Thanks guys!!!! Where is Meowzer when we need her......She might be having a cocktail.......

Just kidding Meowzer.....

Just some updated pics.....Hey Al here is the pic of the latest water vat I picked up last week. Still haven't gotten it into place, but hopefully soon....I had bought a pump for the mixing station itself, but a buddy had a pump go down for his return, and I gave him the pump to use till he gets his main return pump back into service......

Al it's a 165 gallon holding tank with the man hole on the top.....I'm gonna drill it and use uni seals when I get the pump back and ready to hook up the mixing station....They had 7 when I was there last Thursday, so hopefully they have another reject next time I get by.....You can see the indentation on the upper left top before it goes into the cone section. That is why it was a blemished vat and they can't sell at full price. Check out Chemtainer.com.....Look in their clearance section, but I have to forewarn shipping is a bit expensive on stuff like this.....Not heavy, but the space it takes up.

I was hell bent on tackling some of my cabling/power issues this weekend.....I was dreading it, and kept putting it off. I by no means want any cords laying in the bottom of the stand or draped over things, so I started hunting around for cable managing ideas....I had looked at Graingers and a few other places, but cost was a major issue....It was different if I was going to use tons of it or use it often, but most if not all the places what I was interested in you had to buy by the case, which wasn't cheap......So I started searching other alternatives....I started looking at Lowes for cable.....I wanted to use 12/3 cable....I know I overdue everything, but it keeps me in my comfort zone......Needless to say cable was expensive......

My issue with cable is I wanted to be able to strategically place outlets around and on the stand where I needed for cable management.....With that being said each outlet needed to be wired totally separate from one another, so when the Apex is in place each plug/component could be controlled by a separate plug/channel on the Apex......so your basic surge protector or outlet strip wouldn't fit the bill......So again after agonizing over the price of cable at Lowes, I decided to give Harbor Freight a try and figured I could get some cheap extension cords to fit my purpose.....

