2Quills, 120G Re-build thread.

- Thread starter 2quills

- Start date

2quills

Well-Known Member

Quote:

Originally Posted by acrylic51 http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364197

Looks very good....I would add the union on the cross piece. The center overflow increase surface skimming area......

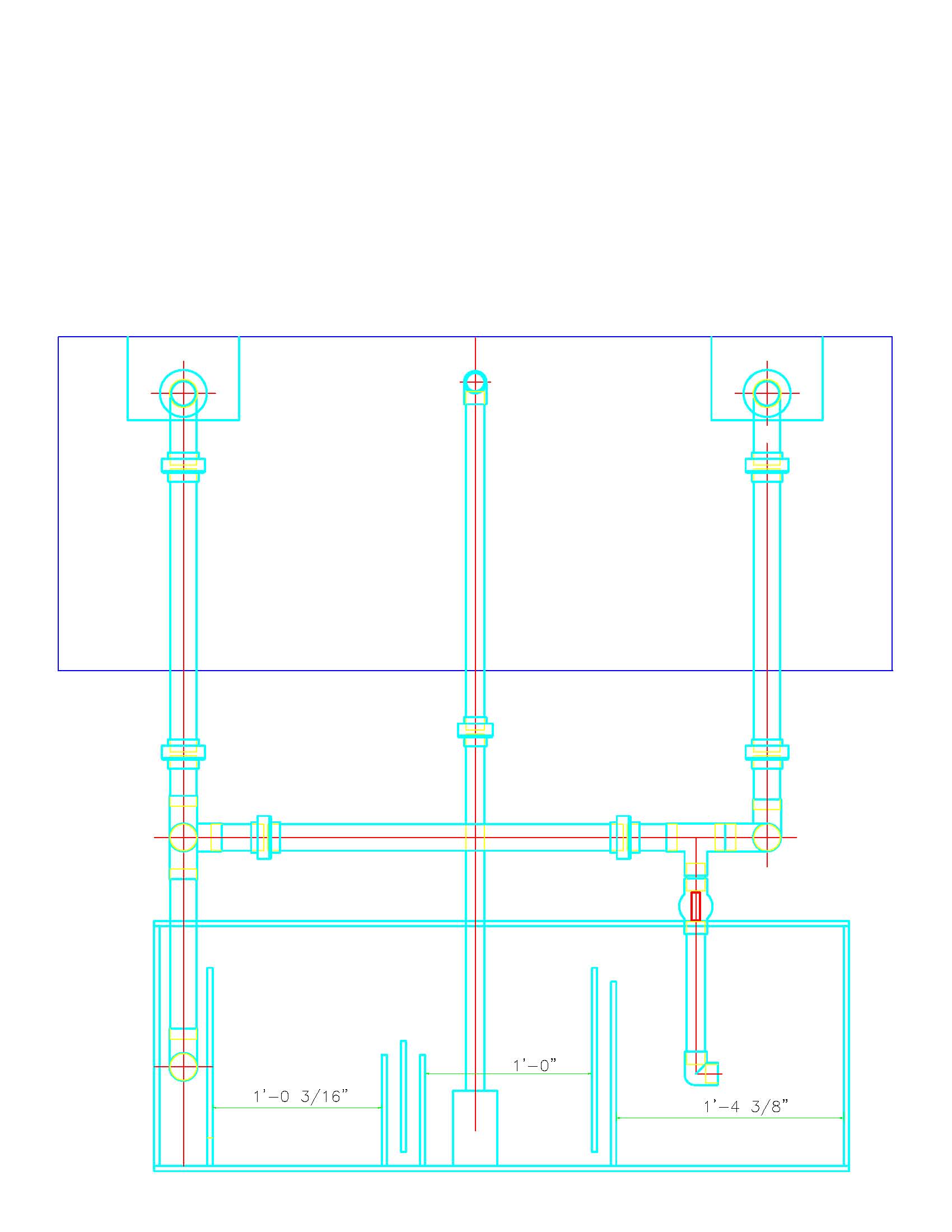

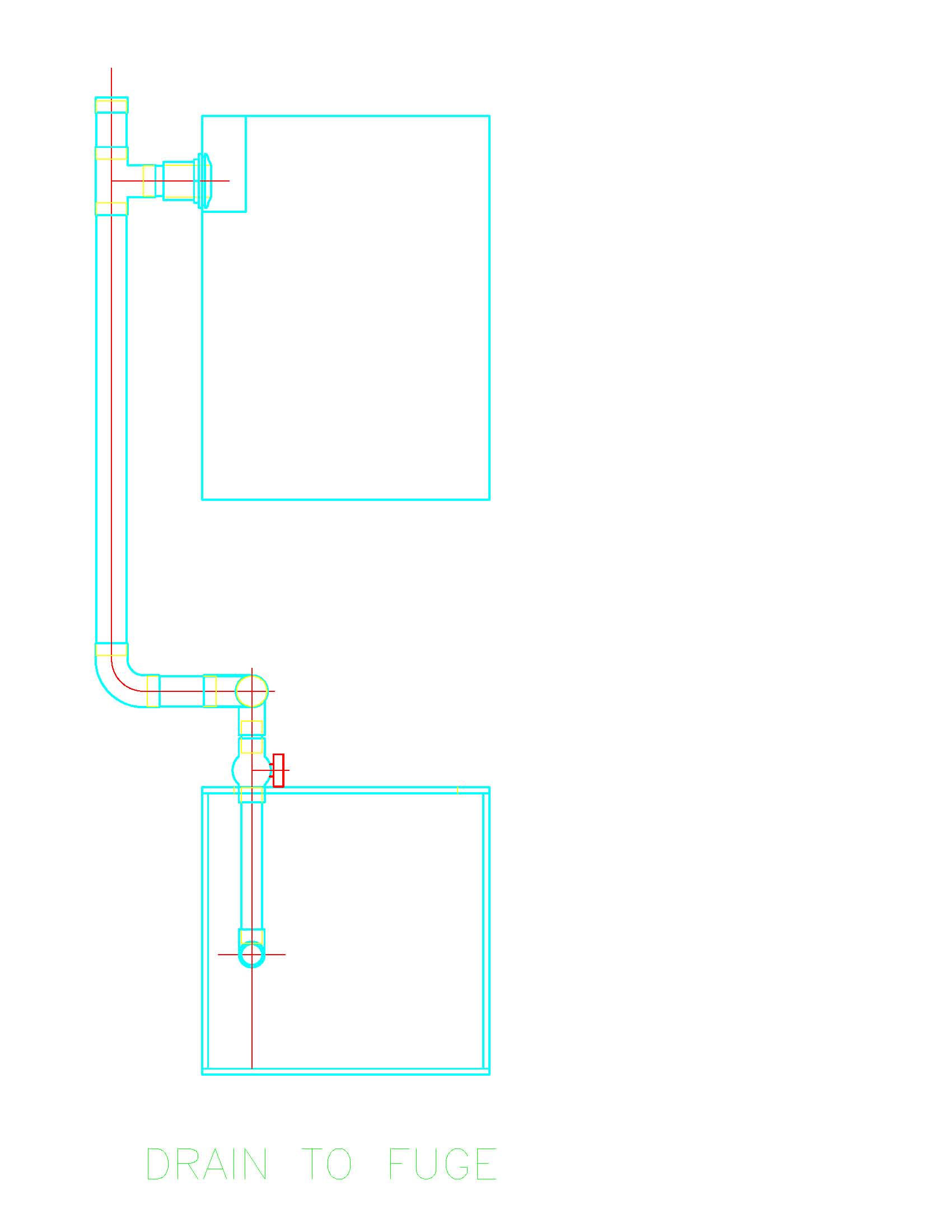

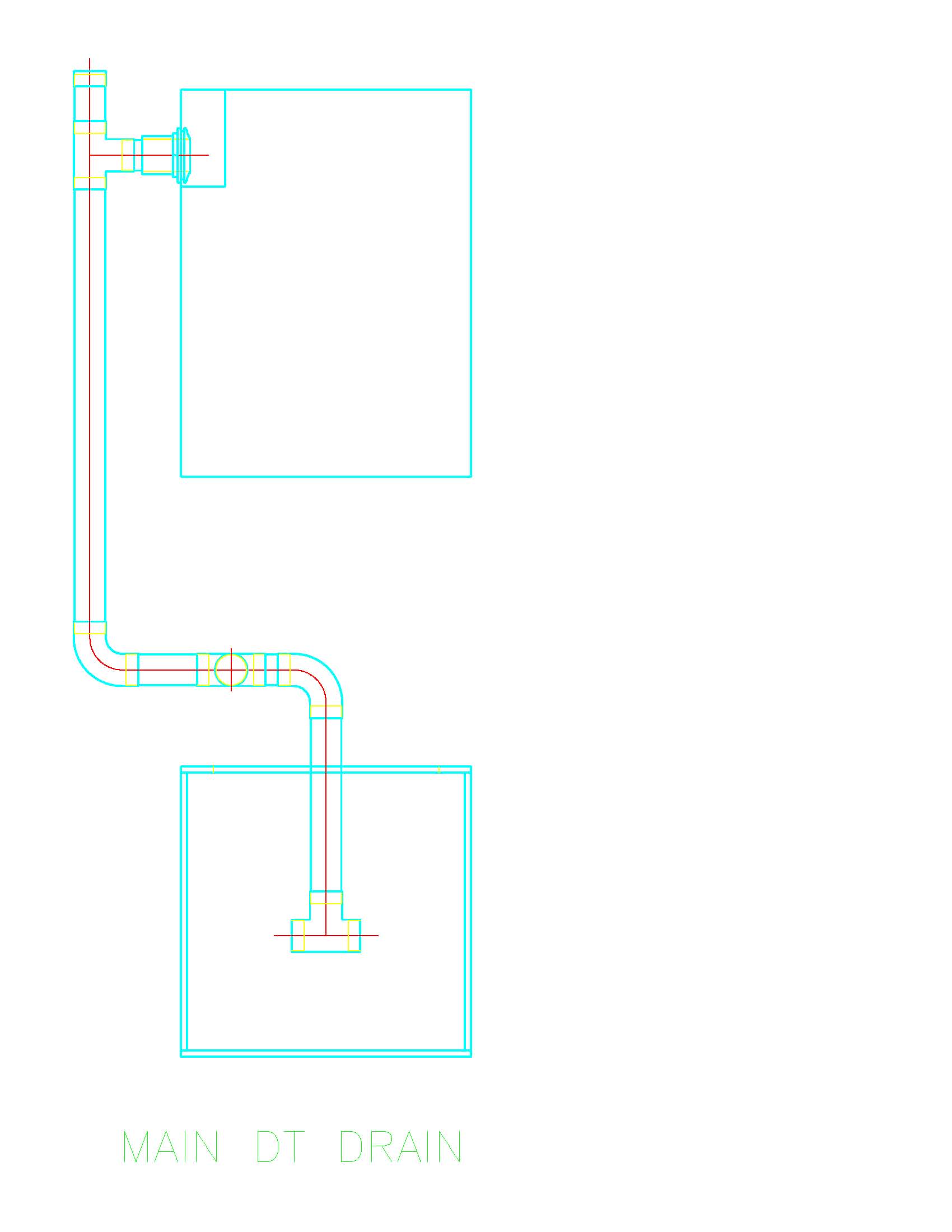

Thanks, Shawn. I was starting to wonder if they had worked you into an early grave over there. Yep, I plan on putting a union valve in the center of the cross piece. And probably two more, one on each of the drains dropping down into the sump. It's still not a finished product but the over all design I think I like. I did some talking with Al via pm and I've changed the size of the for the drain that feeds the fuge to 1-1/2" also. I'm