I'm just going to be applying 1 layer of biaxial cloth.....The stuff looks super thin already wet out in the pics, but when you actually handle the stuff it's pretty thick. Comparable to the old style cloth baby diapers more or less. Honestly a pain to cut, but I did find 1 good thing at Home Depot, and that is their Titanium scissors they sell, and they actually cut the stuff very easily and clean....Go figure Home Depot would actually have something I want or need.....

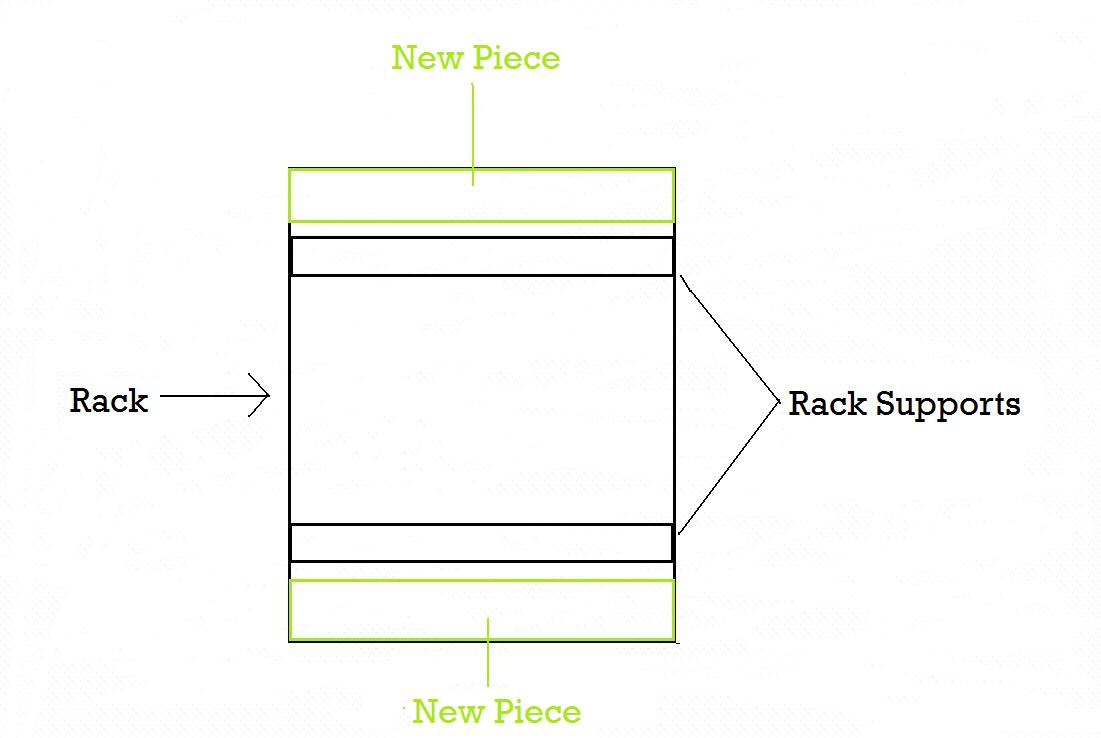

The entire inside of the tank will be wet out with 1 layer of 37oz biaxial cloth. Even the underside of the euro bracing will be fiber glassed as well. I don't know if any of you followed DMWZ's build thread over on RC, but he ran into an issue where he didn't get a good seal around the bracing on the top of the tank, which has caused him some issues. I'm not very concerned about that issue, since I did what I call a "primer" pour of epoxy. I poured a thin layer maybe a 1/16th thick in the entire inside of the tank including the bottom side of the euro bracing as well.

After the initial "primer" pour was done, and before I could start wetting out the fiberglass I had to scuff the surface with 60 grit sandpaper. I called West Systems tech people and asked them personally, and this was their recommendation. I not only called 1, but 3 times total, just to make sure. During normal build as long as there isn't more than 8 hours between pours no sanding is required, but because of delay with getting epoxy and work schedule that isn't always practical. So after the sanding was done with 60 grit, the fiberglass was cut and fitted and then epoxy was measured, mixed and poured on top of the fiberglass and then you start working the epoxy outwards towards the edges. You have to watch that you don't put to much epoxy, or the fiberglass will float, which will be another issue for you.....At this point you can wait for the epoxy to setup and then pour another coat, or as in my case, I had down time, and I have to scuff again with 60 grit, to take high spots out, and take away the shiny areas, and give the next coat of epoxy a good bonding surface. You will keep pouring until the fibers in the cloth are completely embedded in epoxy. I figure the next coat should conceal the fibers. Then I will probably do another 2-3 thin pours, and then I will add pigment to the next batch of epoxy and start tinting the inside of the tank. I'm planning on tinting the epoxy for the bottom of the tank with a white pigment, and the back will be tinted black. I chose black since I'm seriously leaning towards using acrylic for my viewing panels for a couple reasons, that I won't get into now; other than the end where the external wavebox will be, will be a black acrylic panel with the wavebox, glued to the outside of that panel, and cutouts for the Tunze's to nestle into the openings to shoot out into the tank. The wavebox will house (3) Tunze's total. I might have to fab up some fancy grates for the wavebox like I did for Flowers fuge setup.

As far as the staining of the stand off corner piece; yes Corey I went with your recommendation......Honestly each time I stain with it I get a different look it seems, but each 1 I like a little better. When I first applied the stain I didn't care for it, but the next day I was actually pleased......The bar ledge wasn't actually planned the way it is, but then I started thinking about when company does come over which I hate!!!!! There always seems to be a drink of some sort by my tank. I figured make ledge wide enough to accomodate a beverage, so it won't spill on the floor, but the finish has to be tough enough to withstand a sweating cup or beer.....The epoxy will easily do that. I wish I could do the whole stand and canopy with the epoxy, but it would honestly be a PITA turning and moving the pieces with all the detail trim work to get good coverage, and not having areas super thick. A flat surface is super easy to get a good thin coverage, and easy to work any bubbles out of.....

Side note Corey WoodCraft has the bar top epoxy on sale this month for like $28 or $38 bucks.......I might have to sneak there this weekend and pick some up and hide it........