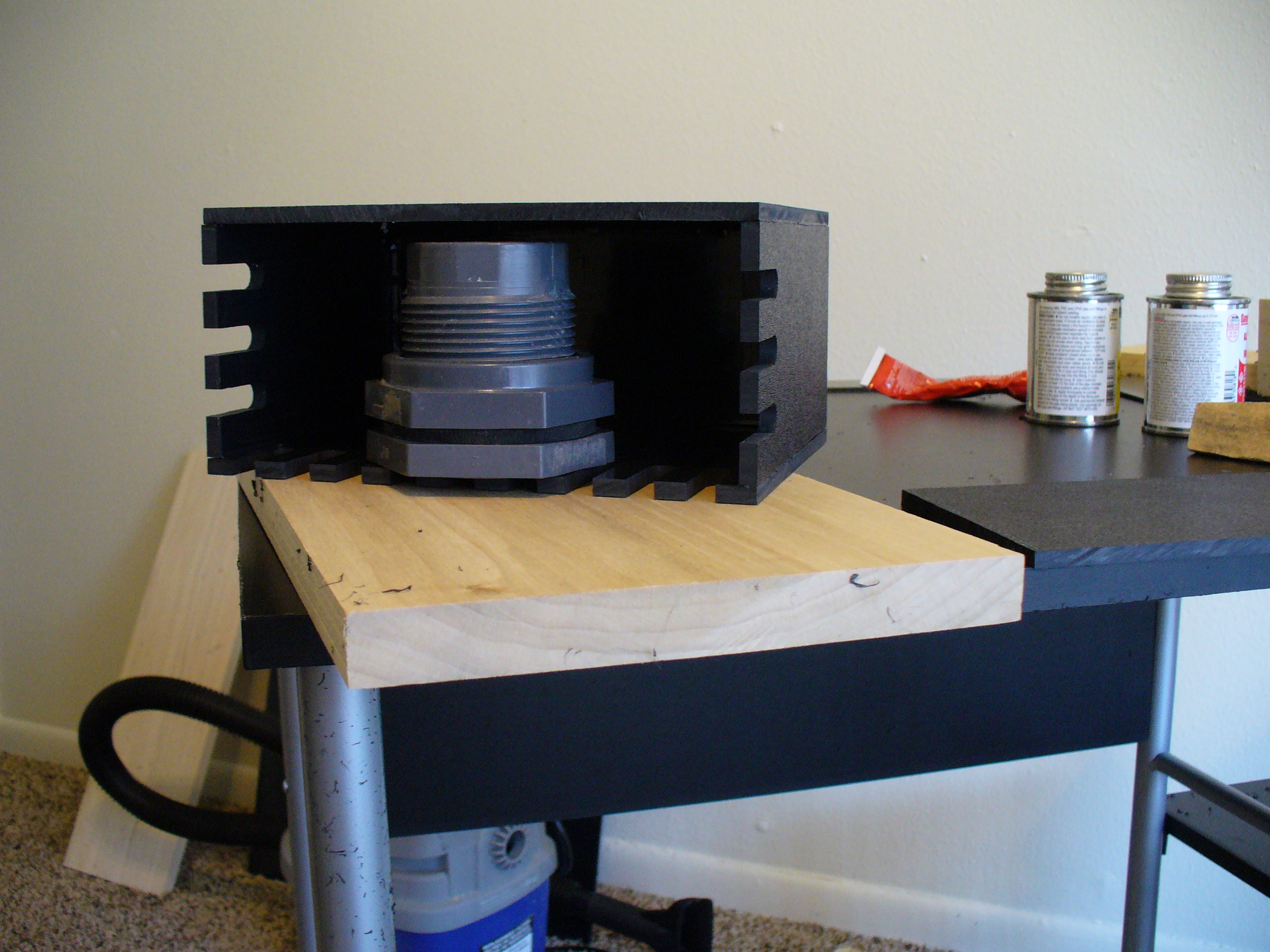

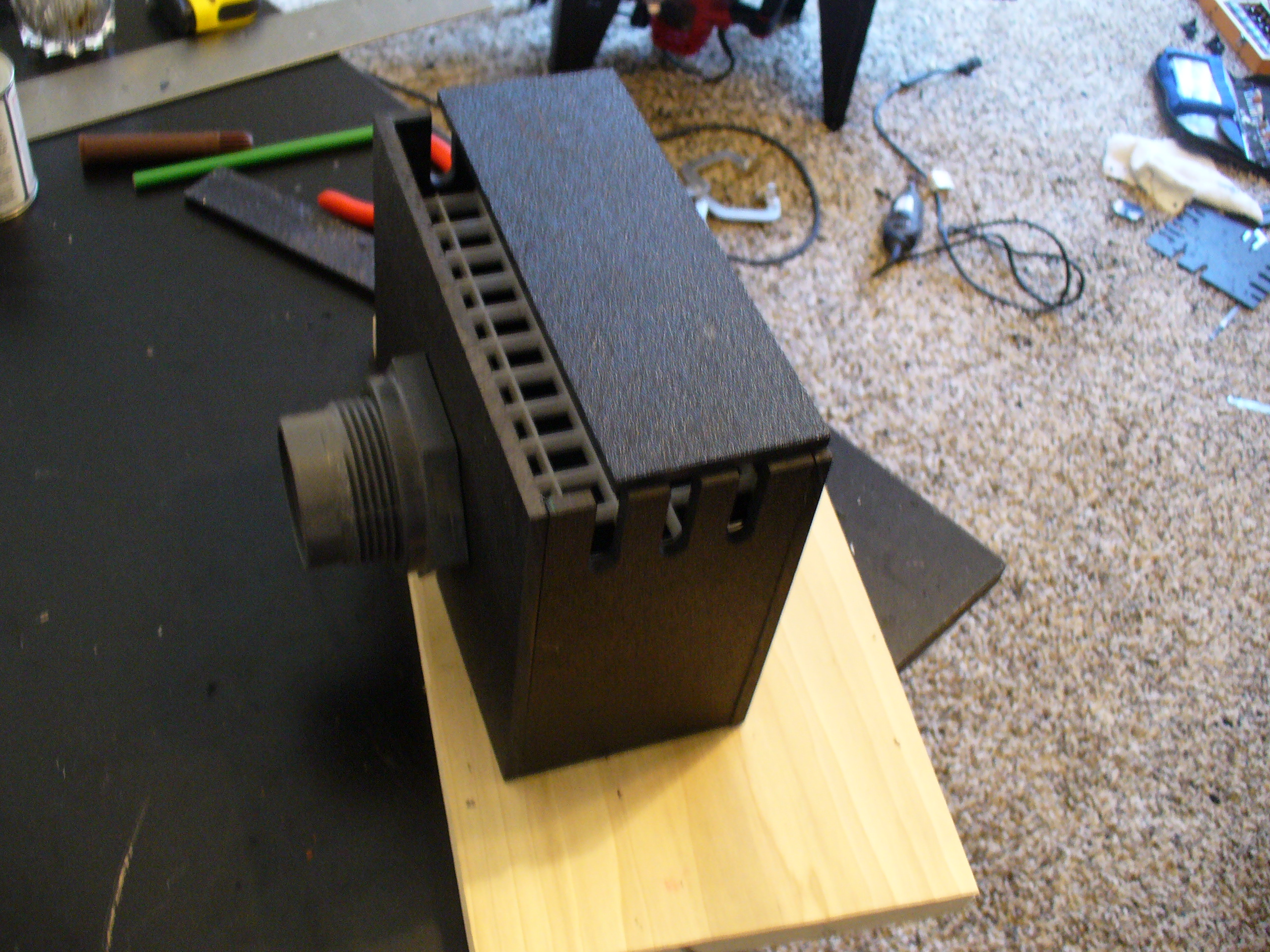

I would go just a little bit wider. Here's one I made for my 1-1/2" bulkheads. I made two of them that go on either side of the back of the tank. The overall dimensions are 8"L x 6"T x 3-3/4"W. The bulkhead in the picture is 3" long. Material thickness is 1/4". Leaves me with 3-1/4" space on the inside of the box so the bulkhead fits in and out no prob. Just to give you an idea. I haven't tried to put an elbow on the inside of it yet as I hadn't really planned on one going in there. I don't think I'd have enough room to install one with the dimensions that I used. On the backside of the the bulkheads I plan on installing a "T" and doing like a stand pipe deal on the drain outside of the tank.

Originally Posted by Rslinger http:///forum/thread/382833/treated-or-not/20#post_3348783

14 in across (the holes in the tank are 11in apart so that gives me 1 1/2 on each side for bulkhead fitting should work right)

7 in deep (that gives me two in. under the bottom of the holes)

3 in. wide(gives me room for the elbows that i think i need and to run pipe for return)

I think that should work. Does it make sense to you? Do you think that maybe it needs to be 3 1/2 wide for more room for the pipes that i am running through it for the returns

I would go just a little bit wider. Here's one I made for my 1-1/2" bulkheads. I made two of them that go on either side of the back of the tank. The overall dimensions are 8"L x 6"T x 3-3/4"W. The bulkhead in the picture is 3" long. Material thickness is 1/4". Leaves me with 3-1/4" space on the inside of the box so the bulkhead fits in and out no prob. Just to give you an idea. I haven't tried to put an elbow on the inside of it yet as I hadn't really planned on one going in there. I don't think I'd have enough room to install one with the dimensions that I used. On the backside of the the bulkheads I plan on installing a "T" and doing like a stand pipe deal on the drain outside of the tank.