Quote:

Originally Posted by

2Quills http:///forum/thread/378912/2quills-120g-re-build-thread/420#post_3385414

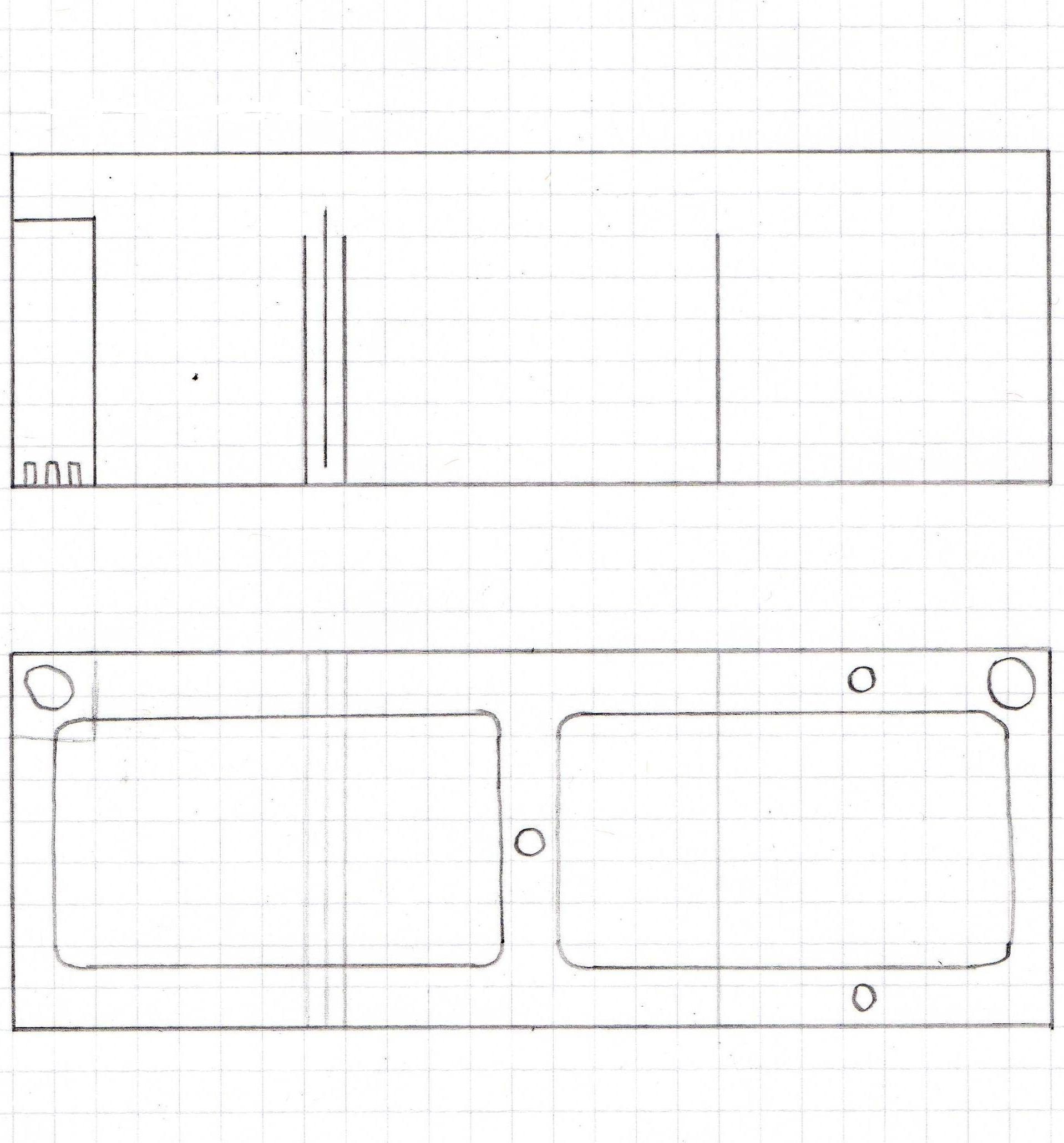

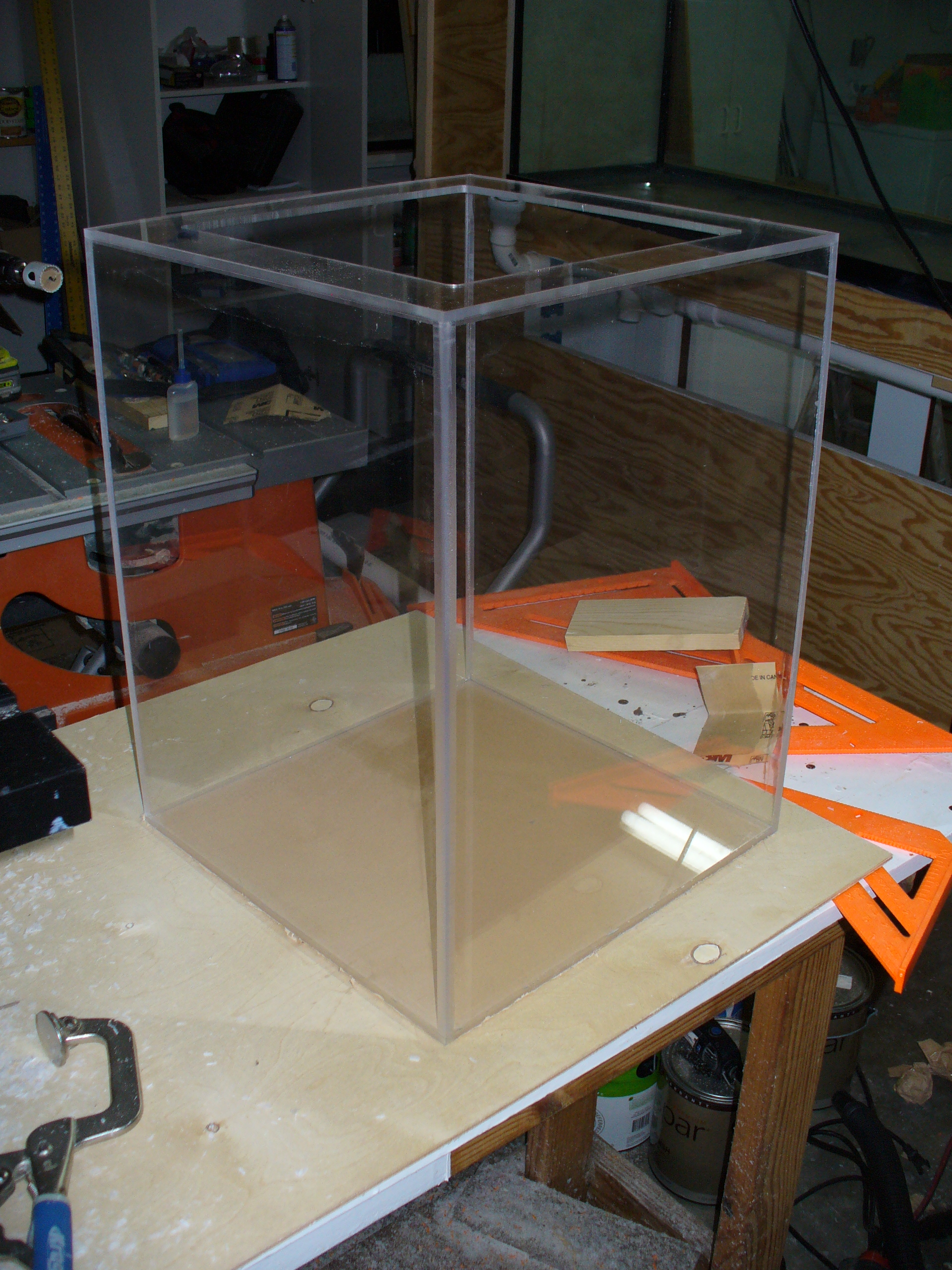

Some shots of my first DIY acrylic tank... 15 gallon ATO reservoir tank 14" x 14" x 18", 1/4" cast material with 2" euro bracing.

I figured that I would try to get a little bit of practice in before I go out and spend the money on materials for my sump. I think it turned out pretty good but time will tell once I leak test it.

