phixer.

New Member

Mostly because of anti racking probably, thats the weakness Ive seen with some of the other I beam / H beam stands. Ive got to assemble the stand on site so would not be able to fit a 10ft welded steel stand down the stairs. Have drawn up plans one made of square steel tubing though but decided against it. Could do it in sections but then each section would have to be leveled and bolted together. Too much of a hassle.

Four W6X25 beams resting on two 16 x 16" concrete filled, rebar re-enforced walls 3ft tall and supported in the center by a 8x16" wall should provide enough anti racking stability. Front to back support comes from the beams being bolted into threaded hooked rods cast into the concrete that fills the cinderblocks.

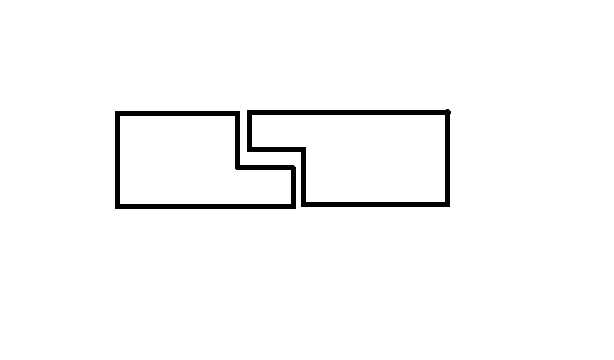

Kind of like this except the one I have in mind will have (2) 10ft beams, (2) 9ft beams (2) 3ft beams to span the end gaps. The beams and the walls will be larger and wider than those in the photo and will include a center wall. Will also have the 3ft H beams on the ends. What do you think of this idea?

but

but

Four W6X25 beams resting on two 16 x 16" concrete filled, rebar re-enforced walls 3ft tall and supported in the center by a 8x16" wall should provide enough anti racking stability. Front to back support comes from the beams being bolted into threaded hooked rods cast into the concrete that fills the cinderblocks.

Kind of like this except the one I have in mind will have (2) 10ft beams, (2) 9ft beams (2) 3ft beams to span the end gaps. The beams and the walls will be larger and wider than those in the photo and will include a center wall. Will also have the 3ft H beams on the ends. What do you think of this idea?