415 Gallon Plywood Tank Build

- Thread starter acrylic51

- Start date

gemmy

Active Member

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455543

Thanks for the info Shawn, yes I am here for business. Someone told me Lancaster, PA is an hour from here. I got to a couple real good LFS here bought some cheap filter socks and some DT's phyto feed.

Are you able to get aquavitro around you in Canada? There is a pet store near Langhorne that has it for sale.

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455543

Thanks for the info Shawn, yes I am here for business. Someone told me Lancaster, PA is an hour from here. I got to a couple real good LFS here bought some cheap filter socks and some DT's phyto feed.

Are you able to get aquavitro around you in Canada? There is a pet store near Langhorne that has it for sale.

al&burke

Active Member

Quote:

Originally Posted by Gemmy http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455547

Are you able to get aquavitro around you in Canada? There is a pet store near Langhorne that has it for sale.

Yes I can get it in Canada - thanks Krista for thinking of that though. I should have checked it out for pricing though. I come here at least once a year, I will PM you next time.

Originally Posted by Gemmy http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455547

Are you able to get aquavitro around you in Canada? There is a pet store near Langhorne that has it for sale.

Yes I can get it in Canada - thanks Krista for thinking of that though. I should have checked it out for pricing though. I come here at least once a year, I will PM you next time.

acrylic51

Active Member

Not sure how far Lancaster is from Langhorne Al.....Lancaster is about 40 minutes from me, but Langhorne is over Philly way between Philly and Jersey.....What store in Langhorne carries Aquavitro......Honestly with the salt being so hard to come by not sure if it's really worth the effort.......

gemmy

Active Member

Quote:

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455594

Not sure how far Lancaster is from Langhorne Al.....Lancaster is about 40 minutes from me, but Langhorne is over Philly way between Philly and Jersey.....What store in Langhorne carries Aquavitro......Honestly with the salt being so hard to come by not sure if it's really worth the effort.......

It's the Hidden Reef in Levittown. It is only about an hour from me, but I am never out that way. I am going to try the H2Ocean salt.

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1400#post_3455594

Not sure how far Lancaster is from Langhorne Al.....Lancaster is about 40 minutes from me, but Langhorne is over Philly way between Philly and Jersey.....What store in Langhorne carries Aquavitro......Honestly with the salt being so hard to come by not sure if it's really worth the effort.......

It's the Hidden Reef in Levittown. It is only about an hour from me, but I am never out that way. I am going to try the H2Ocean salt.