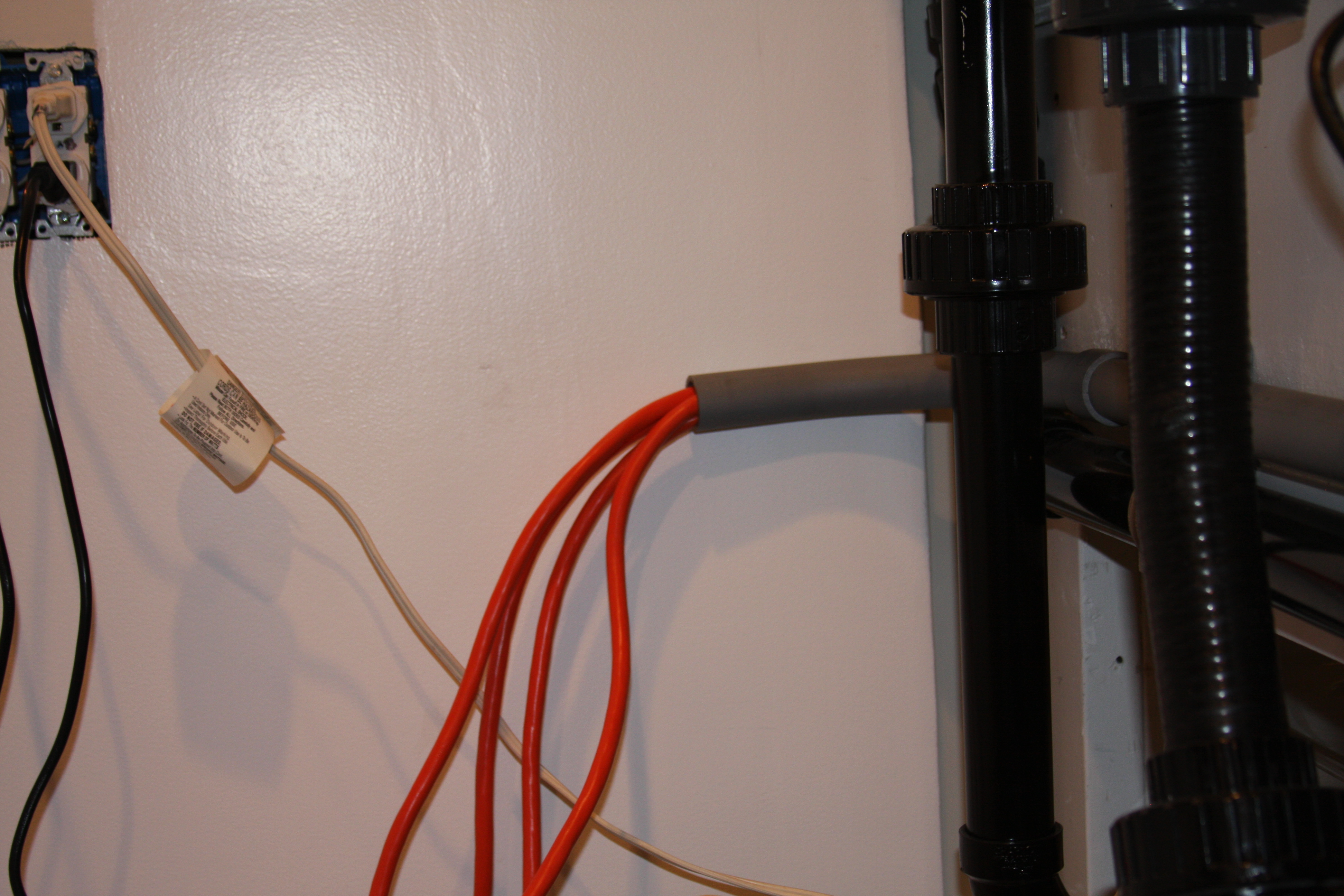

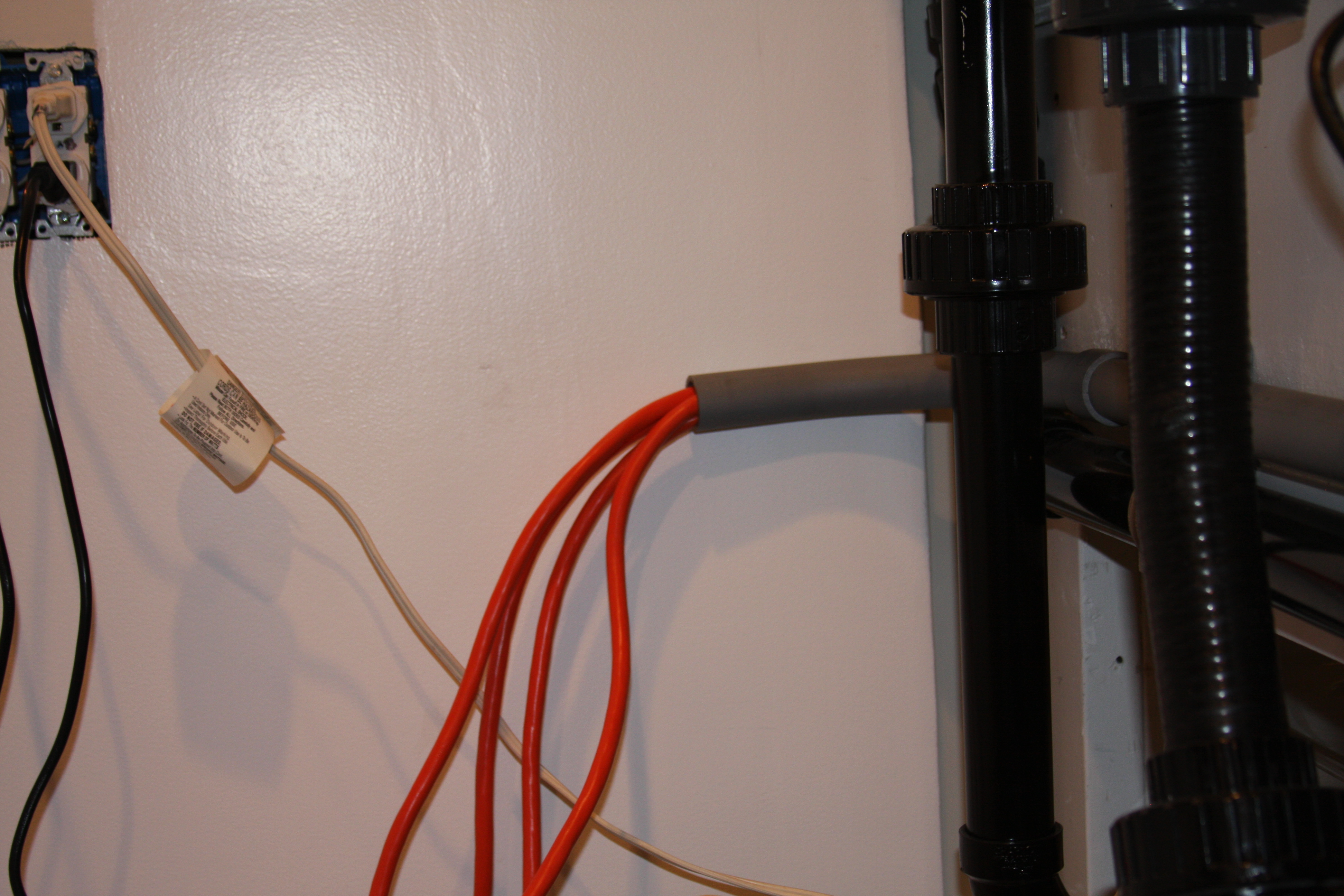

I got a 100' 12/3 extension cord for $50.00......a heck of a lot cheaper than 100' of cable from Lowes for a $1.30 per ft......You can see I have already whacked the end off..........

