Major update:

Well, I had trouble uploading the pictures I promised but I solved the problem. A lot of progress has been made since the last time I posted pics so bare with me. This is going to be a long overdue update.

BTW: I lost my thumb nail. Actually I took it off myself. Got tired of waiting for it to fall off. So here goes:

These are pictures of my DIY rock after I removed them from the mold and cleaned them up. There's 14 pieces altogether. Two of them are not shown. I went with the flat look on most of my pieces because to me it looked more natural.

This piece has three tunnels. The one on the right connects to the center tunnel creating a "T" intersection.

In the center picture I placed all the pieces together where I wanted them, placed a plastic bag over it, and made the very top piece. I thought it made it look like it was blended in with the rest of them.

The bottom piece is actually 2 pieces. They were the very first two pieces I showed you with the wooden molds I made so they would go into the tank easier. You can barley see the seam between the two. These pieces are going to be pretty much covered by sand. I made these pieces because it seemed like a waste to take good rock and bury half of it in the sand. It also gives a firm base so there won't be any shifting of the rest of the rocks.

orums.saltwaterfish.com/content/type/61/id/386198/" />

I took a 6ft piece of 1-1/2" PVC and sliced it down the middle ( ) then cut it into 6" pieces. I used them as spacers between the rock pieces to increase the flow of water for a more uniform cure and placed everything in a tub with the strongest power head I had to create circulation between the rocks and filled the tub with water, changing it about once a day. The rock salt that was on the surface was pretty much gone by the next day but I know the internal pieces of salt will take longer. They've been soaking for about a week now while I've been working on the stand. I'll test the PH and salinity this Fathers Day and see how it's doing. I'll post the numbers when I get the results.

