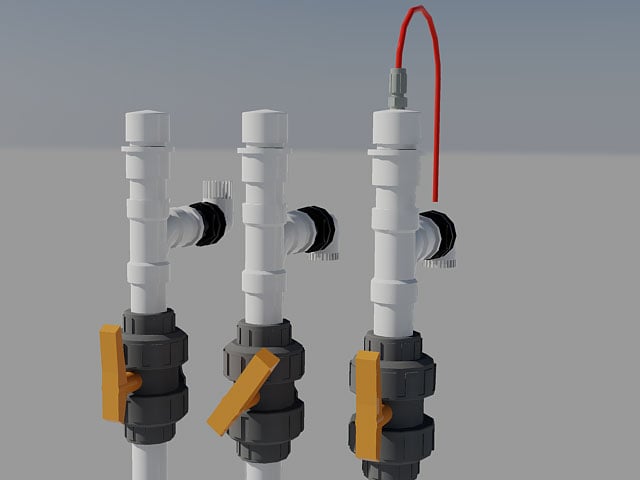

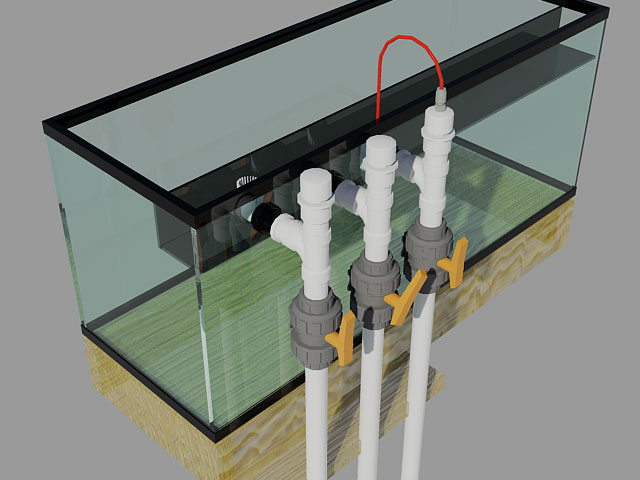

Honestly it's the same overflow I'm using on my system.....There is no exact science or plan as to the dimensions of your overflow box......The limiting factor to the design is the diameter of the bulkheads that will determine what you can flow......My overflow is basically the length of my side of my tank, and don't remember the height of the overflow box, but the height of the standpipe you have to determine.....I made some originally and ran the system, and depending how high the standpipes are in the overflow box will determine a bit of noise as well....If your standpipes are short and you have water dropping a bit of a distance it will be noisey from that portion, but you can make them a hair under the height of your teeth in your overflow if you choose, and that quiets the noise from water dropping a distance......There is so much you have to input into the layout, there isn't 1 exact size for all.....

