2quills

Well-Known Member

Quote:

Originally Posted by Flower http:///forum/thread/380517/flower-s-sump-fuge-build/620#post_3322504

Fantastic!

I thought a hose connects to the overflow... with a barbed thingy.. It's late, I have to go to work, I can't go look now... but I will to get out the overflow tomorrow and see how it attaches. Looking at your pictures with what I have here will help allot.

Does it have to be glued...and if so what exact type of glue? How long to let it set before I can use it?

You are correct, it does connect with a hose barb fitting. In CPR's video of their overflows they make mention on how they actually recommend going with a larger size drain line if you can. It just increases efficiency and will hopefully help in the area of quieter operation. So what we've done is come up with an adapter that increases the diameter of the drain size so that we can incorporate it easily into the bulkhead that CPR has provided for you. Since they sell slip style bulkheads then this is how we can adapt it, by glueing it to the bulkhead.

And this is that adapter. I used a 3/4" bulkhead and pipe next to the 1-1/4" adapter as a reference to how it will connect.

The areas in red here are where you'll need to glue. PVC glue and primer.

You'll take this hole piece with the hose and everything and then glue "A" to the bulkhead. Then you'll attach "B" together underneath that stand.

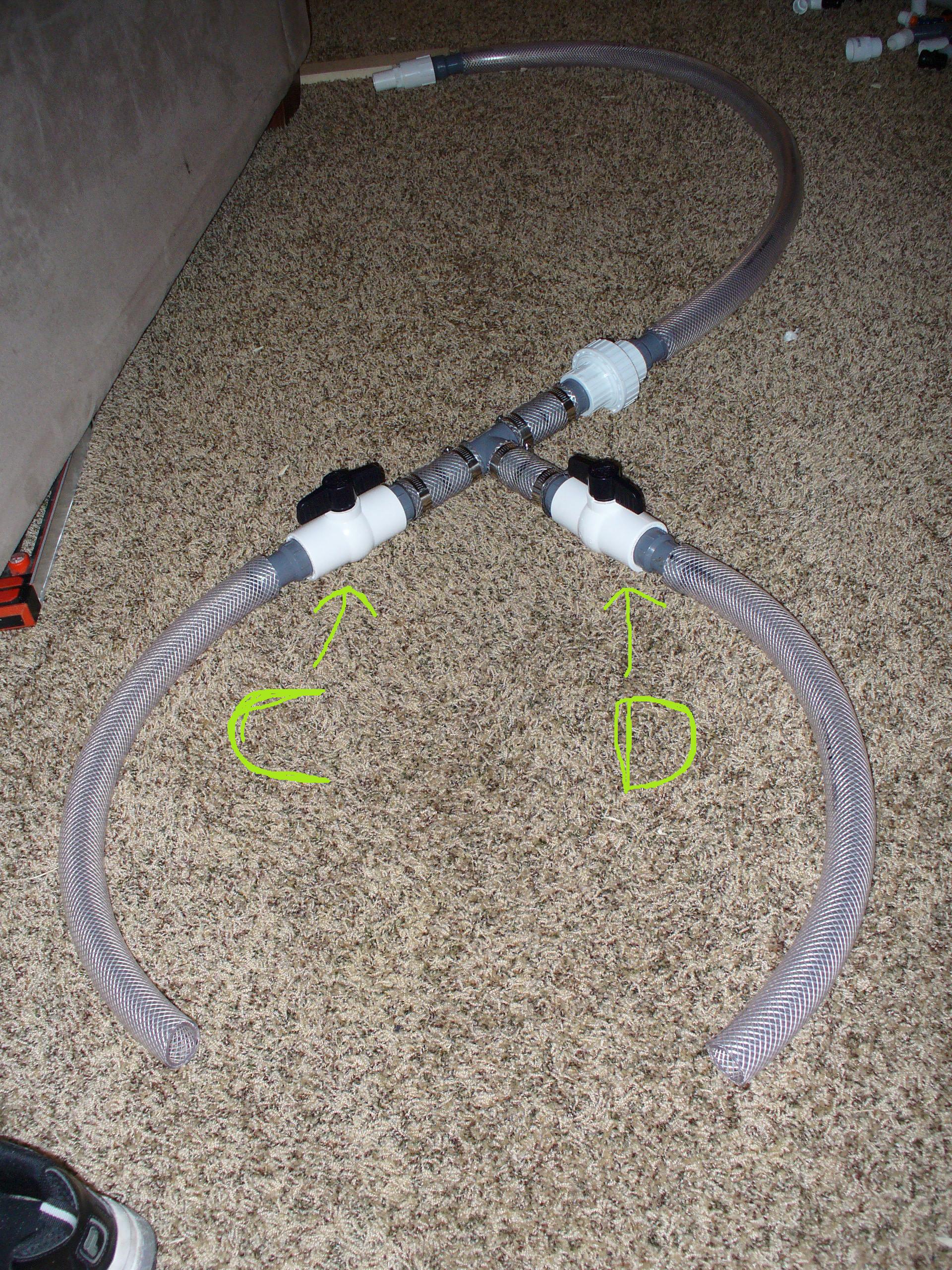

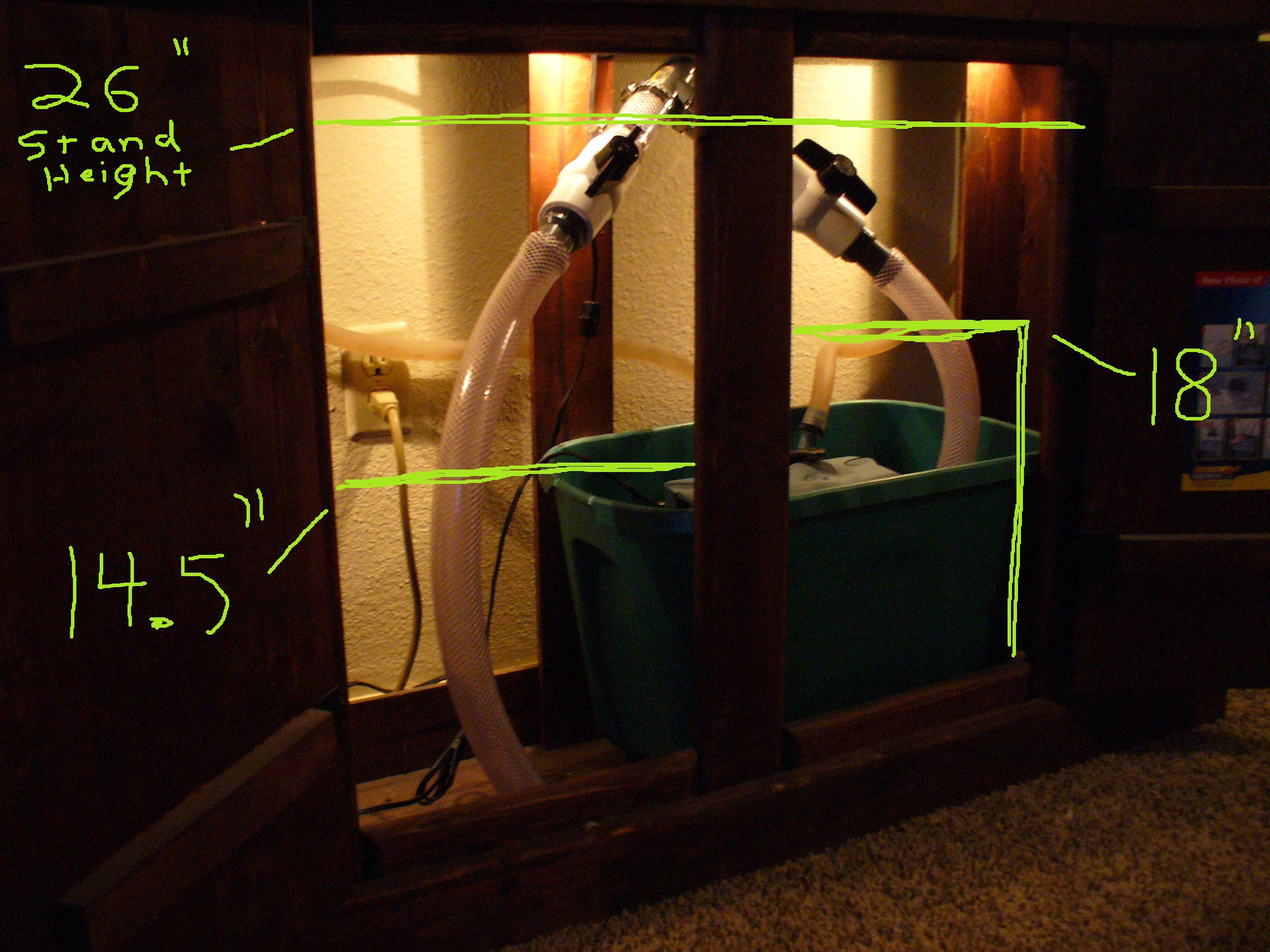

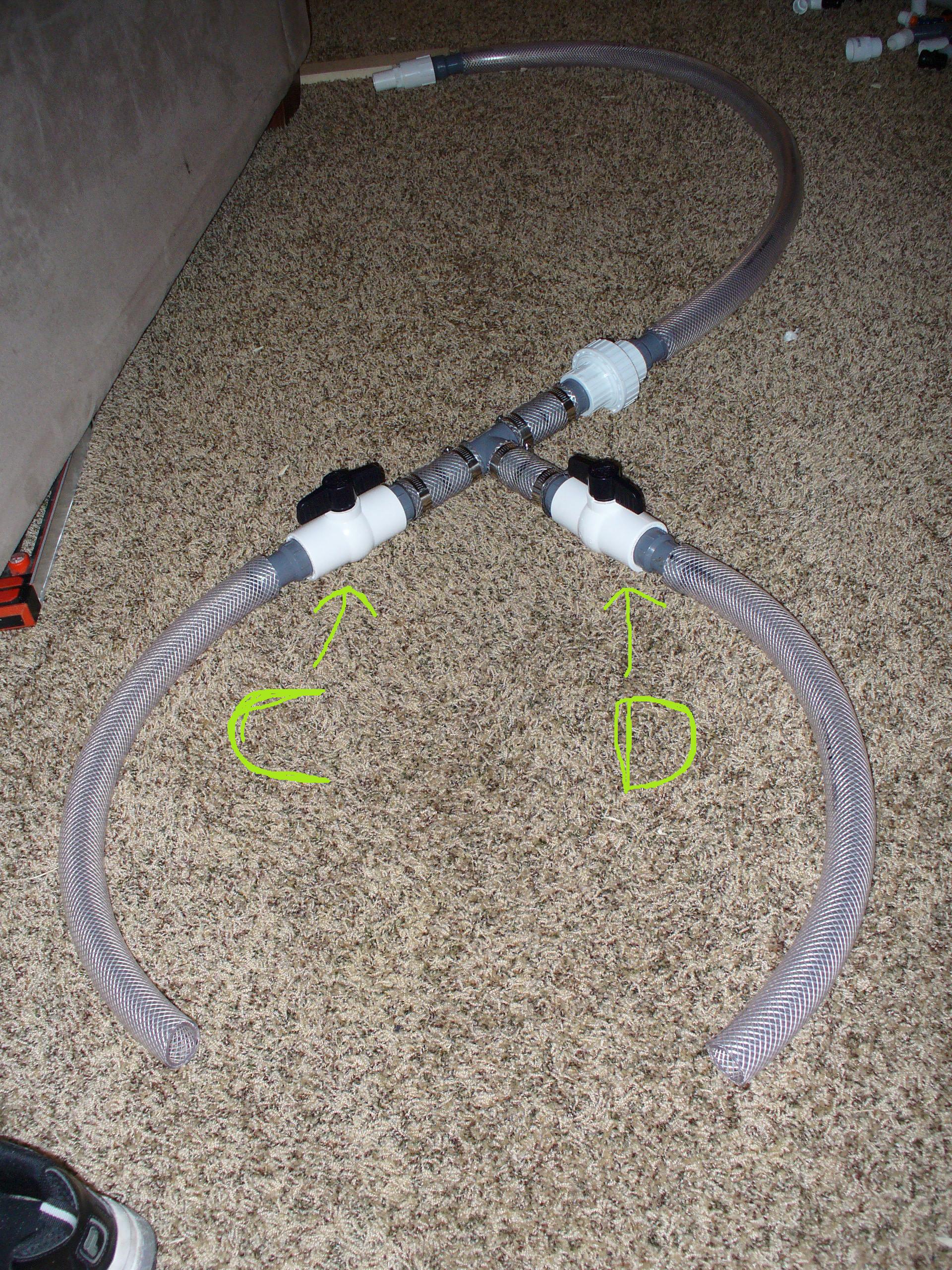

And these two "C" and "D" is where your drain splits...."C" goes to the sump side with the skimmer and "D" goes to your fuge. The "C" valve (depending on how the plumbing ends up laying out) should always remain fully open. Valve "D" will be kept aproximately three quarters of the way closed. This should alow for less/slower flow going to the fuge...and more going to the sump. There will probably be a little fine tuning that you'll have to do by openeing or closing the fuge valve a little bit once you get things going.

Originally Posted by Flower http:///forum/thread/380517/flower-s-sump-fuge-build/620#post_3322504

Fantastic!

I thought a hose connects to the overflow... with a barbed thingy.. It's late, I have to go to work, I can't go look now... but I will to get out the overflow tomorrow and see how it attaches. Looking at your pictures with what I have here will help allot.

Does it have to be glued...and if so what exact type of glue? How long to let it set before I can use it?

You are correct, it does connect with a hose barb fitting. In CPR's video of their overflows they make mention on how they actually recommend going with a larger size drain line if you can. It just increases efficiency and will hopefully help in the area of quieter operation. So what we've done is come up with an adapter that increases the diameter of the drain size so that we can incorporate it easily into the bulkhead that CPR has provided for you. Since they sell slip style bulkheads then this is how we can adapt it, by glueing it to the bulkhead.

And this is that adapter. I used a 3/4" bulkhead and pipe next to the 1-1/4" adapter as a reference to how it will connect.

The areas in red here are where you'll need to glue. PVC glue and primer.

You'll take this hole piece with the hose and everything and then glue "A" to the bulkhead. Then you'll attach "B" together underneath that stand.

And these two "C" and "D" is where your drain splits...."C" goes to the sump side with the skimmer and "D" goes to your fuge. The "C" valve (depending on how the plumbing ends up laying out) should always remain fully open. Valve "D" will be kept aproximately three quarters of the way closed. This should alow for less/slower flow going to the fuge...and more going to the sump. There will probably be a little fine tuning that you'll have to do by openeing or closing the fuge valve a little bit once you get things going.