snakeblitz33

Well-Known Member

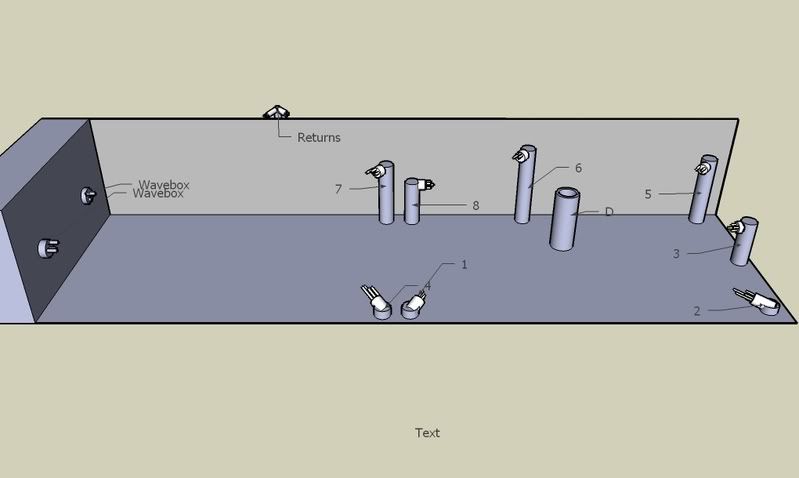

uhh, even if you measure it diagonally like that, you are only going to get the glass tall enough to fit the seam. Then, on both sides, it will only be wide enough only on one end or the other, and you will still have a gap.

Any either way you cut it, your are not going to get the width that you need.

Good luck to yah!

Any either way you cut it, your are not going to get the width that you need.

Good luck to yah!