acrylic51

Active Member

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1380#post_3455537

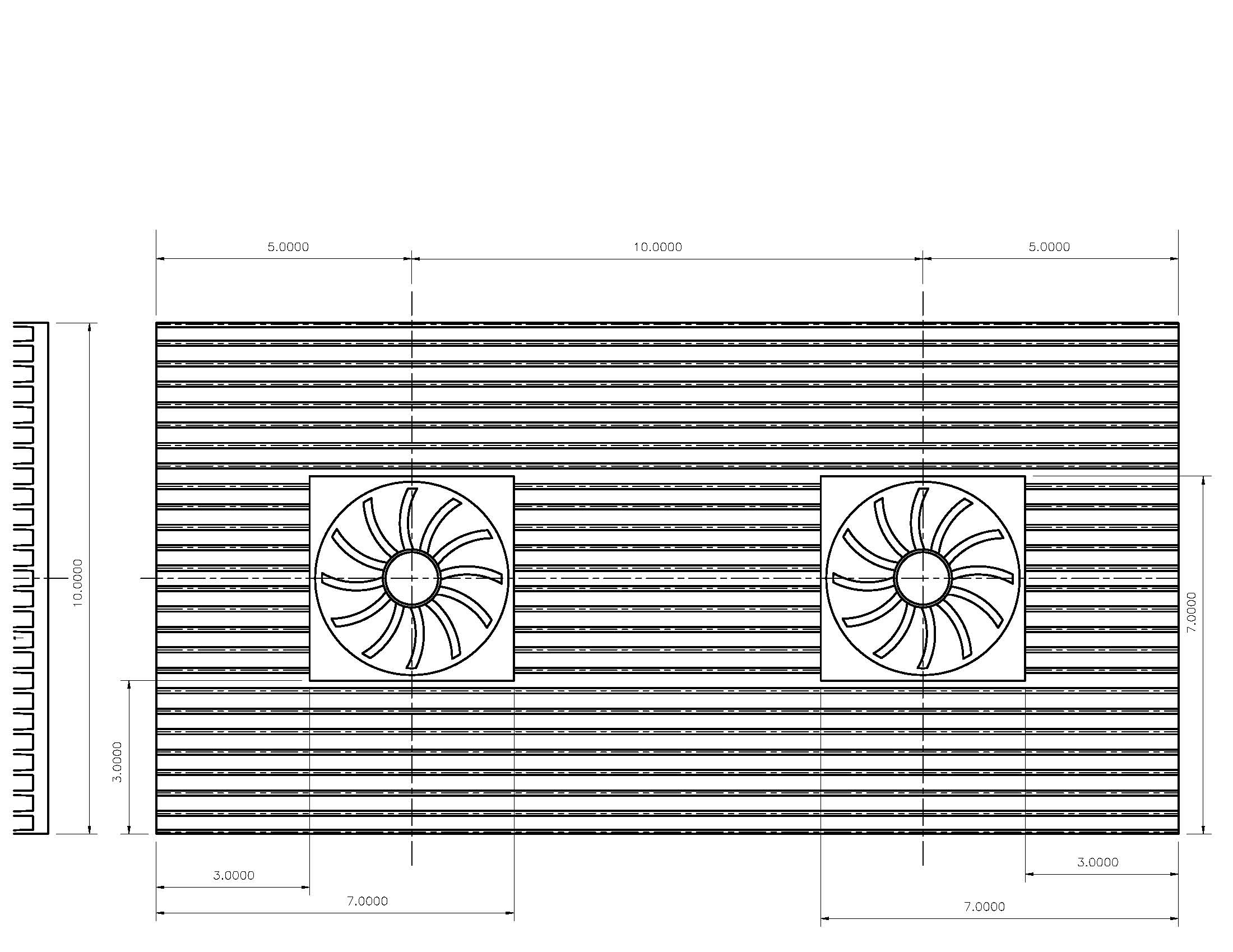

Send me the dimensions for your lights Shawn, hey I am in Langhorne, PA is that anywhere close to you. I hope not because I am going home early tomorrow morning and I can't stop. Looking forward to that info buddy.

Hey Al sent you the PM with the info for the drawings......

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1380#post_3455537

Send me the dimensions for your lights Shawn, hey I am in Langhorne, PA is that anywhere close to you. I hope not because I am going home early tomorrow morning and I can't stop. Looking forward to that info buddy.

Hey Al sent you the PM with the info for the drawings......

acrylic51

Active Member

I'm pretty sure I've seen that at my local place.....I've been looking and considering ESV B-ionic for my salt.....It's getting closer and closer to that time......I still have to finish up a small run of plumbing coming off my gfo/carbon reactors and I can bring that line online, and adjust the flow accordingly at the return pump and overflow.....I'm actually getting pretty good at tuning the overflow box. I have learned if you make an adjustment at the return pump you have to adjust accordingly at the overflow box, but I must say that once you have the pump and overflow box set, you can forget about having to tune it again.....I constantly turn everything off to double check siphon breaks and such, but check to make sure the overflow adjusts and settles out as it should.....

Honestly anyone building or designing a system seriously needs to check out the BeanAnimal overflow design.....Very simple to build, easy to tune; and once you tune it forget about it!!!!!!!

Honestly anyone building or designing a system seriously needs to check out the BeanAnimal overflow design.....Very simple to build, easy to tune; and once you tune it forget about it!!!!!!!

southern wolf

Member

Quote:

Originally Posted by 2Quills http:///t/376802/415-gallon-plywood-tank-build/1340#post_3452919

Corey... where did you find these?

Originally Posted by 2Quills http:///t/376802/415-gallon-plywood-tank-build/1340#post_3452919

Corey... where did you find these?

snakeblitz33

Well-Known Member

Quote:

Originally Posted by Southern Wolf http:///t/376802/415-gallon-plywood-tank-build/1400#post_3458043

Corey... where did you find these?

I'm not Corey, but you can get those GFCI's at the evil big box store named Walmart for around $15. I'm sure Home Depot sells them for about the same price. Not sure if they are American made or not.

Originally Posted by Southern Wolf http:///t/376802/415-gallon-plywood-tank-build/1400#post_3458043

Corey... where did you find these?

I'm not Corey, but you can get those GFCI's at the evil big box store named Walmart for around $15. I'm sure Home Depot sells them for about the same price. Not sure if they are American made or not.

southern wolf

Member

Nothing is American made anymore... but that's a whole nother topic.

snakeblitz33

Well-Known Member

Since you all are talking about the beananimal design all the time, I guess I will try one on my 90g upgrade.  Could you though pm me some information about the coast to coast thing you were talking about in another thread? I'm interested.