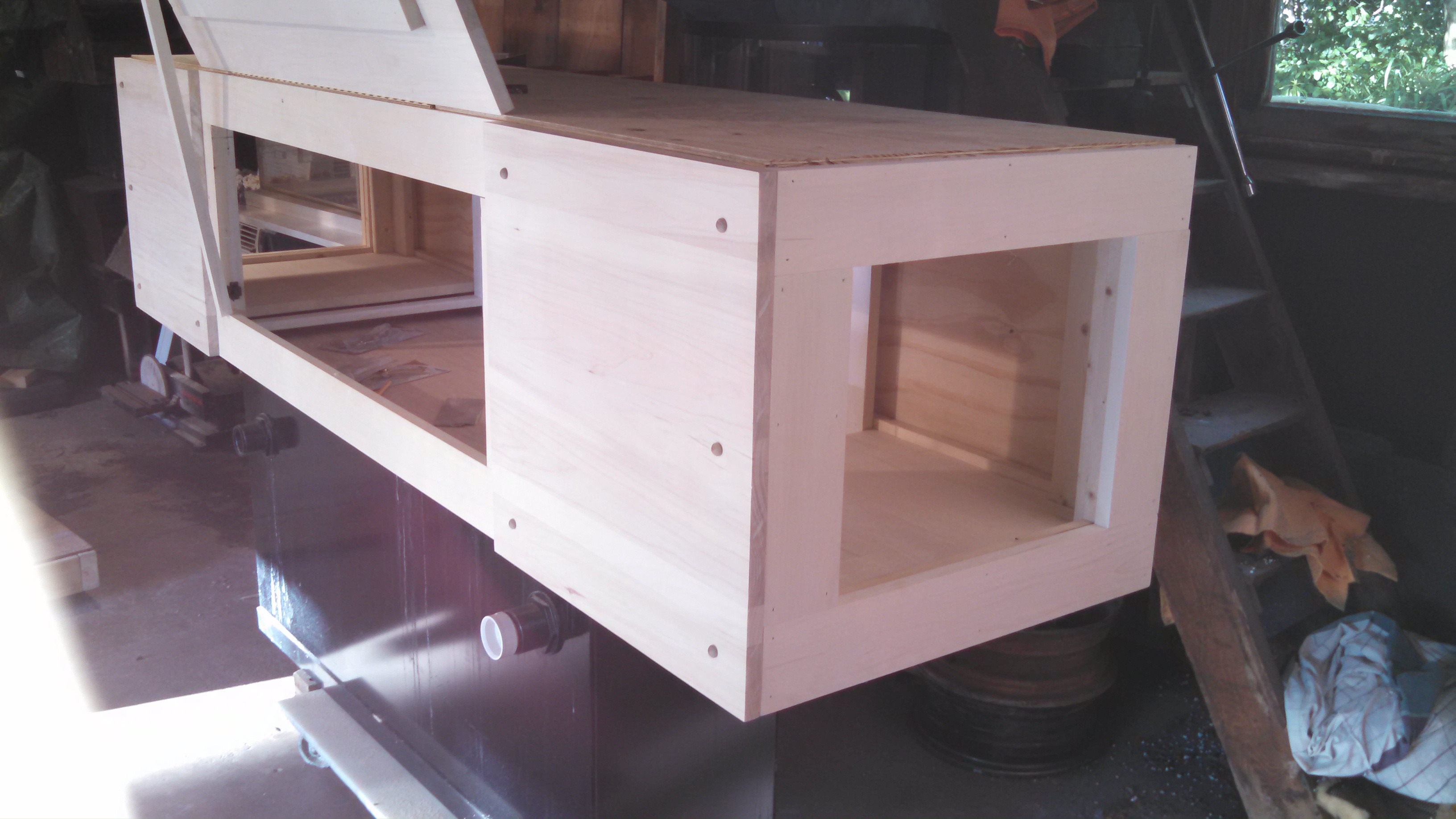

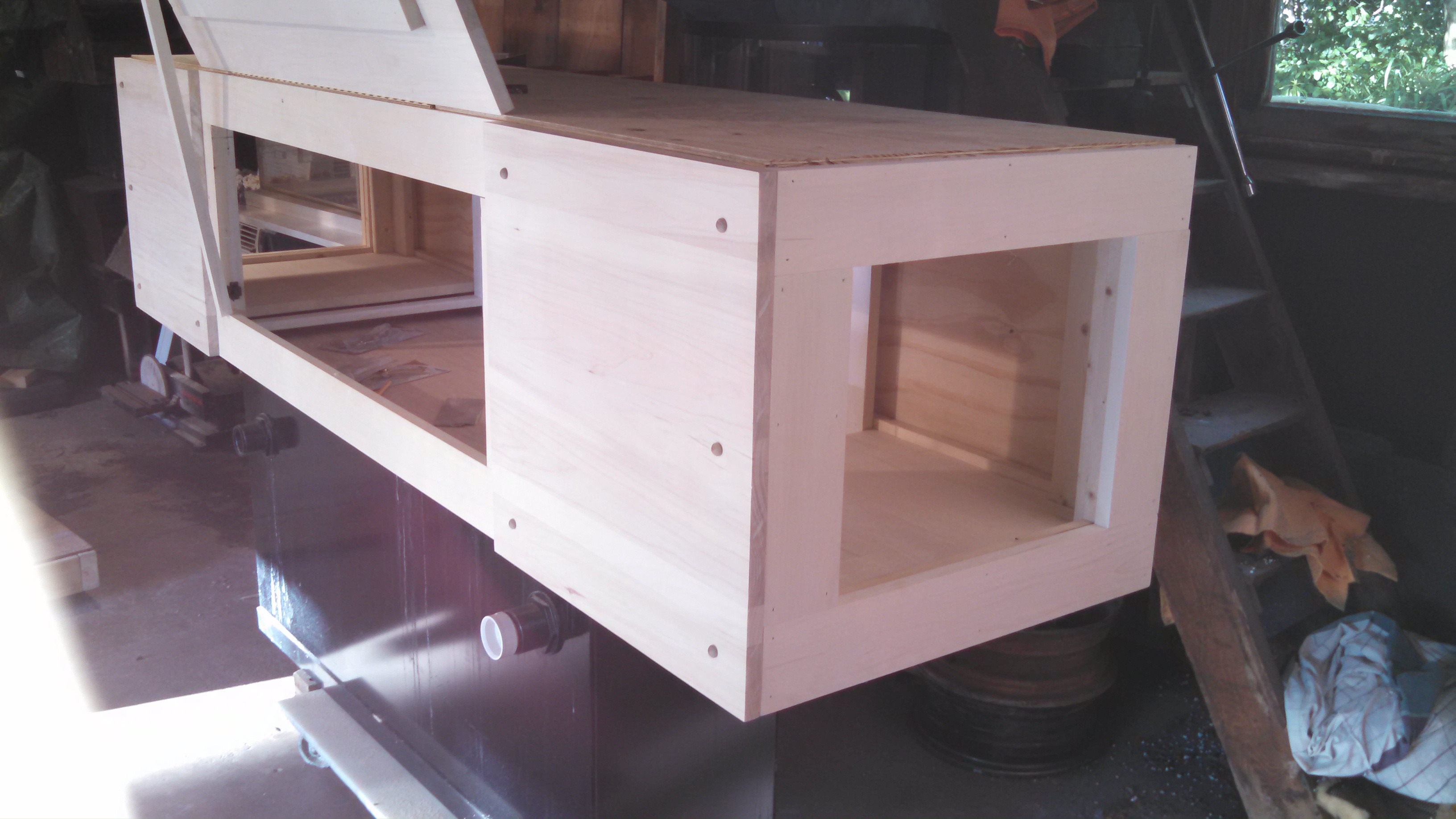

Here's the stand and canopy as I'm just putting the aspen "skin" on the framing.

Here you see the holes I made for the power and tubing lines for the ATO.

The two pieces at either end of the face are easily removed in case I need to take the sump out or do any major repairs. I can also take the back off.

alt="" data-id="386225" data-type="61" src="https://forums.saltwaterfish.com/data/9/9f/9f928932_2014-06-0213.50.44.jpeg

Here's the canopy with all the aspen installed. I remember 2quills saying how the wood swelled on the center swing door of his build which caused it to come off so I put five layers of painters tape between the door and the frame when I installed the piano hinge to give it just a little space for swelling. Then to keep the door from twisting, warping or bowing, I reinforced it with a 1x2 aspen frame. I still haven't decided on what I'm going to use to keep the door open while I work or feed. I tried a couple of friction support hinges for chests but it just wasn't working the way I wanted them to so I took them off. I know what I really need but I'll have to surf the net to find them.

All I need to do now is install the aspen on the towers, trim everything, order the doors (I'm barely getting the stand built with the talents I have so having the doors made is the safest way to go. Besides, there's eight doors to make.), have the doors installed (I really don't want to get them on cockeyed and I have a friend who builds cabinet so I'd rather pay him to install them.), do a lot of tweeking along with a ton of sanding and I'll be ready for stain and poly. After which I'll put it all together with the tank, plump it and start testing the system for leaks and errors. I need to get a punch list together so I don't forget anything.

Well, that's it for now. Any ideas, comments or suggestions, feel free to post them.