Ok....after a hectic work week, and another just around the corner.....Ran into a little issue.....Mounted up my movable light rack only to find that it's "racked"....So all you wood guru's give me some advice on how to tweak it into place. The light rack does move, but with it being racked it's not as smooth as it should be, and getting it completely level is all but impossible. It's close, but most know how anal I am; and it will drive me insane from here to eternity.....Here's a couple pics, need ideas.

This is a shot of the basic construction. There is a 1/4" lip routed the whole way around except on the back panel so an acrylic splash guard can be slid into place to protect the LEDS. The corners are all braced as you see in the pic. The 3/4" routed slot, is where I am thinking of using 3/4" aluminum angle for the heat sinks to ride on so they are adjustable, but that idea might change after a thread I just recently stumbled upon, so mounted of the heat sinks, and adjustability might change.

Just another shot of the other side. This shot shows how the rollers are actually attached to the LED rig itself. The threaded rod allows me to adjust the height the LEDS will sit above the tank. you can also see in the background the door of the canopy open. I did use the friction hinge as you had suggested earlier Corey!!!!

Don't know if it will be heavy enough to handle the door being reinforced later on though.

Just another shot of the construction

This is a shot from the viewing area. The door of the canopy is open revealing the light rack. You can see in the pic it appears level, but you can also see that it is racked. I have double checked my levelness of the mounts and everything is fine. I know for a fact it is the light rack itself.

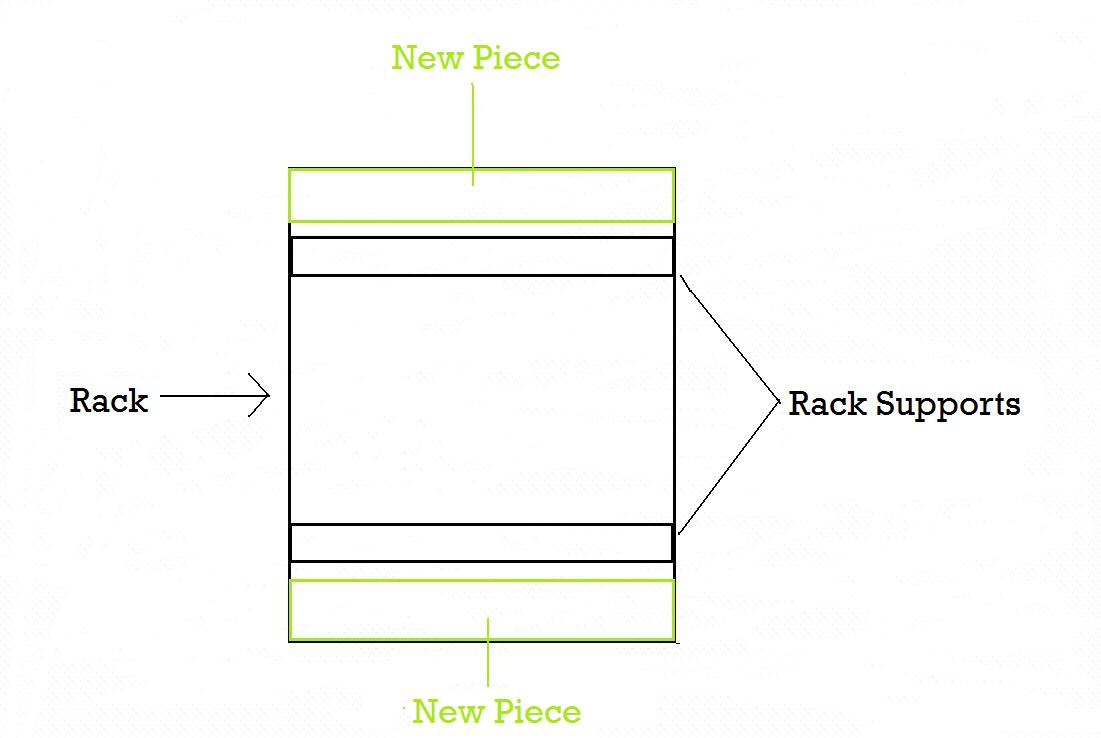

From this side shot you can really see that it is racked.....Any ideas on how to straighten? I do have a piece that goes in the center of the light rack to accept the acrylic splash shield, but don't think that is enough to tweak things back into place......HELP