hoping to get all of my control for the fuge with just the one valve and not actually have to utilize the one on the cross piece if I can help it.

Originally Posted by acrylic51 http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364197

Looks very good....I would add the union on the cross piece. The center overflow increase surface skimming area......

Thanks, Shawn. I was starting to wonder if they had worked you into an early grave over there. Yep, I plan on putting a union valve in the center of the cross piece. And probably two more, one on each of the drains dropping down into the sump. It's still not a finished product but the over all design I think I like. I did some talking with Al via pm and I've changed the size of the for the drain that feeds the fuge to 1-1/2" also. I'm hoping to get all of my control for the fuge with just the one valve and not actually have to utilize the one on the cross piece if I can help it.

al&burke

Active Member

It's not finished yet Corey, If you want I can add dimensions and would like to put it in a proper drawing format - do you think this is the final arrangement. Also Corey you can't really tell from the drawing but the sump/fuge is not centered with the tank, I assume you have enough room under the tank. I had to do this to make the left drain line come straight into the sump. ANd also on the horizontal drain run between the fuge and sump inlet are we going with a ball valve here as well.

Also I would like to make you a proper drawing of the sump, have you decided on material type and thickness?

On a side note I ordered the SWC 160 skimmer today for my upgrade.

Also I would like to make you a proper drawing of the sump, have you decided on material type and thickness?

