snakeblitz33

Well-Known Member

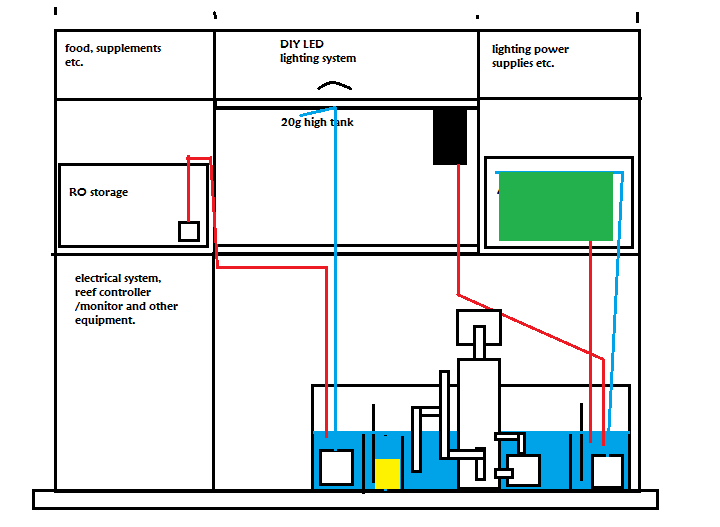

So, after looking at my POS aquarium stand, I decided to go ahead and build a custom stand for my tank, since I'm going to keep the same size tank until I get out of college again at least - I figured I would go all out and do it right.

Here's what I want to happen:

I'm keeping the 20g high tank for the display tank and an empty 20g long tank as a sump. I'm going to take the 10g sump I have now and convert it into a contained ATS that will sit beside or above the 20g. I'm not exactly sure how I want to do everything just yet.

Dimensions:

20g high: 24x12x16

20g long: 30x12x12

10g: 20x10x12

Possible 5 1/2g: 16x8x10 (ro resivoir)

I could get two 5 1/2g tanks. One, I could use for the RO resivoir and the other I can use for the ATS. I would like to use my 10g I have now for something, but I don't see it happening in the space that I have. If someone has a very creative solution, I'm all for it!

I'll post some diagrams of my thoughts later this evening.

Here's what I want to happen:

I'm keeping the 20g high tank for the display tank and an empty 20g long tank as a sump. I'm going to take the 10g sump I have now and convert it into a contained ATS that will sit beside or above the 20g. I'm not exactly sure how I want to do everything just yet.

Dimensions:

20g high: 24x12x16

20g long: 30x12x12

10g: 20x10x12

Possible 5 1/2g: 16x8x10 (ro resivoir)

I could get two 5 1/2g tanks. One, I could use for the RO resivoir and the other I can use for the ATS. I would like to use my 10g I have now for something, but I don't see it happening in the space that I have. If someone has a very creative solution, I'm all for it!

I'll post some diagrams of my thoughts later this evening.