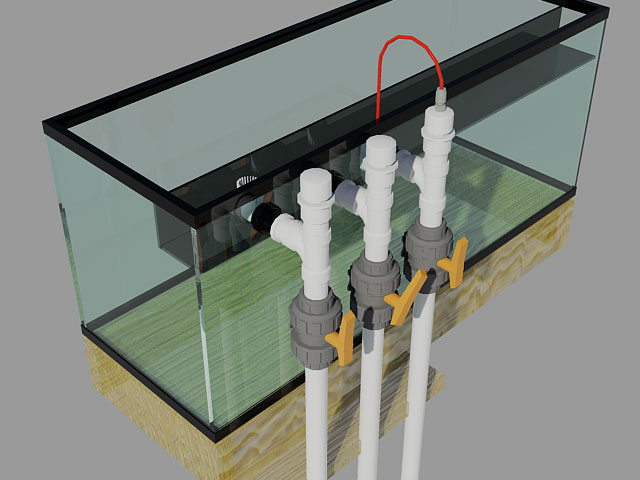

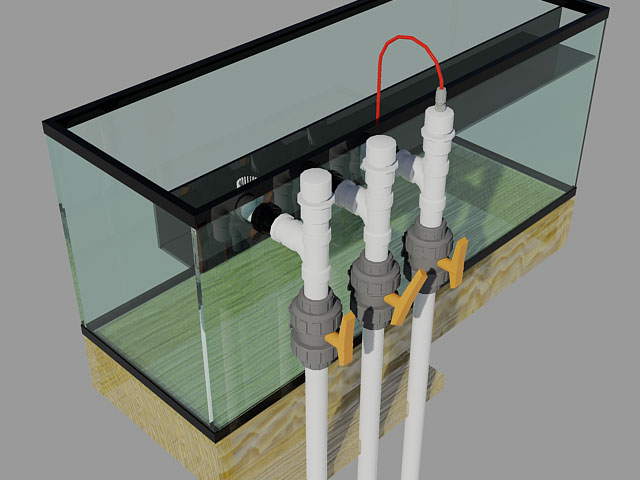

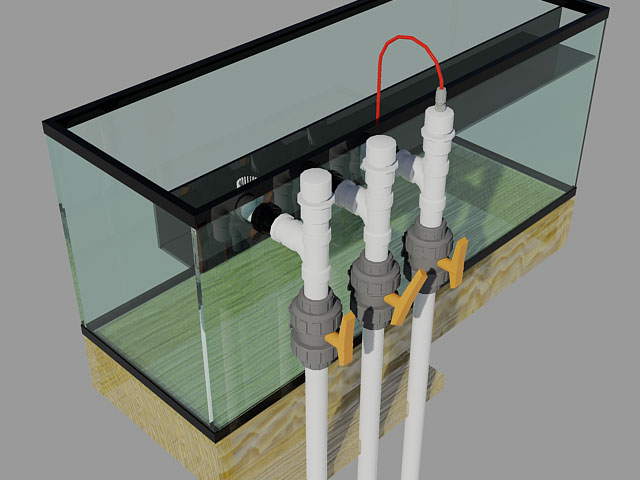

Again another pic of standpipes inside the overflow box.....I used 1 1/2" bulkheads and plumbing on my system......Again sizes are entirely up to you, but 1" would be minimum.....

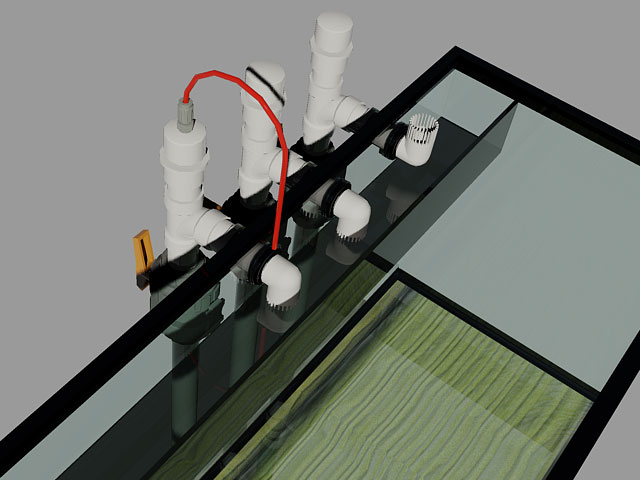

This is a shot from inside the tank looking at the teeth of the overflow box.....Those teeth are actually removable grates I fabricated when building the tank.....