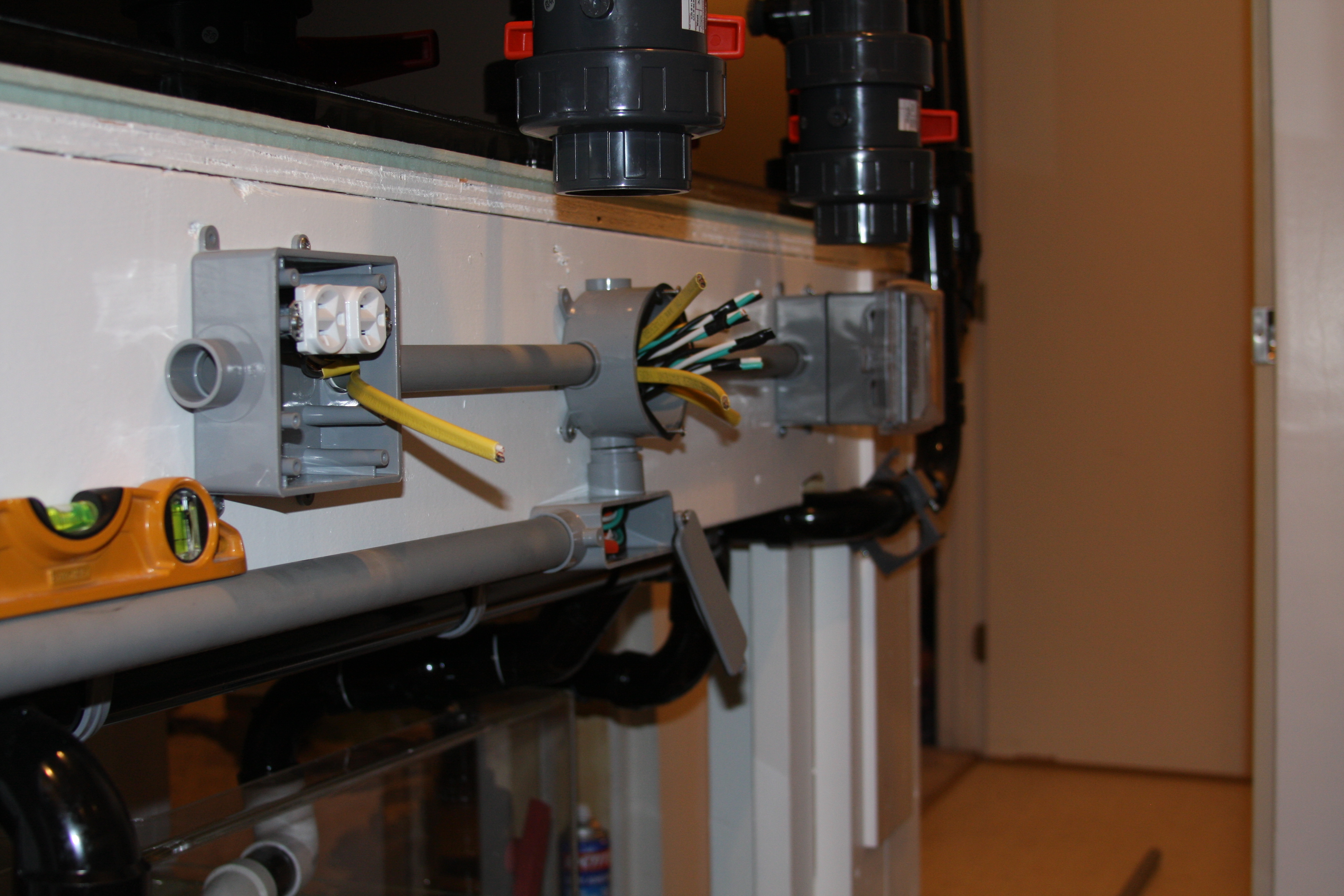

As you can see from this 1st pic, that I hacked the cable up into 4 sections I needed......This was the start of my cabling nightmare.....Trying to fish 4 12/3 cables through 1" conduit is a real PITA......Actually on the 4 cable a little WD40 worked wonders.......

