Quote:

Originally Posted by

1Snapple http:///t/378912/2quills-120g-re-build-thread/620#post_3448999

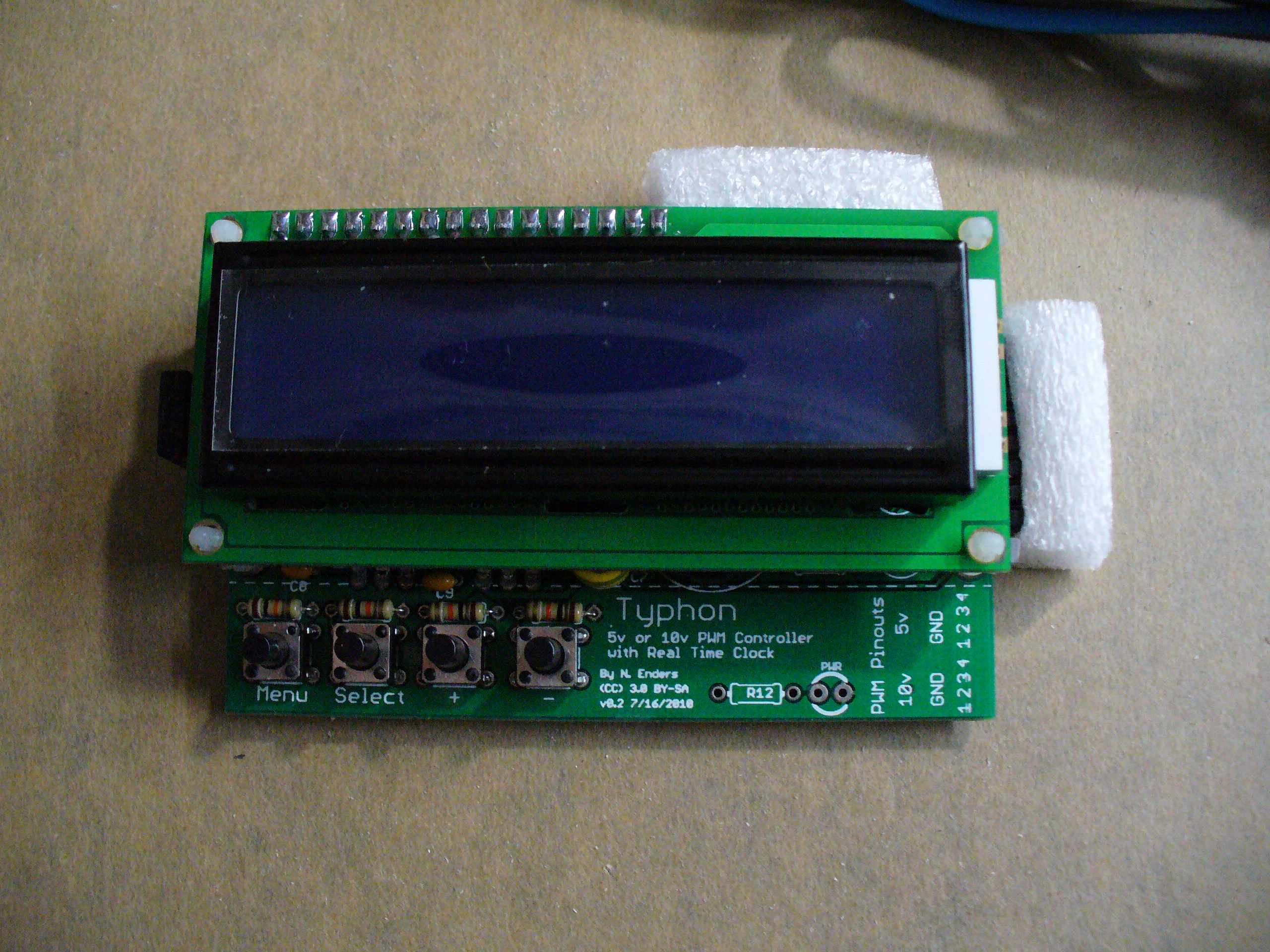

Why not the XMLs? And i will have to check out that Typhoon, Does it run both of the drivers? and is on timers also?

It is a timer. It has 4 channels so I can control upto 4 channels independentaly. Set sunrise time and duration time for how long it takes for the drivers to ramp up current over a long or short course of time. Same with ramp down time. Set each channel what you want.