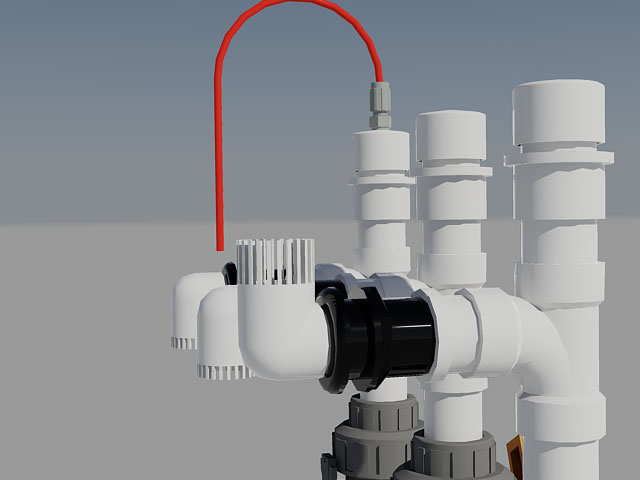

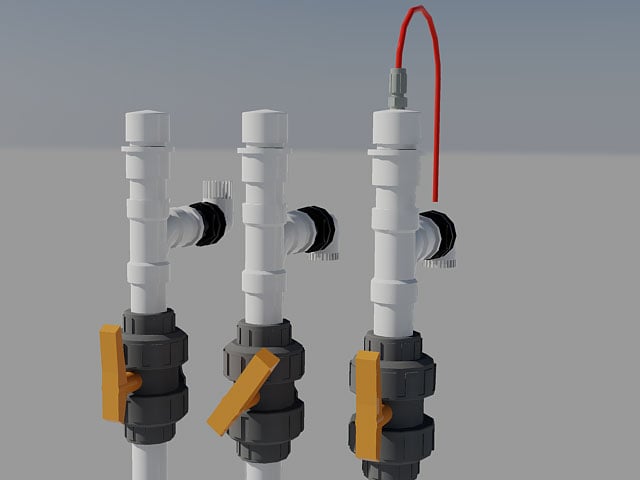

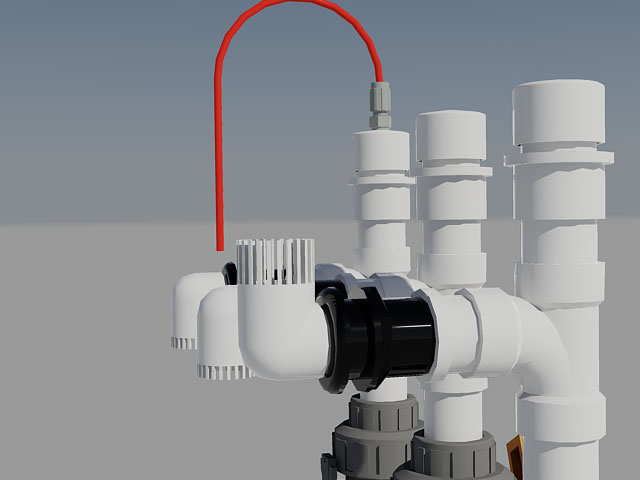

A quick pic of the valve and connection layout.....You only need 1 valve on the overflow.....That is the pipe in the middle.....The far left pipe is my emergency line incase the siphon line would clog for whatever unknown reason.....

/>

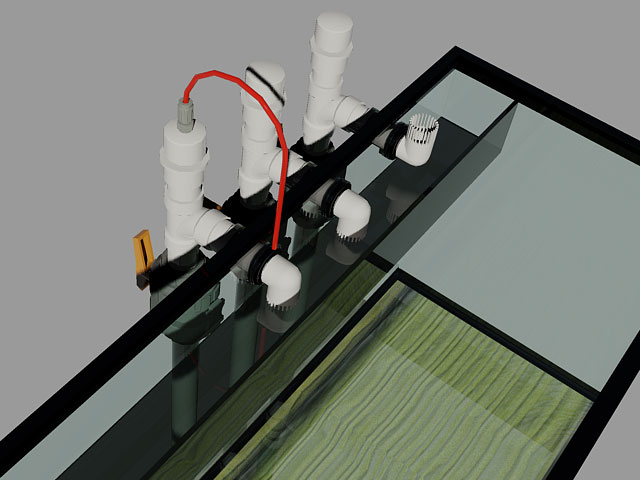

Another quick shot of my external overflow box.....You can see my standpipes aren't anything special, but they are laid out in detail in the BeanAnimal overflow thread.....but you can see the down turned elbow if that were to be raised higher it would make the water dropping from the teeth of the overflow into the overflow box less, which minimizes noise as well......

A basic pic of the inside of my overflow box.....Again my overflow box is external and is the length basically of the side of my tank.....

If you have some basic ideas of how you want to lay your overflow box out and what plans you've come up with I'm sure a few masterminds can easily help you put it together and pull it off.....What return pump have you chosen......Sump size......