acrylic51

Active Member

Not much major progress of lately....Just tying up a few loose ends, and trying to clear my mind....Still excited to get stain to the woodwork, but going over every last inch with a fine tooth comb, because I know as soon as I start staining I'm going to notice something.......Soooo.....

I had started working on my movable light rack awhile ago, and finally got it all stained and poly'd, and finally got them hung temp to work out a couple logistics.......Here's a couple quick pics...

There!!!! both light tracks are hung....and the roller mechanisms are in place....The threaded rod hanging from the roller assemblies are what will attach to the light canopy itself. The light canopy will be adjustable over top the tank, and when doing maintenance will be able to be pulled back from over the tank as well. Might have to incorporate some type of permanent lighting in the ceiling directly over the tank for maintenance purposes!!!!!

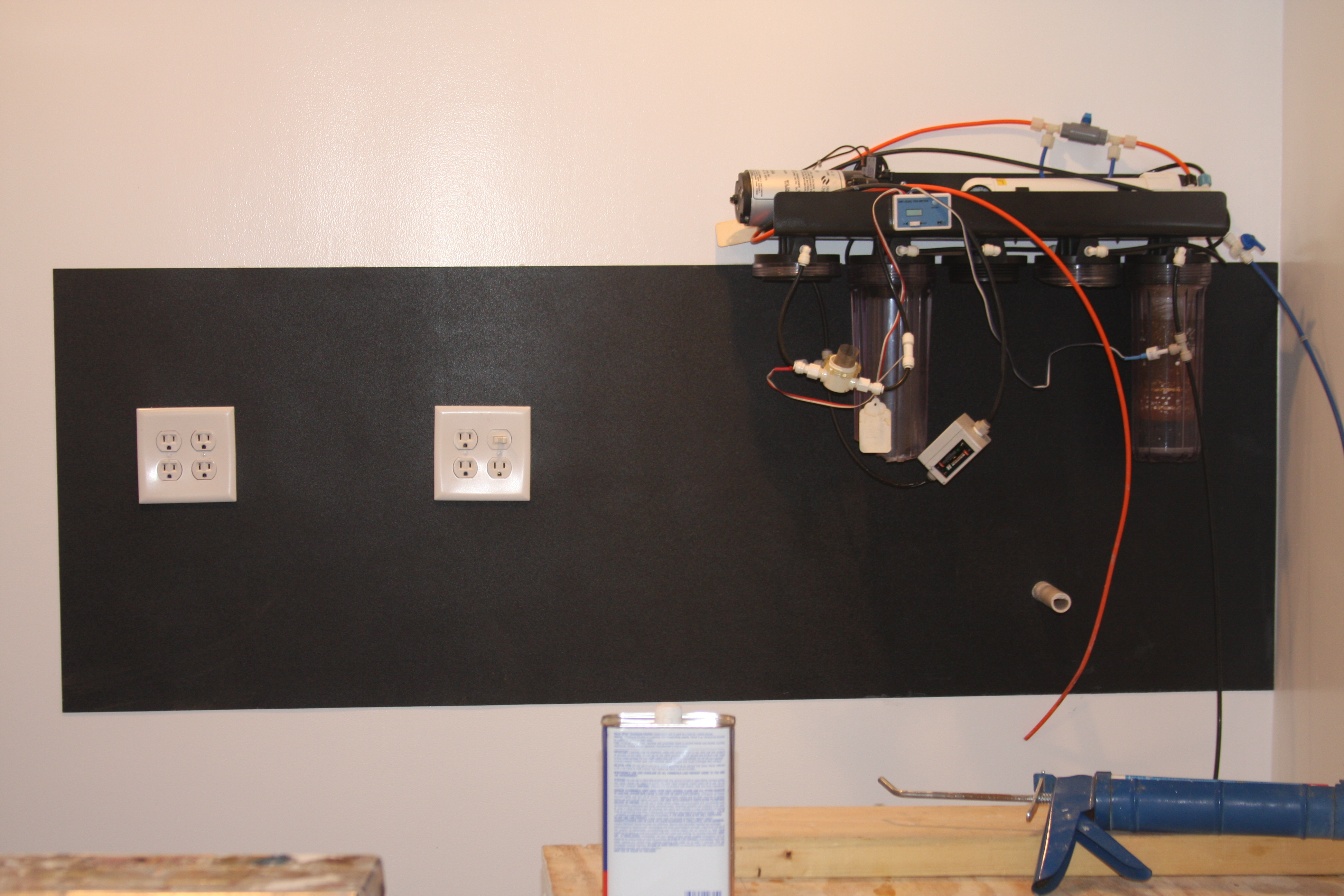

I had had my backsplash hanging around for a good while now and figured I better get it hung before something happens to it, or I use it for something else, which usually happens....I wanted a back splash on the wall underneath the RO/DI unit (which I haven't fixed yet), and where the prop and quarantine tank will be placed down the road. That is where the work station/tabletop will be built as well. That will be the area where all water tests and such will be conducted instead of the bathroom counter top.....

You might be wondering what that mysterious pipe is sticking out of the wall to the left of the orange waste line of the RO/DI unit??? That pipe/plumbing, is going to have a quick connect on that will be hooked to a pump, that during water changes it will pump the water out of the fish room directly to a drain in the laundry room on the other side of the fish room. No more hearing my wife complain about hoses all over the place!!!!!!

The last bit of the update, which really isn't any progress; well some way it is....you've always noticed the top of the stand cluttered with tools and what not!!!!! Well here's a couple shots with it cleared off, which might give a better perspective of the size of tank and how it looks somewhat uncluttered!!!!

I had started working on my movable light rack awhile ago, and finally got it all stained and poly'd, and finally got them hung temp to work out a couple logistics.......Here's a couple quick pics...

There!!!! both light tracks are hung....and the roller mechanisms are in place....The threaded rod hanging from the roller assemblies are what will attach to the light canopy itself. The light canopy will be adjustable over top the tank, and when doing maintenance will be able to be pulled back from over the tank as well. Might have to incorporate some type of permanent lighting in the ceiling directly over the tank for maintenance purposes!!!!!

I had had my backsplash hanging around for a good while now and figured I better get it hung before something happens to it, or I use it for something else, which usually happens....I wanted a back splash on the wall underneath the RO/DI unit (which I haven't fixed yet), and where the prop and quarantine tank will be placed down the road. That is where the work station/tabletop will be built as well. That will be the area where all water tests and such will be conducted instead of the bathroom counter top.....

You might be wondering what that mysterious pipe is sticking out of the wall to the left of the orange waste line of the RO/DI unit??? That pipe/plumbing, is going to have a quick connect on that will be hooked to a pump, that during water changes it will pump the water out of the fish room directly to a drain in the laundry room on the other side of the fish room. No more hearing my wife complain about hoses all over the place!!!!!!

The last bit of the update, which really isn't any progress; well some way it is....you've always noticed the top of the stand cluttered with tools and what not!!!!! Well here's a couple shots with it cleared off, which might give a better perspective of the size of tank and how it looks somewhat uncluttered!!!!