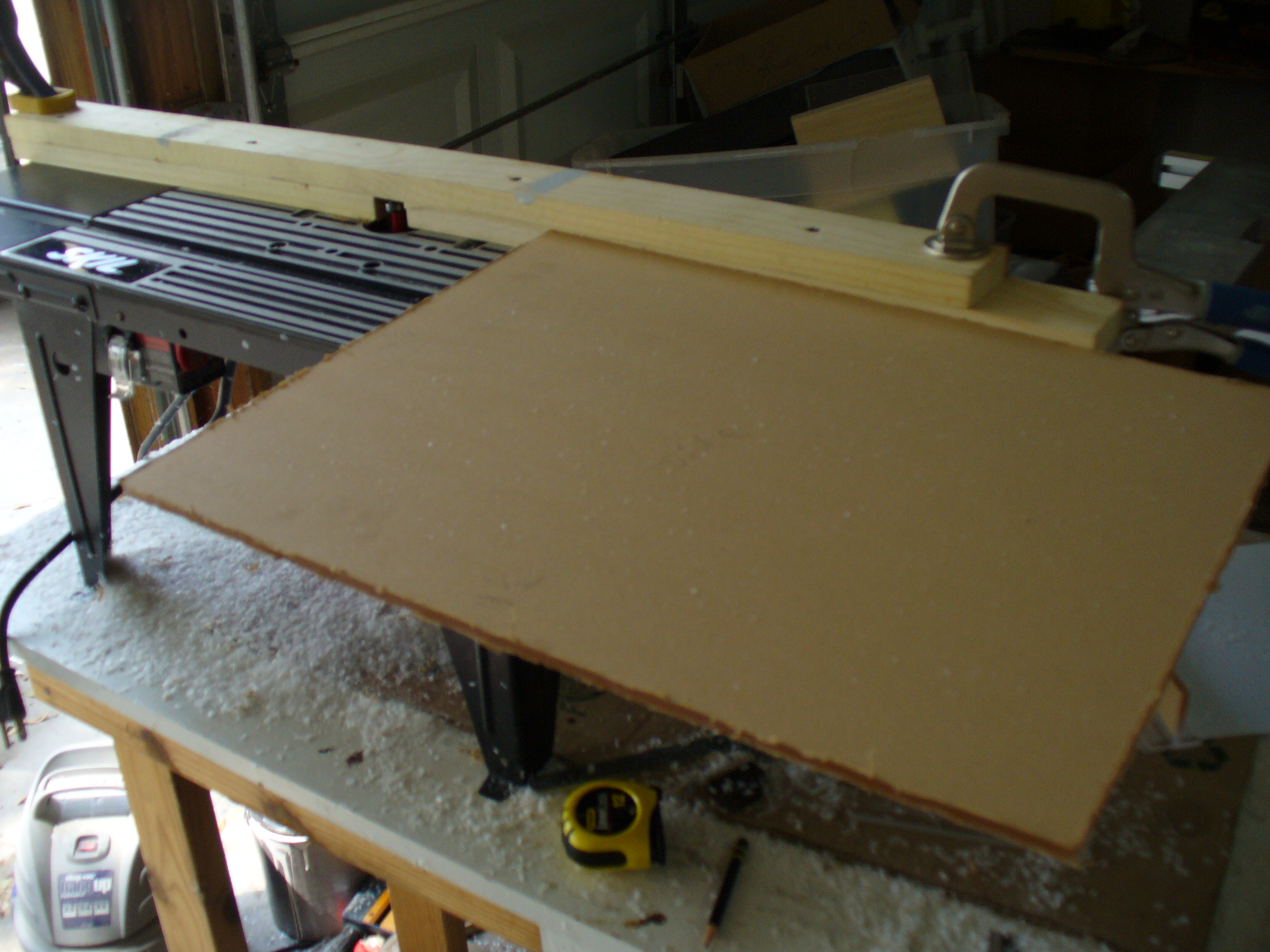

Cut pieces...

I made a jig for the router...I took approximately 1/8" off of the right side of the wood jig, essentially using my router as a joiner to clean up the edges. It took a little bit of tweaking with a couple of scrap pieces but it ended up working out great.