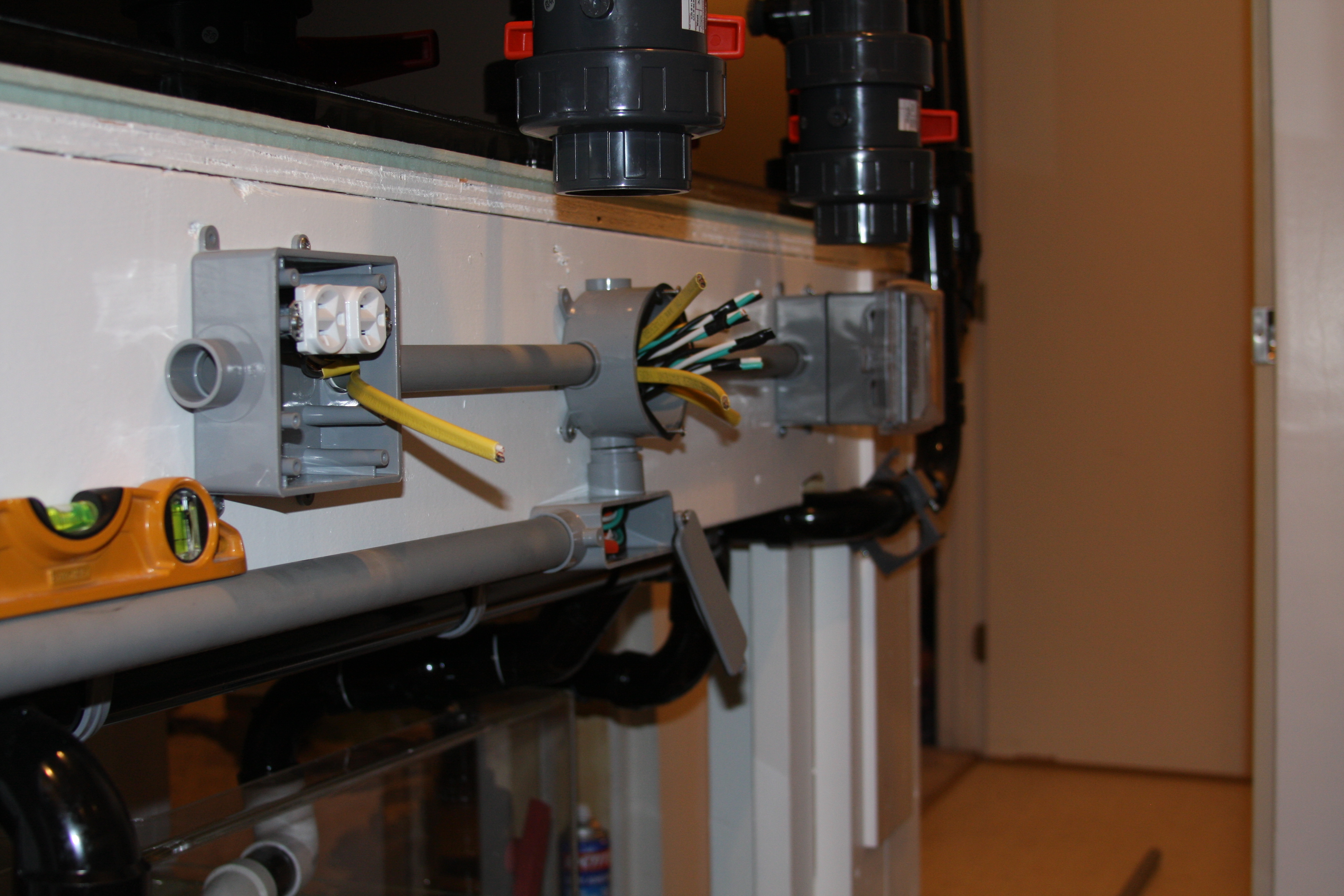

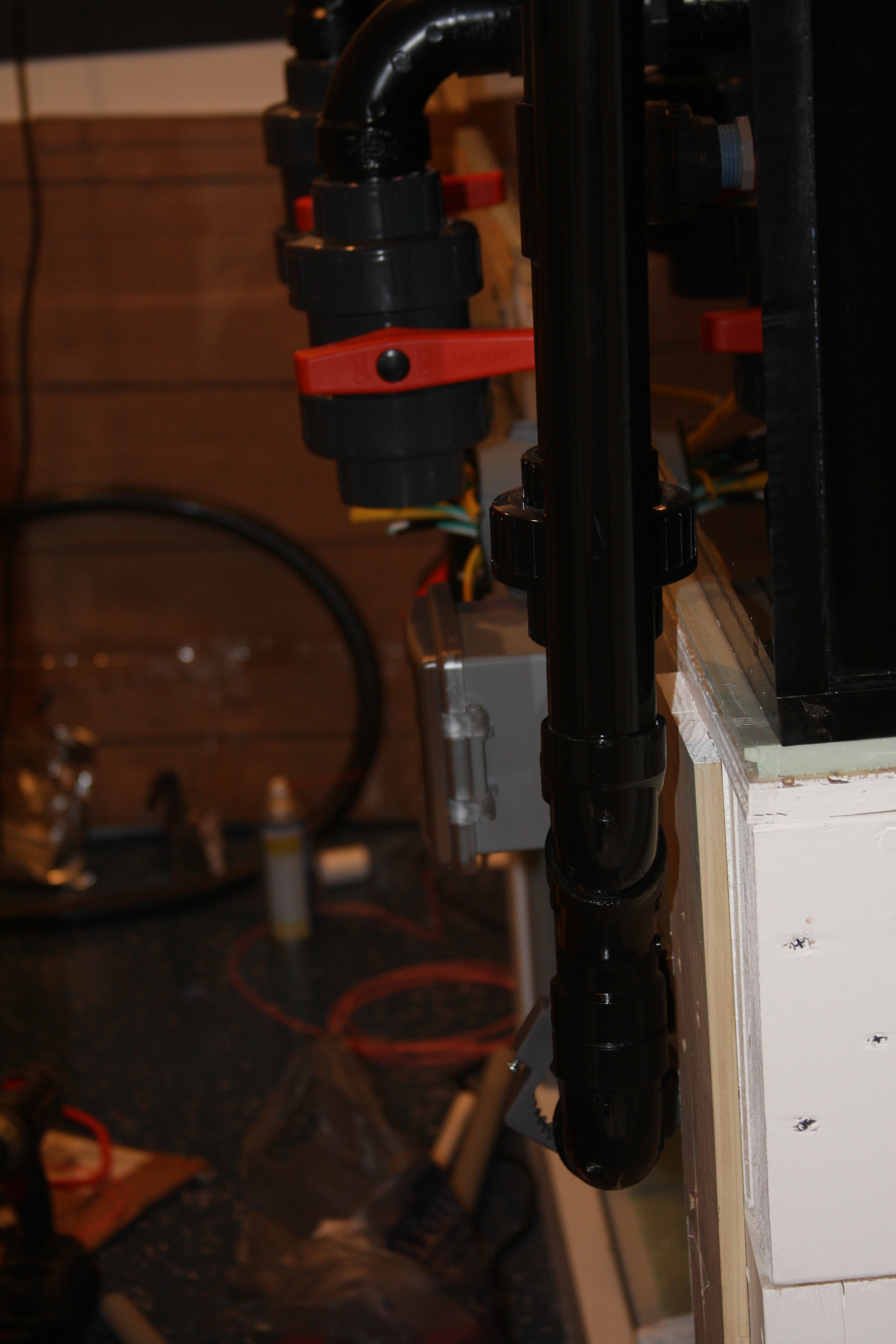

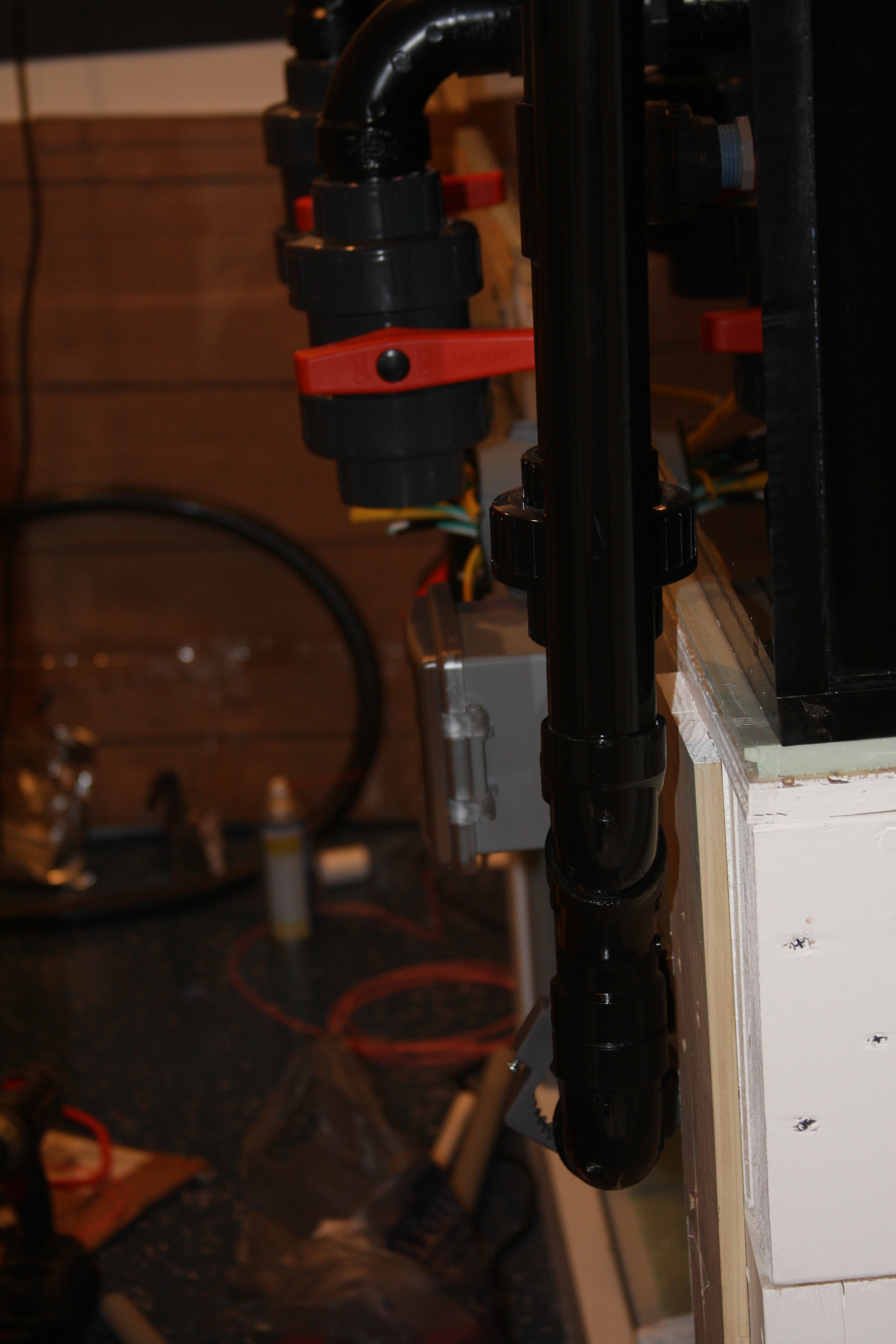

As you can see I got all the cabling through the 1" conduit line beneath the outlet boxes above.....(I have to show where my patiences wore thin and cut a section of conduit out).......Needless to say all the cabling comes into the small rectangular junction box on the bottom ( cover hanging off) and it is then fed into the upper junction box. The power cables in the upper box are the green/black/white wires bound together.....The yellow lines sticking out of the round (upper) junction box are actually the lines running to (4) individual recepticals.....In the (upper) round junction box all the splices and connections were made to feed juice to the individual outlets.....

These are standard 20amp outlets.....I only put (1) GFCI outlet which is inside the far box which is where my heaters will be plugged into.....I'm not to concerned about running GFCI's on all my equipment.....Everything is external except the heaters, so that is my biggest concern. All the outlet boxes are then covered with outdoor (in use) weather protective covers.....

Just a quick shot of the outdoor covers I used on the outlet boxes on the stand......Sorry about the bad pics and the mess.....