dirk_brijs

Member

Whatsup all,

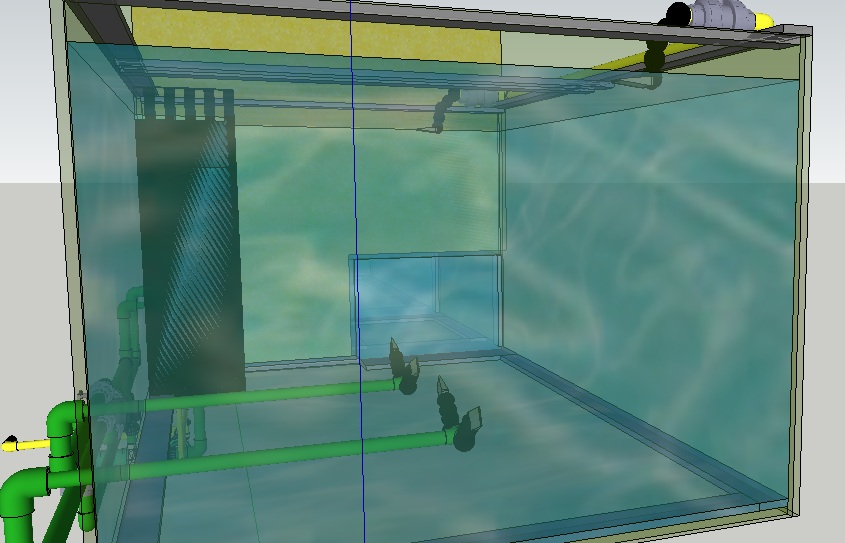

A new tank design I came up with and want to know from all of you what would be the main concerns I will have to be dealing with or elliminate before I start building the design.

I know for now no overflows etc installed in the design due to reasons before want to wait all of your advise before starting to add all those things.

Idea would be both large tanks connected with an underpass which will not be lighted at all. (reason would be flashlight fish)

Both large tanks will be stocked with mixed corals but especially softies and anemones. Lighting will be delivered by 10 AI LED modules total (5 each tank)

Anyway all advise and critices are welcome

what thickness of glass would be recommended for example? I thought 1/2" would be ok?

thanks guys.

A new tank design I came up with and want to know from all of you what would be the main concerns I will have to be dealing with or elliminate before I start building the design.

I know for now no overflows etc installed in the design due to reasons before want to wait all of your advise before starting to add all those things.

Idea would be both large tanks connected with an underpass which will not be lighted at all. (reason would be flashlight fish)

Both large tanks will be stocked with mixed corals but especially softies and anemones. Lighting will be delivered by 10 AI LED modules total (5 each tank)

Anyway all advise and critices are welcome

what thickness of glass would be recommended for example? I thought 1/2" would be ok?

thanks guys.