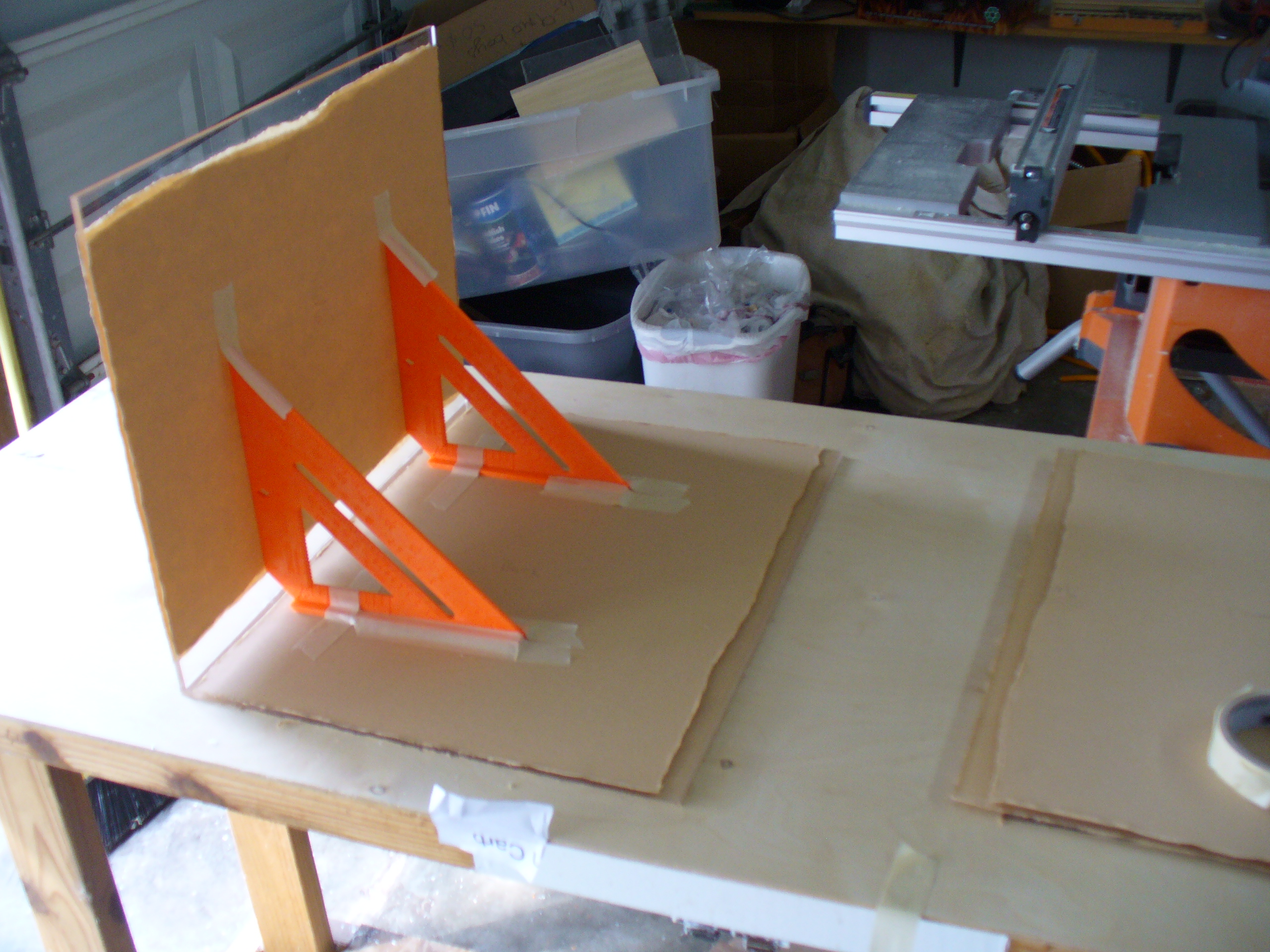

First joint coming together...

I did all 4 sides first and then set the whole thing on top of the bottom piece, welded all the way around the bottom then set a piece on top of the tank and added some weight.

The joints came out pretty clean, not perfect, but I think it will hold (fingers crossed).

>

Stay tuned for the results of the leak testing...coming soon.

Corey again everything looks good!!!!!!

Just a couple tips.....Don't use weight on the project when gluing. In our rational thinking we would assume we would want that but you really don't need any downward pressure on the glue joints.

Setup looks fantastic!!!!!! Like the idea on the router table....That use to be my issue with shaving a tic off the acrylic to clean up the edge....Still contemplating that fancy dancy freud fence setup with micro adjustments.....An easy trick to hold your squares in place is double sided tape....I read about it for years and finally broke down and bought some and after using it can't understand what took me so long......

I did read the height spec on the ATO and 18" is pushing it, but maybe a wider euro bracing could have solved the issue.....I don't think it's going to burst, might bow more as time goes on and as it absorbs.