Thanks guys, those are all good ideas. I got home tonight and checked the door to find that it has gone back to the way it was before (meaning flat again). I'm almost positive that temperature is playing a big roll here. When I eye balled it on Sunday and Monday (yesterday) the door was still way off and I mean twice as worse as what you see in the pictures above. So I pulled it down and checked it for trueness. It's pretty strait as is stands right now I checked it with a carpenters square. There are some slight imperfections along the seam in the middle but I had intended on feathering those out with the sander (still do).

But you can see were the back of the door had been catching and rubbing in the top corners. There is a dark looking smugde or rub mark on the 2x2 from where the two were touching.

So I'm kinda with you guys on thinking that the door could be salvageable. If I go ahead and make some relief cuts on the back of the door (probably dado style) to allow it to close as much as it wants to and a small adjustment to the hinge I might be ok. Granted I would like to get the stain and poly on there pretty soon. Adding some steal support to the back might be a good idea as well. I'm thinking possibly some angle iron would be best. Perhaps two pieces, one on each end or about 3" in from the end...that would leave me some room to install a friction hinge. I'd also like to get some of those dampener style hinges that Shawn installed on his door to keep the door from slamming shut if it happens to get let go of, either by me or by some curious on-lookers.

So maybe not too big a deal with the door (I hope). I'll try some things out and see what happens and let y'all know.

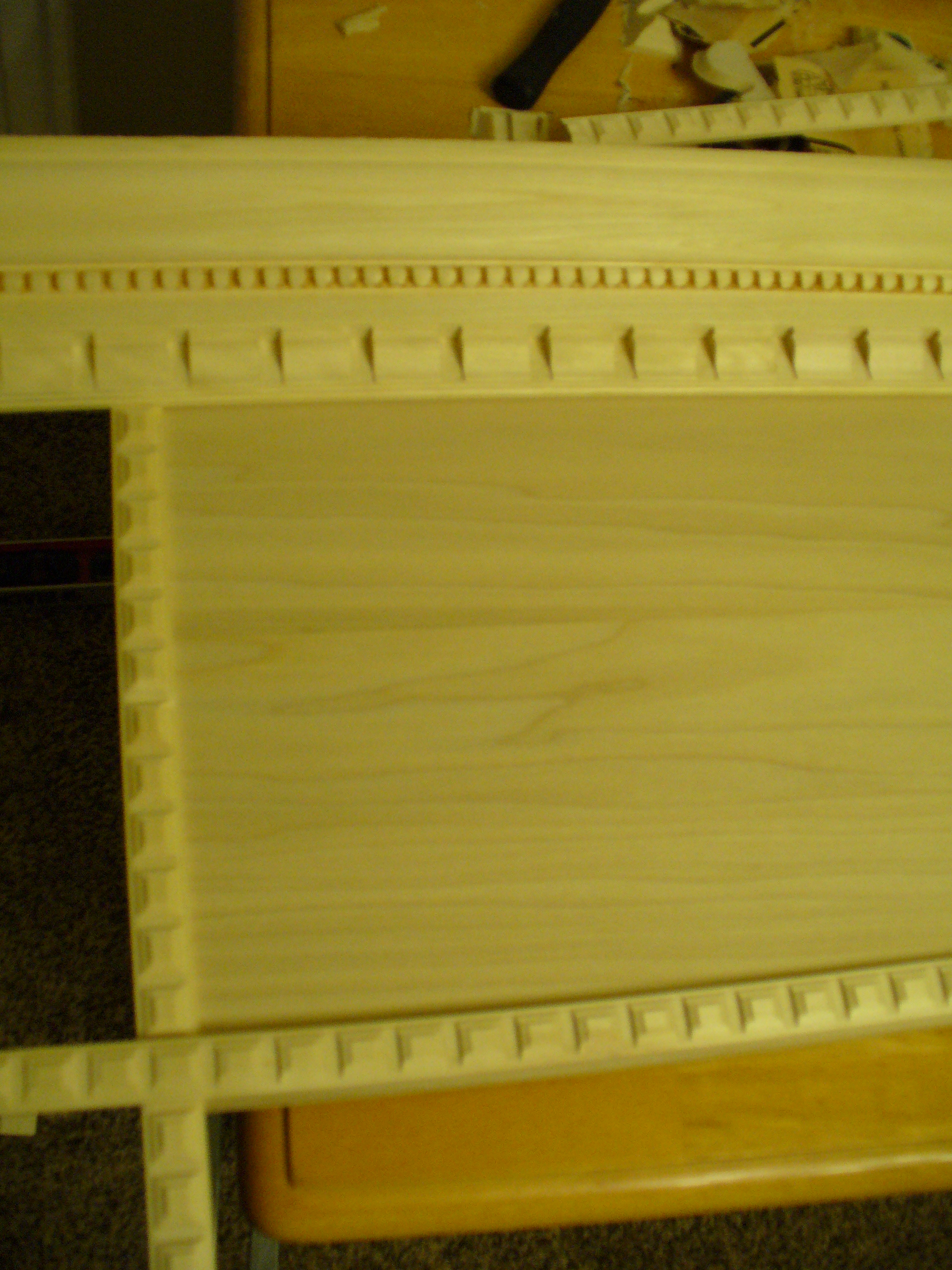

Here's a quick mock up of my idea for the door. I was planning on the crown going around the top ofcorse and then trimming the parameter of the door with the same stuff as on the other doors. It will over lap on the sides a bit, just enough to hide the gaps on the sides of the door and hopefully disguise the door all together from the average eye. Also kicking around the idea of putting a carving on the door for a little decoration. I seen a pretty sweet one that I liked with 2 lions standing facing off at each other and then some nice design coming off of the back of em. And possibly a carving of a lion head in the middle of each of the two front doors of the stand?? (still thinking about it)

Someone is slacking or did those outside / inside cuts finally drive him over the edge

Someone is slacking or did those outside / inside cuts finally drive him over the edge