Quote:

Originally Posted by

SnakeBlitz33 http:///t/376802/415-gallon-plywood-tank-build/1320#post_3449334

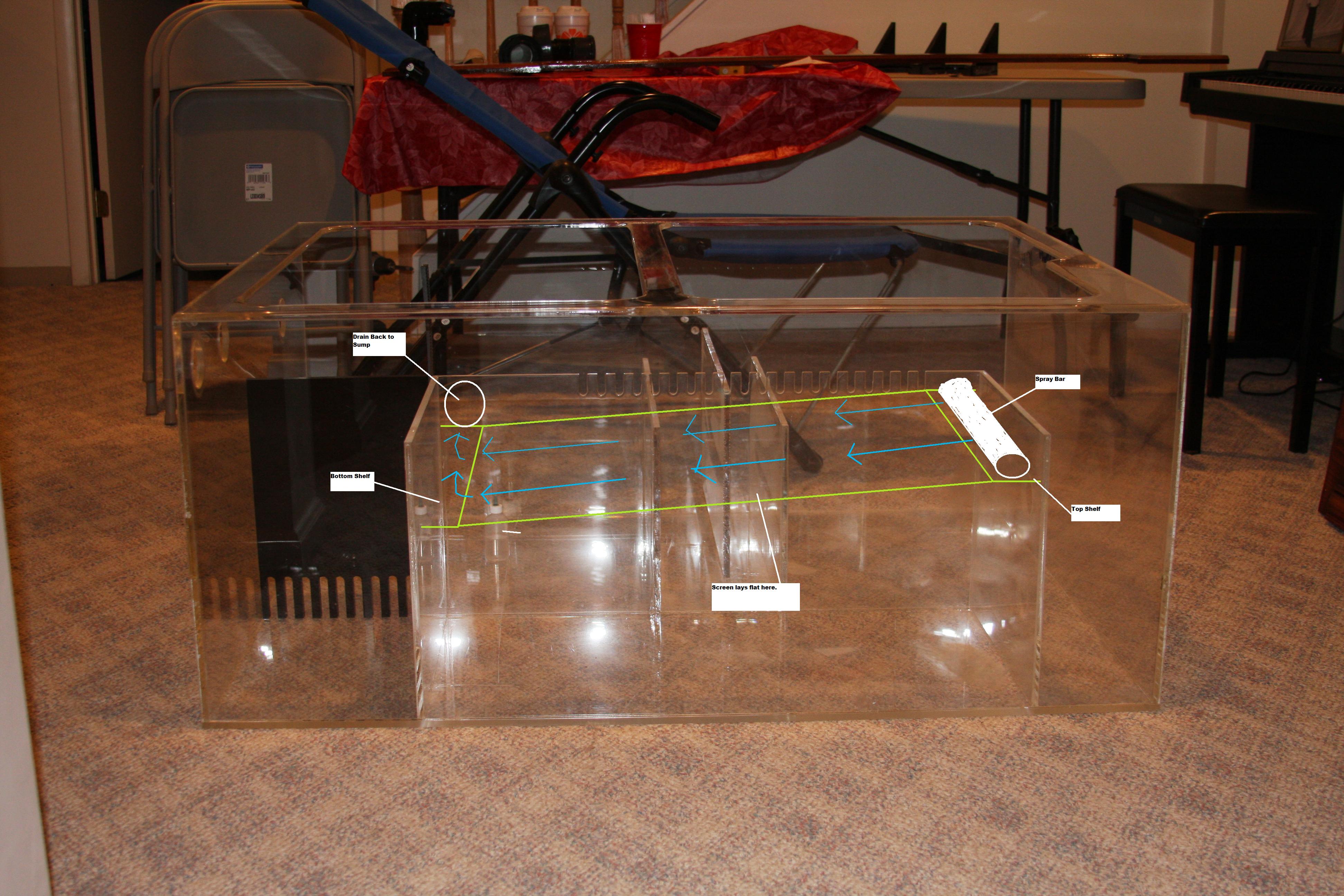

The return pump baffle chamber that keeps the water level high in the scrubber section (the middle baffle) was way too high. I thought that I would put the end of the scrubber screen level with the water, but I didn't account for the water level rising a little once the return pump was turned on and a quarter of the screen was constantly submerged. So, that wouldn't have worked well. If the water was allowed to drop off of the screen into the water, it would have worked much better. Another problem I incurred was that it was difficult to attach the screen to anything to get even water flow across it. I'm sure one of you could figure something out but I got impatient. I'll return to this design one day and perfect it, but I didn't have time to do it since my tank was running on just powerheads at the time I re-built this sump!

lol, wow you are patient! Thank you for waiting... I didn't know my opinion was valued so much. lol