On a side note I ordered the SWC 160 skimmer today for my upgrade.

2quills

Well-Known Member

Oh, ok, Al. Yeah the dimensions would be great to. Yes I do have enough room under the stand. I know the drawing is going to be hard to line up the plumbing with the sump. One of the changes that I made is that the two vertical drains coming out of the bulkheads on the backside of the tank are now being ran with flexible pvc and they are no longer strait up and down but they are curved a little bit. I take some pics when I get home, but I don't want you to have to go through the trouble of re drawing everything. I think what you have already looks good enough for illustrative purposes.

I'll have to get you a drawing of the sump. Changes being made there too. I'm going to drop the second baffle on the fuge side and run wide euro bracing on the ends to encorporate some bulkheads like you did on your build. I liked that idea.

Going to use polycast material. 3/8" will be 50" x 18" x 18". But I'll get you a better drawing of the actual dimensions of the baffles.

I'll have to get you a drawing of the sump. Changes being made there too. I'm going to drop the second baffle on the fuge side and run wide euro bracing on the ends to encorporate some bulkheads like you did on your build. I liked that idea.

Going to use polycast material. 3/8" will be 50" x 18" x 18". But I'll get you a better drawing of the actual dimensions of the baffles.

al&burke

Active Member

Quote:

Originally Posted by 2Quills http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364416

Oh, ok, Al. Yeah the dimensions would be great to. Yes I do have enough room under the stand. I know the drawing is going to be hard to line up the plumbing with the sump. One of the changes that I made is that the two vertical drains coming out of the bulkheads on the backside of the tank are now being ran with flexible pvc and they are no longer strait up and down but they are curved a little bit. I take some pics when I get home, but I don't want you to have to go through the trouble of re drawing everything. I think what you have already looks good enough for illustrative purposes.

I'll have to get you a drawing of the sump. Changes being made there too. I'm going to drop the second baffle on the fuge side and run wide euro bracing on the ends to encorporate some bulkheads like you did on your build. I liked that idea.

Going to use polycast material. 3/8" will be 50" x 18" x 18". But I'll get you a better drawing of the actual dimensions of the baffles.

On my 65 reef sump I just drilled oversized holes so my spa flexi tubing would fix in, on my 65 FW Planted tank build I wanted it sealed so when I eventually run CO2 I can cover the sump easily. Good idea with the flexible pvc - that is what I am using on my 65 reef sump, I never knew it existed and the nice thing is they are made to be glued in standard PVC fittings.

Originally Posted by 2Quills http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364416

Oh, ok, Al. Yeah the dimensions would be great to. Yes I do have enough room under the stand. I know the drawing is going to be hard to line up the plumbing with the sump. One of the changes that I made is that the two vertical drains coming out of the bulkheads on the backside of the tank are now being ran with flexible pvc and they are no longer strait up and down but they are curved a little bit. I take some pics when I get home, but I don't want you to have to go through the trouble of re drawing everything. I think what you have already looks good enough for illustrative purposes.

I'll have to get you a drawing of the sump. Changes being made there too. I'm going to drop the second baffle on the fuge side and run wide euro bracing on the ends to encorporate some bulkheads like you did on your build. I liked that idea.

Going to use polycast material. 3/8" will be 50" x 18" x 18". But I'll get you a better drawing of the actual dimensions of the baffles.

On my 65 reef sump I just drilled oversized holes so my spa flexi tubing would fix in, on my 65 FW Planted tank build I wanted it sealed so when I eventually run CO2 I can cover the sump easily. Good idea with the flexible pvc - that is what I am using on my 65 reef sump, I never knew it existed and the nice thing is they are made to be glued in standard PVC fittings.

2quills

Well-Known Member

Quote:

Originally Posted by Al&Burke http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364523

On my 65 reef sump I just drilled oversized holes so my spa flexi tubing would fix in, on my 65 FW Planted tank build I wanted it sealed so when I eventually run CO2 I can cover the sump easily. Good idea with the flexible pvc - that is what I am using on my 65 reef sump, I never knew it existed and the nice thing is they are made to be glued in standard PVC fittings.

That sounds good, I think I'll just drill the holes for bulkheads but maybe not use the bulkheads. Yeah the spa flex is nice. I've seen it used on pool and spa filter systems before but had never really thought about using it untill Shawn had mentioned it a while back.

Here's a shot of the back, you can see the bends in the pipe.