Could you though pm me some information about the coast to coast thing you were talking about in another thread? I'm interested.

acrylic51

Active Member

Here you go Seth.....

Silent and Failsafe Overflow System

[hr]

In the process of building my 75G in-wall setup I was posed with a problem. The tank is adjacent to my home theater and home office. The equipment room (behind the tank) is a small room attached to my home office. It was very important to setup a system that was as quiet as possible.

I fiddled with Dursos and Stockmans for weeks. The tank was plumbed with (3) 1" bulkheads and a Calfo style overflow. It quickly became apparent that the popular Stockman/Durso style setups were an improvement over an open standpipe but they left a lot to be desired. Setting them was finicky at best. I incorporated an air valve to fine tune the standpipes but was frustrated by the fact that they had to be constantly adjusted. I was also not happy with the massive amount of air that was being sucked into the sump.

I used 1" bulkheads, but the system can be scaled-up (or down) to fit any size tank and plumbing. The principle of operation does not change.

The design criteria:

1) Dead Silent

2) Set and Forget

3) Limit Bubbles in Sump

4) Failsafe to Prevent Floods

5) Easy to Clean if Needed

So I came up with a better plan:

From left to right:

1) Emergency standpipe

2) Siphon standpipe

3) Open channel standpipe

All of the standpipes are built with 1.5" PVC fittings (adapted to the 1" bulkhead with a bushing). Each standpipe consists of a Sanitary-Tee topped with a threaded adaptor and a screw on cap. True union ball valves below the Tee are for adjustment of the system and/or isolation of the display if needed. The valve is only truly needed on the Siphon (middle) standpipe. The Open Channel standpipe (right) is fitted with an airline that is curled back over and attached just below the trim inside the overflow box. All caps are sealed with teflon tape so that they are airtight.

Something to keep in mind:

A submerged drain that is running at a full siphon will handle MUCH MORE flow than a similar drain that allows air in.

How the system works:

Notice that both the Emergency (left) and Siphon (middle) standpipes are capped. During normal operation the valve on the Siphon (middle) standpipe is adjusted (as shown in the render above) until the water level in the overflow box rises high enough that air is not being sucked into its down-turned elbow. This means that the standpipe is running at full siphon with NO air being sucked in. This is DEAD SILENT. However, it also means that the standpipe is NOT handling all of the flow from the return pump. This is where the Open Channel (right) standpipe comes into play. The Open Channel (right) standpipe is open to the air via the airline attached to it. Because air is allowed in, the standpipe will not siphon or gurgle. The excess flow that is not being handled by the Siphon (middle) standpipe quetly flows through the Open Channel (right) standpipe. Because the flow is very low, very little air makes its way to the sump.

This setup is VERY set-and-forget! It is self tuning over a very wide range and does not need to be touched once set. It operates silently and introduces very little air into the sump (if any). The caps can be removed to clean the standpipes if the situation ever arises.

Failsafe:

The setup has (2) failsafe features.

1) The Emergency (left) standpipe is set at a level slightly higher than the normal operating height of the overflow box. It is simply an up-turned elbow or strainer. If the water level rises above the normal operating level then it will flow down the Emergency (left) standpipe. This standpipe is also airtight. If the water level rises high enough the standpipe will begin to siphon and flush the overflow box.

NOTE:The Emergency (left) standpipe will also kick in during system startup. It takes a few moments for the air to be purged from the Siphon (middle) standpipe, during which time the water level in the overflow box may run high and into the Emergency (left) standpipe.

2) The Open Channel (right) standpipe is equipped with an airline that is attached in the overflow box. If the water level rises to the critical point of overflow and the Emergency (left) standpipe can not handle the flow (say due to blockage from algea or something) then the water will cover the inlet of the airline. The flooded air intake will in effect convert the Open Channel (right) standpipe into a full siphon standpipe, allowing it to handle much more flow. This will flush the overflow box and prevent flooding.

That's it... simple and effective!

This system MUST use the (3) standpipes that are described above. The emergency standpipe is a CRITICAL part of this design. Omitting the emergency standpipe is asking for a flood!

Here are some other renderings that show some of the detail. I prefer to have the strainers touch the bottom of the overflow box. I used a table saw to fabricate them out of street elbows. No snails or fish can get into the standpipes. If your overflow box is deeper, then standard bulkhead strainers or those from a place aquaticeco can be used.

The CAP on the Open Channel standpipe was drilled, tapped and then threaded to accept a standard John Guest airline fitting.

All (3) standpipes extend into the sump and terminate just below the water level.