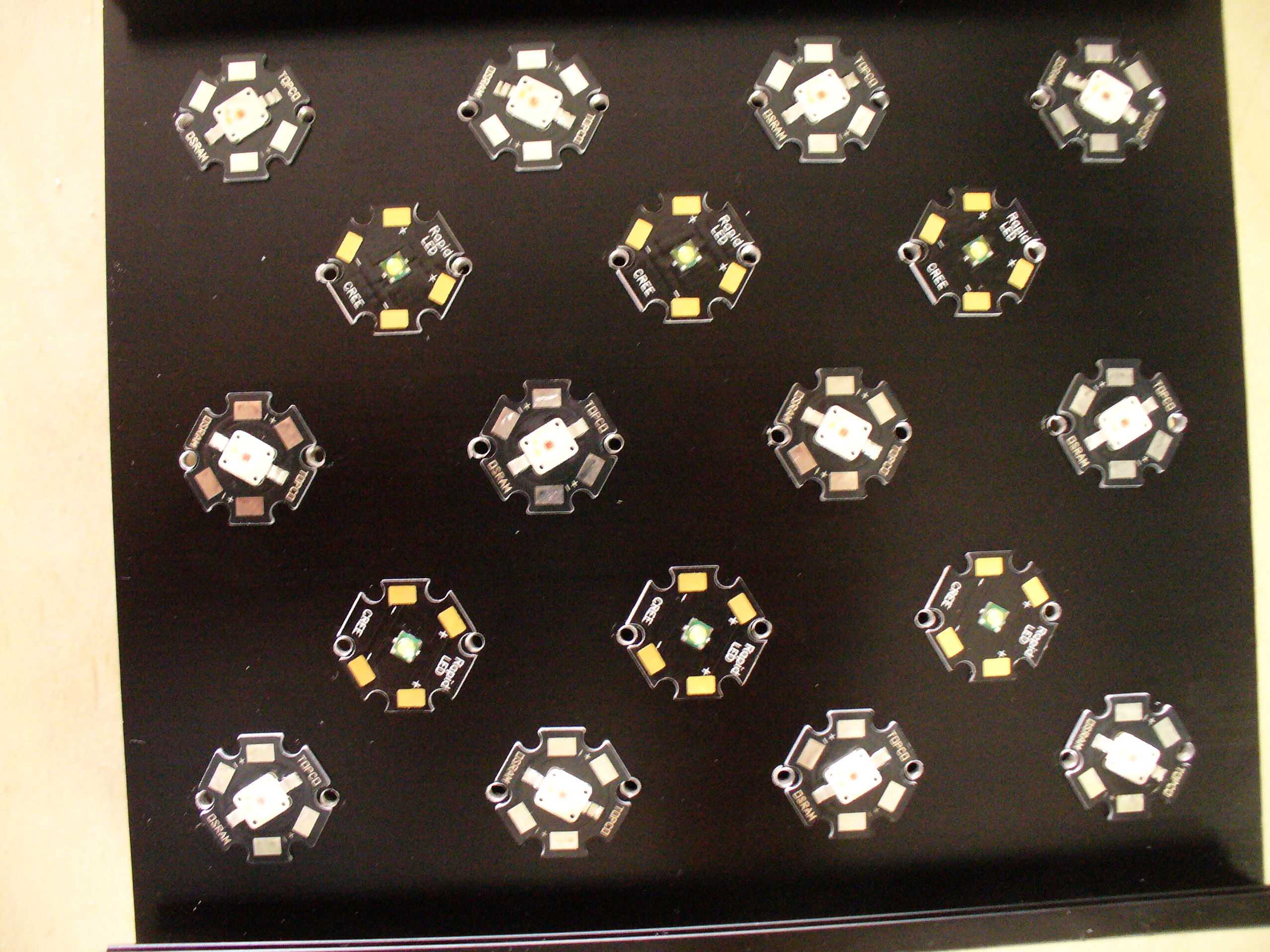

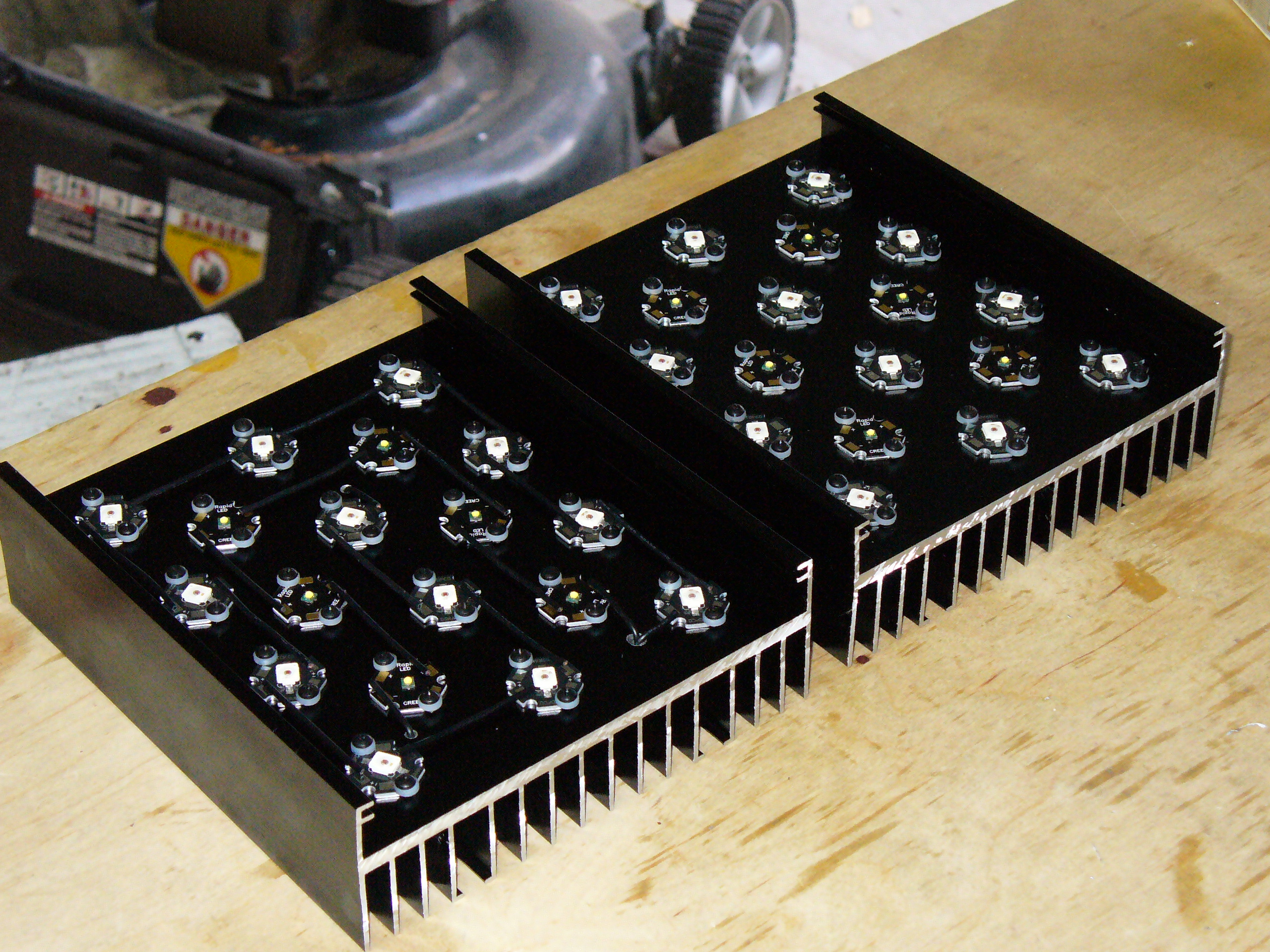

Why not XML's? Because I don't have a need for anything that heavy in cool white. Neutral and Warm you have to order from out of the country. A lot of places are advertising them as the most efficient, and they can be. But the only bin that they produce that is more efficient than XPG R5 the the XML U2'S. Places here are only selling XML T6's. And if you crunch the numbers those T6's are actually slightly less efficient than XPG R5. So with the extra cost of the XML's it becomes a wash. The only benefit I see to having them is if you have a very deep tank with some heavy lighting requirements at the sand bed, then you can drive them at much higher current and get more light out of em.

I won't have that need. XPG is cheaper to replace and more than enough light than I'll really ever need. The differences in efficiency when you compare the best is really rather small and hardly worth a mention. Either of these lights can fry some coral real quick.