Shot of the front with the vertical piece on the cabinet face removed. When I take the doors and hinges off I'll have about a 1/2" clearance on each side of the sump to install it.

I need to pick up some more flex pipe for the verticals going to the skimmer and fuge (just have rigid on there now. I added the larger Tee for the fuge but think I'll try keeping the 1" size and see how it goes.

I'll save any final changes and tweaks for when the sump is finished. Using conduit clips for support.

Originally Posted by Al&Burke http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364523

On my 65 reef sump I just drilled oversized holes so my spa flexi tubing would fix in, on my 65 FW Planted tank build I wanted it sealed so when I eventually run CO2 I can cover the sump easily. Good idea with the flexible pvc - that is what I am using on my 65 reef sump, I never knew it existed and the nice thing is they are made to be glued in standard PVC fittings.

That sounds good, I think I'll just drill the holes for bulkheads but maybe not use the bulkheads. Yeah the spa flex is nice. I've seen it used on pool and spa filter systems before but had never really thought about using it untill Shawn had mentioned it a while back.

Here's a shot of the back, you can see the bends in the pipe.

Shot of the front with the vertical piece on the cabinet face removed. When I take the doors and hinges off I'll have about a 1/2" clearance on each side of the sump to install it.

I need to pick up some more flex pipe for the verticals going to the skimmer and fuge (just have rigid on there now. I added the larger Tee for the fuge but think I'll try keeping the 1" size and see how it goes.

I'll save any final changes and tweaks for when the sump is finished. Using conduit clips for support.

al&burke

Active Member

Right on Corey - conduit clips great idea I was wondering about that. That spa flex is great stuff, Shawn we owe you another beer. Is your return going to be hard piped or spa flex. I believe you are going with the Eheim 5000 with a 1" return. I got mine and it puts out. How much is the spa flex down in Texas. The 1" size up here was 2$/ft. Looking really good buddy.

2quills

Well-Known Member

Quote:

Originally Posted by Al&Burke http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364554

Right on Corey - conduit clips great idea I was wondering about that. That spa flex is great stuff, Shawn we owe you another beer. Is your return going to be hard piped or spa flex. I believe you are going with the Eheim 5000 with a 1" return. I got mine and it puts out. How much is the spa flex down in Texas. The 1" size up here was 2$/ft. Looking really good buddy.

Thanks

Return will be spa flex so I'll only have the one elbow at the back of the tank. I believe lowes had the 1" stuff for around $2.09'ish. The 1.5" wasn't cheap at all though. Lowes didn't have any so I stopped by a pool supply place and it was $3.70 per foot (which is actually cheaper than the braided vinyl tubeing). I think in the future I'll just spend a few bucks and order a couple of 25' roll online. It comes out alot cheaper and I'll have extra down the road for future projects.

Al, did the pump come with sch 40 connections or did you have to come up with some kind of addapter/fittings to hook up the return line?

Originally Posted by Al&Burke http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364554

Right on Corey - conduit clips great idea I was wondering about that. That spa flex is great stuff, Shawn we owe you another beer. Is your return going to be hard piped or spa flex. I believe you are going with the Eheim 5000 with a 1" return. I got mine and it puts out. How much is the spa flex down in Texas. The 1" size up here was 2$/ft. Looking really good buddy.

Thanks

Return will be spa flex so I'll only have the one elbow at the back of the tank. I believe lowes had the 1" stuff for around $2.09'ish. The 1.5" wasn't cheap at all though. Lowes didn't have any so I stopped by a pool supply place and it was $3.70 per foot (which is actually cheaper than the braided vinyl tubeing). I think in the future I'll just spend a few bucks and order a couple of 25' roll online. It comes out alot cheaper and I'll have extra down the road for future projects.

Al, did the pump come with sch 40 connections or did you have to come up with some kind of addapter/fittings to hook up the return line?

al&burke

Active Member

Quote:

Originally Posted by 2Quills http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364722

Hmmm...thats an idea to consider. Let me know how it turns out for you, Al.

Definatly my friend, I am going to try the Furnco first then if I have to cut the barb off I will do that and use a transition glue ABS to PVC just to make sure.

Originally Posted by 2Quills http:///forum/thread/378912/2quills-120g-re-build-thread/340#post_3364722

Hmmm...thats an idea to consider. Let me know how it turns out for you, Al.

Definatly my friend, I am going to try the Furnco first then if I have to cut the barb off I will do that and use a transition glue ABS to PVC just to make sure.