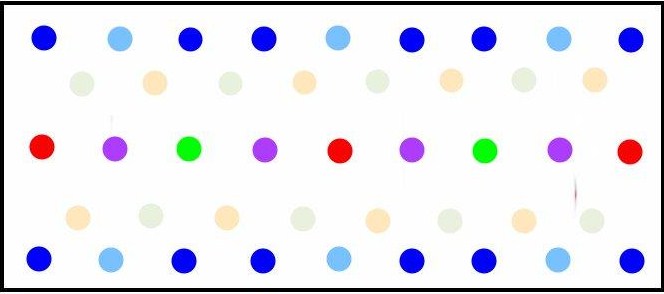

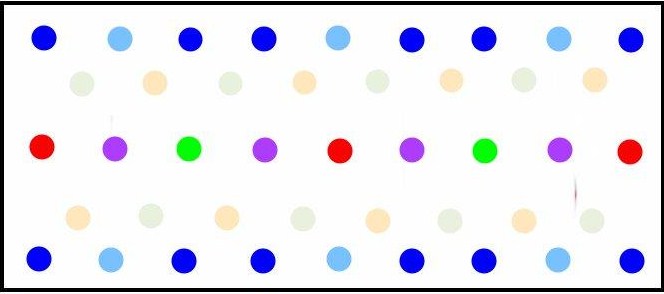

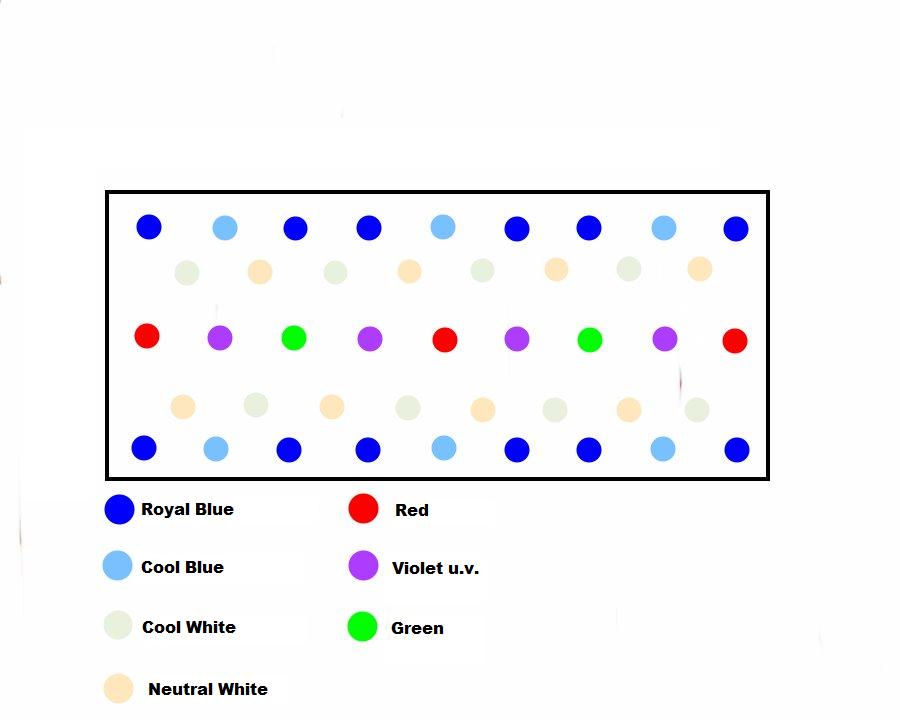

I personally think that a horizontal algae scrubber would be pretty awesome, especially in those dimensions. You will have to cut a piece of acrylic out the same size as the scrubber to keep water from splashing over the sides. It's also better to not glue in the acrylic, and have it fully removable so that you can add or take away live rock, sand and anything else you want to keep under the screen. The only real problem that I had with it was that water was not allowed to completely run off the bottom of the screen. If it did, I probably would have used that design. Keep in mind that you have to have 2x the flow and 4x the amount of light for it to work to it's full potential. I would really like to see a horizontal scrubber on your tank. Of course, you know it won't be big enough to handle the entire bioload of the tank, but you're not really concerned about that.

1. design it where the water will fully run off the screen.

2. Attach the screen to the pipe or something somehow to keep the screen from sliding off the acrylic.

3. 2x the flow and 4x the light and it should grow perfectly.

4. The screen in Corey's design needs to slope from left to right, and the hole drilled needs to be in the middle or preferably under the end of the screen to let water drain completely off the bottom of the screen.

I hope this gave you some good ideas. If I can find the original pic of that sump, I'll draw you up a little diagram like Corey did.

Looking forward to seeing the design.....Waiting patiently!!!!!!!