acrylic51

Active Member

After a break away from the hobby persuing my motocross racing, another major back surgery, addition of a new grand daughter, the bug has bitten me again, and decided to do something alittle different and a test or challenge of my skills......This build will be rather long due to time, expense and other commitments, but will try to keep it moving along.

The major goal of this tank is to have it in a major gathering point in the house and that would be in my familyroom where everyone always is, which will make it easier to maintain and notice little changes going on instead of outside my main area as my other tank consumes my 2 car garage as some might remember.

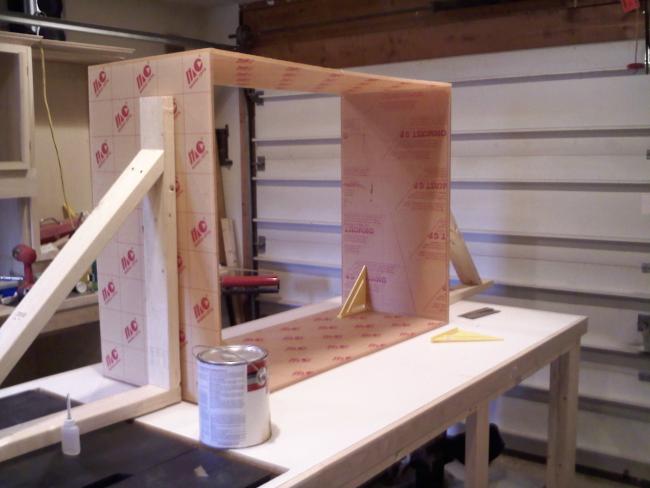

I started following a couple of threads over at -- and on Fingerlakesreef, and Bronco300 and I had talked alittle behind the scenes on the build, so alof of credit is due to Bronco300, AcroSteve(--), Dsandford(--), Kent(Fingerlakesreef). The tank will be built with plywood and epoxy resin. The tank dimensions are going to be 70"Lx48"Wx28.50"H. These are inside dimensions. The tank will be built using the pour method, but for added peace of mind, I will be incorporating 37oz biaxial fiberglass which will add to the structrual strength of the build as well. As another safety measures since a very important feature of this build will be to have no cross bracing on the 48" wide tank. Not sure if it will totally work out that way, but will see!!!!! To add in not having to add any cross bracing to the tank, the tank will be eurobrace 6" the entire way around the perimeter of the tank and there will b a steel frame 2" angle iron built around the intial plywood box, that will be embedded in epoxy that will be modified with West High Strength additive. One reason for all the reinforcement is that I'm plannng on haveing an external wavebox housing 3-4 Tunze 6101s or 6205's. Another important reason is the tank will feature an external overflow box on the back of the tank that will be 48"Lx12"Wx12"H. Getting alittle ahead of myself I will be using West Epoxy, and there are other epoxies such as MAS, US Composites, etc........The steel framing will be totally hidden from sight by covering the steel with a skin of finished wood.

Again the new tank will be housed in my familyroom, and since I have a full bath off the familyroom and walk in closet as well, I figured why not put that wasted space of the full bath and walk-in closet to use......Sorry guys!!!!! I have 3 full baths upstairs in the house, so no not giving up to much

So the build will be alittle slow, because I have to do alittle deconstruction work on the bathroom and walk in closet and alittle framing and drywall work, and I will have to come up with a duct system to the outside of the house to vent the humidity from the fish room as well. Another challenge of this build is my main water lines are running over top of were the tank will sit, and I have plans to reroute those lines and water filter in the build process, which should make my wife and daughters extremely happy shutting off the water during this process. There are still alot of parts that haven't come together and this is where I'm going to get you guys involved and need opinions and advice in areas......

So the build will be alittle slow, because I have to do alittle deconstruction work on the bathroom and walk in closet and alittle framing and drywall work, and I will have to come up with a duct system to the outside of the house to vent the humidity from the fish room as well. Another challenge of this build is my main water lines are running over top of were the tank will sit, and I have plans to reroute those lines and water filter in the build process, which should make my wife and daughters extremely happy shutting off the water during this process. There are still alot of parts that haven't come together and this is where I'm going to get you guys involved and need opinions and advice in areas......

1. For exhausting and controlling humidity in the fishroom would you opt for an exhaust fan type setup or considering controlling humidity by air conditioning the room?

2. Anyone have any good ideas or designs on how to build a structurally sound multi-function quarantine tank stand, and work table area within the fishroom? I'm considering welding a steel frame and making the traditional rectangular shape like a typical stand, but wanting to angle the front legs back towards the wall and use the wall actually as support for the stand/table? Would this work?

So again guys....give me some feedback and will get the build rolling!!!!!!!!!

The major goal of this tank is to have it in a major gathering point in the house and that would be in my familyroom where everyone always is, which will make it easier to maintain and notice little changes going on instead of outside my main area as my other tank consumes my 2 car garage as some might remember.

I started following a couple of threads over at -- and on Fingerlakesreef, and Bronco300 and I had talked alittle behind the scenes on the build, so alof of credit is due to Bronco300, AcroSteve(--), Dsandford(--), Kent(Fingerlakesreef). The tank will be built with plywood and epoxy resin. The tank dimensions are going to be 70"Lx48"Wx28.50"H. These are inside dimensions. The tank will be built using the pour method, but for added peace of mind, I will be incorporating 37oz biaxial fiberglass which will add to the structrual strength of the build as well. As another safety measures since a very important feature of this build will be to have no cross bracing on the 48" wide tank. Not sure if it will totally work out that way, but will see!!!!! To add in not having to add any cross bracing to the tank, the tank will be eurobrace 6" the entire way around the perimeter of the tank and there will b a steel frame 2" angle iron built around the intial plywood box, that will be embedded in epoxy that will be modified with West High Strength additive. One reason for all the reinforcement is that I'm plannng on haveing an external wavebox housing 3-4 Tunze 6101s or 6205's. Another important reason is the tank will feature an external overflow box on the back of the tank that will be 48"Lx12"Wx12"H. Getting alittle ahead of myself I will be using West Epoxy, and there are other epoxies such as MAS, US Composites, etc........The steel framing will be totally hidden from sight by covering the steel with a skin of finished wood.

Again the new tank will be housed in my familyroom, and since I have a full bath off the familyroom and walk in closet as well, I figured why not put that wasted space of the full bath and walk-in closet to use......Sorry guys!!!!! I have 3 full baths upstairs in the house, so no not giving up to much

1. For exhausting and controlling humidity in the fishroom would you opt for an exhaust fan type setup or considering controlling humidity by air conditioning the room?

2. Anyone have any good ideas or designs on how to build a structurally sound multi-function quarantine tank stand, and work table area within the fishroom? I'm considering welding a steel frame and making the traditional rectangular shape like a typical stand, but wanting to angle the front legs back towards the wall and use the wall actually as support for the stand/table? Would this work?

So again guys....give me some feedback and will get the build rolling!!!!!!!!!