[hr]

Last edited by BeanAnimal; 02/03/2008 at 02:49 PM.

Silent and Failsafe Overflow System

[hr]

In the process of building my 75G in-wall setup I was posed with a problem. The tank is adjacent to my home theater and home office. The equipment room (behind the tank) is a small room attached to my home office. It was very important to setup a system that was as quiet as possible.

I fiddled with Dursos and Stockmans for weeks. The tank was plumbed with (3) 1" bulkheads and a Calfo style overflow. It quickly became apparent that the popular Stockman/Durso style setups were an improvement over an open standpipe but they left a lot to be desired. Setting them was finicky at best. I incorporated an air valve to fine tune the standpipes but was frustrated by the fact that they had to be constantly adjusted. I was also not happy with the massive amount of air that was being sucked into the sump.

I used 1" bulkheads, but the system can be scaled-up (or down) to fit any size tank and plumbing. The principle of operation does not change.

The design criteria:

1) Dead Silent

2) Set and Forget

3) Limit Bubbles in Sump

4) Failsafe to Prevent Floods

5) Easy to Clean if Needed

So I came up with a better plan:

From left to right:

1) Emergency standpipe

2) Siphon standpipe

3) Open channel standpipe

All of the standpipes are built with 1.5" PVC fittings (adapted to the 1" bulkhead with a bushing). Each standpipe consists of a Sanitary-Tee topped with a threaded adaptor and a screw on cap. True union ball valves below the Tee are for adjustment of the system and/or isolation of the display if needed. The valve is only truly needed on the Siphon (middle) standpipe. The Open Channel standpipe (right) is fitted with an airline that is curled back over and attached just below the trim inside the overflow box. All caps are sealed with teflon tape so that they are airtight.

Something to keep in mind:

A submerged drain that is running at a full siphon will handle MUCH MORE flow than a similar drain that allows air in.

How the system works:

Notice that both the Emergency (left) and Siphon (middle) standpipes are capped. During normal operation the valve on the Siphon (middle) standpipe is adjusted (as shown in the render above) until the water level in the overflow box rises high enough that air is not being sucked into its down-turned elbow. This means that the standpipe is running at full siphon with NO air being sucked in. This is DEAD SILENT. However, it also means that the standpipe is NOT handling all of the flow from the return pump. This is where the Open Channel (right) standpipe comes into play. The Open Channel (right) standpipe is open to the air via the airline attached to it. Because air is allowed in, the standpipe will not siphon or gurgle. The excess flow that is not being handled by the Siphon (middle) standpipe quetly flows through the Open Channel (right) standpipe. Because the flow is very low, very little air makes its way to the sump.

This setup is VERY set-and-forget! It is self tuning over a very wide range and does not need to be touched once set. It operates silently and introduces very little air into the sump (if any). The caps can be removed to clean the standpipes if the situation ever arises.

Failsafe:

The setup has (2) failsafe features.

1) The Emergency (left) standpipe is set at a level slightly higher than the normal operating height of the overflow box. It is simply an up-turned elbow or strainer. If the water level rises above the normal operating level then it will flow down the Emergency (left) standpipe. This standpipe is also airtight. If the water level rises high enough the standpipe will begin to siphon and flush the overflow box.

NOTE:The Emergency (left) standpipe will also kick in during system startup. It takes a few moments for the air to be purged from the Siphon (middle) standpipe, during which time the water level in the overflow box may run high and into the Emergency (left) standpipe.

2) The Open Channel (right) standpipe is equipped with an airline that is attached in the overflow box. If the water level rises to the critical point of overflow and the Emergency (left) standpipe can not handle the flow (say due to blockage from algea or something) then the water will cover the inlet of the airline. The flooded air intake will in effect convert the Open Channel (right) standpipe into a full siphon standpipe, allowing it to handle much more flow. This will flush the overflow box and prevent flooding.

That's it... simple and effective!

This system MUST use the (3) standpipes that are described above. The emergency standpipe is a CRITICAL part of this design. Omitting the emergency standpipe is asking for a flood!

Here are some other renderings that show some of the detail. I prefer to have the strainers touch the bottom of the overflow box. I used a table saw to fabricate them out of street elbows. No snails or fish can get into the standpipes. If your overflow box is deeper, then standard bulkhead strainers or those from a place aquaticeco can be used.

The CAP on the Open Channel standpipe was drilled, tapped and then threaded to accept a standard John Guest airline fitting.

All (3) standpipes extend into the sump and terminate just below the water level.

[hr]

Last edited by BeanAnimal; 02/03/2008 at 02:49 PM.