I Placed the tank on the stand yesterday and started fitting the plumbing for the overflow to the sump. I figured I would do this before I started sanding, staining and poly.

Here's the variety of pieces I'm using. There's more than what's shown here because I had already started to do the assembly for the plumbing. I started with a wide variety of pieces. I figured I'd rather have too many pieces than not enough or the wrong pieces or pieces I needed and didn't have and had to run to Home Depot to get one. A lot of this is going to end up going back but I figured better safe than sorry.

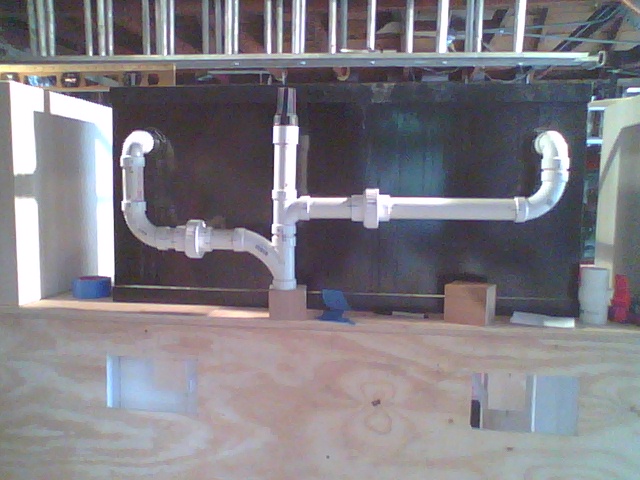

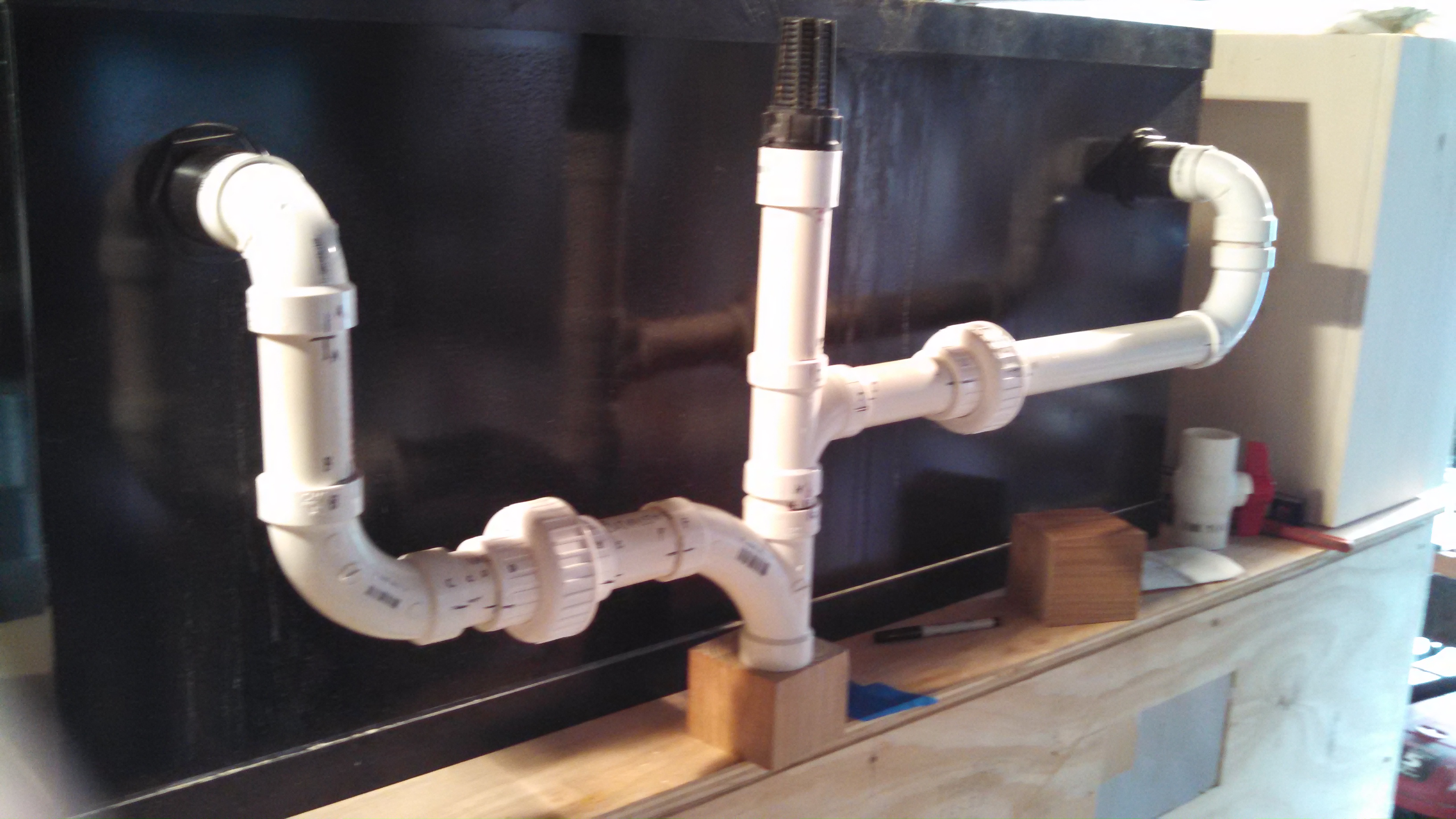

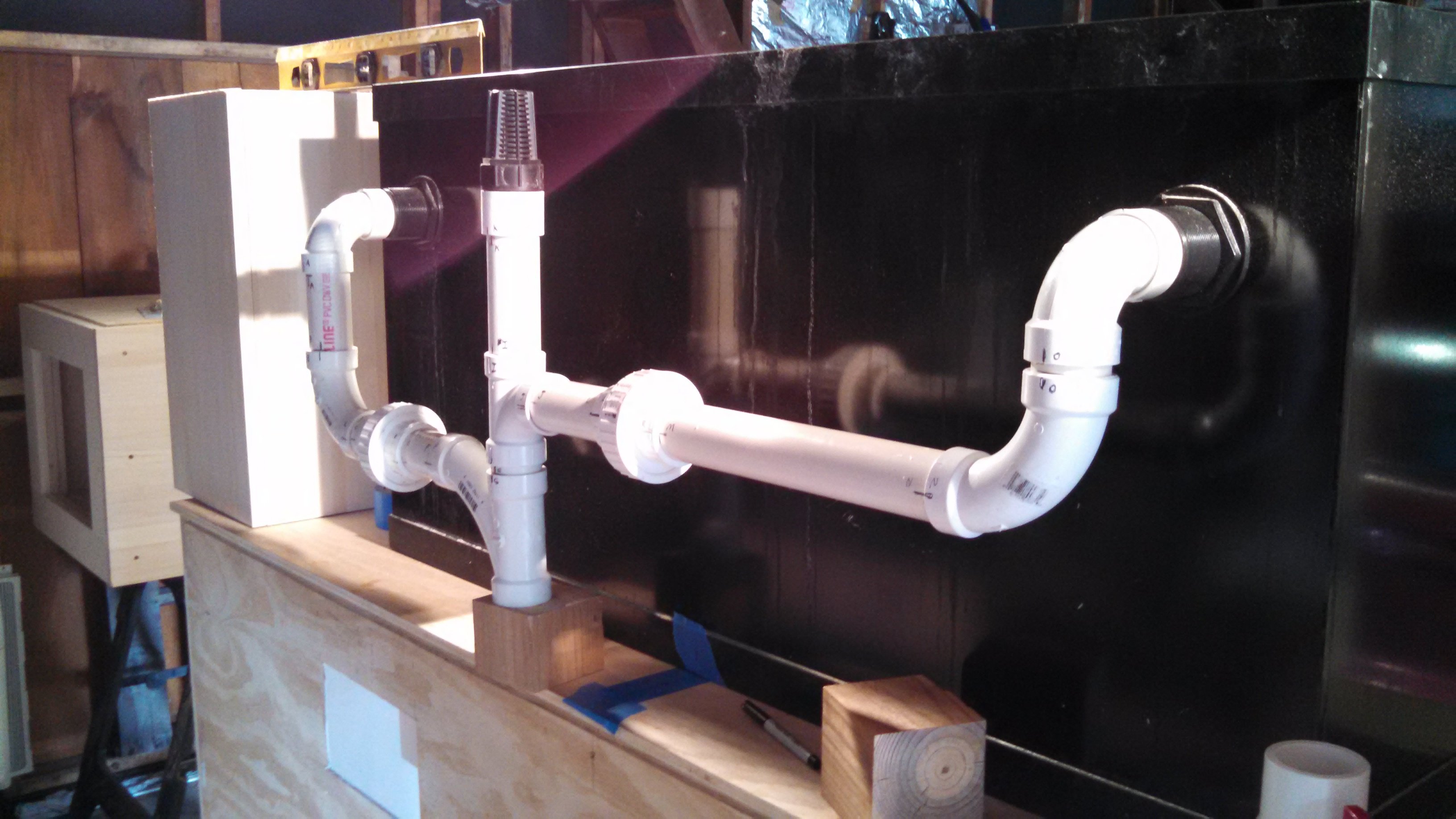

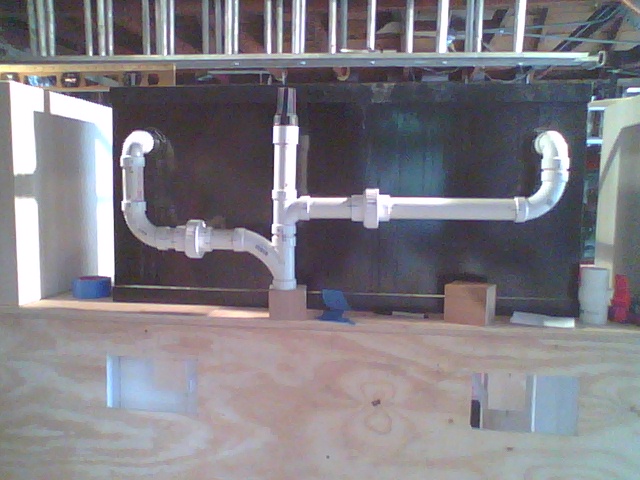

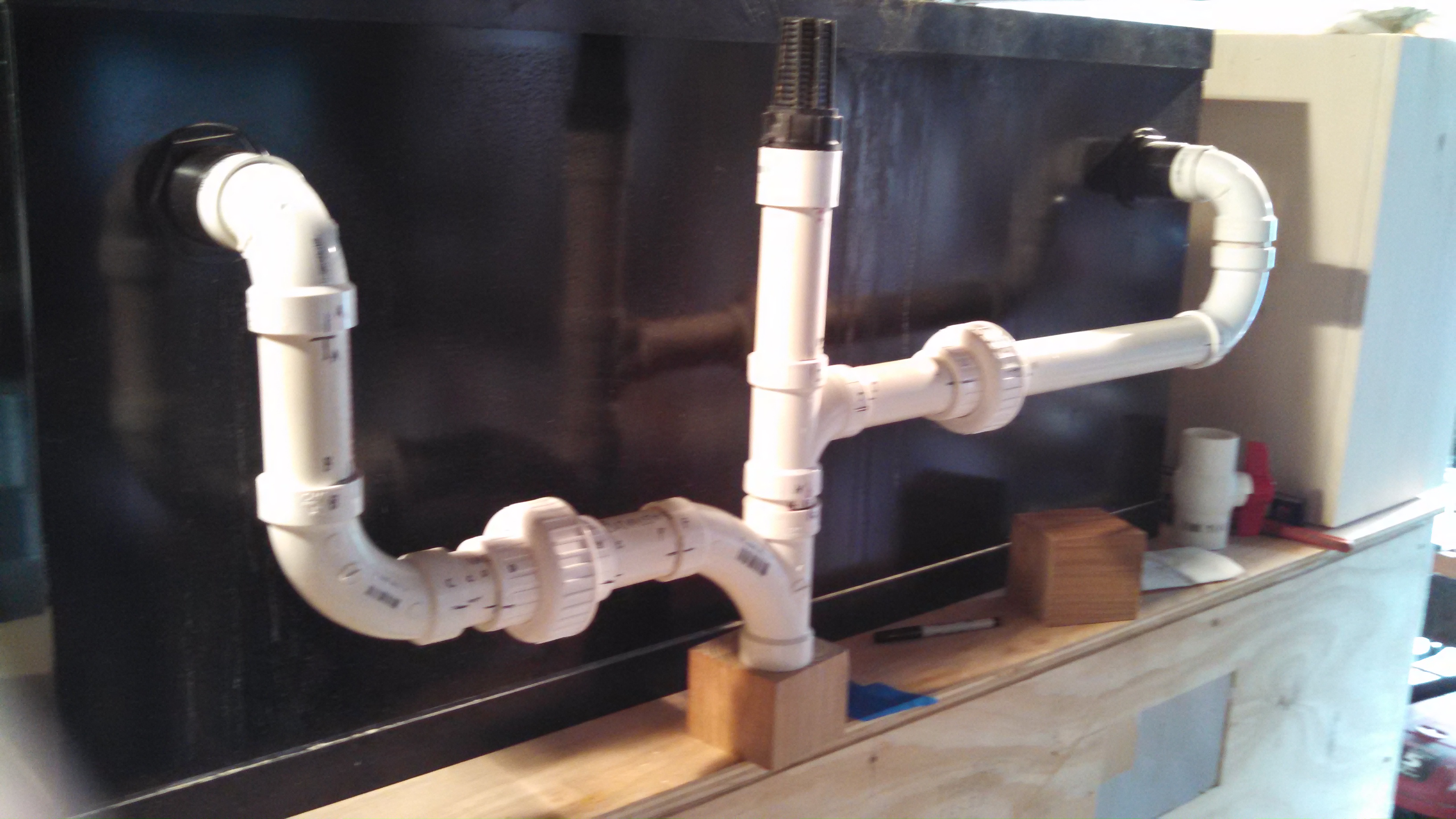

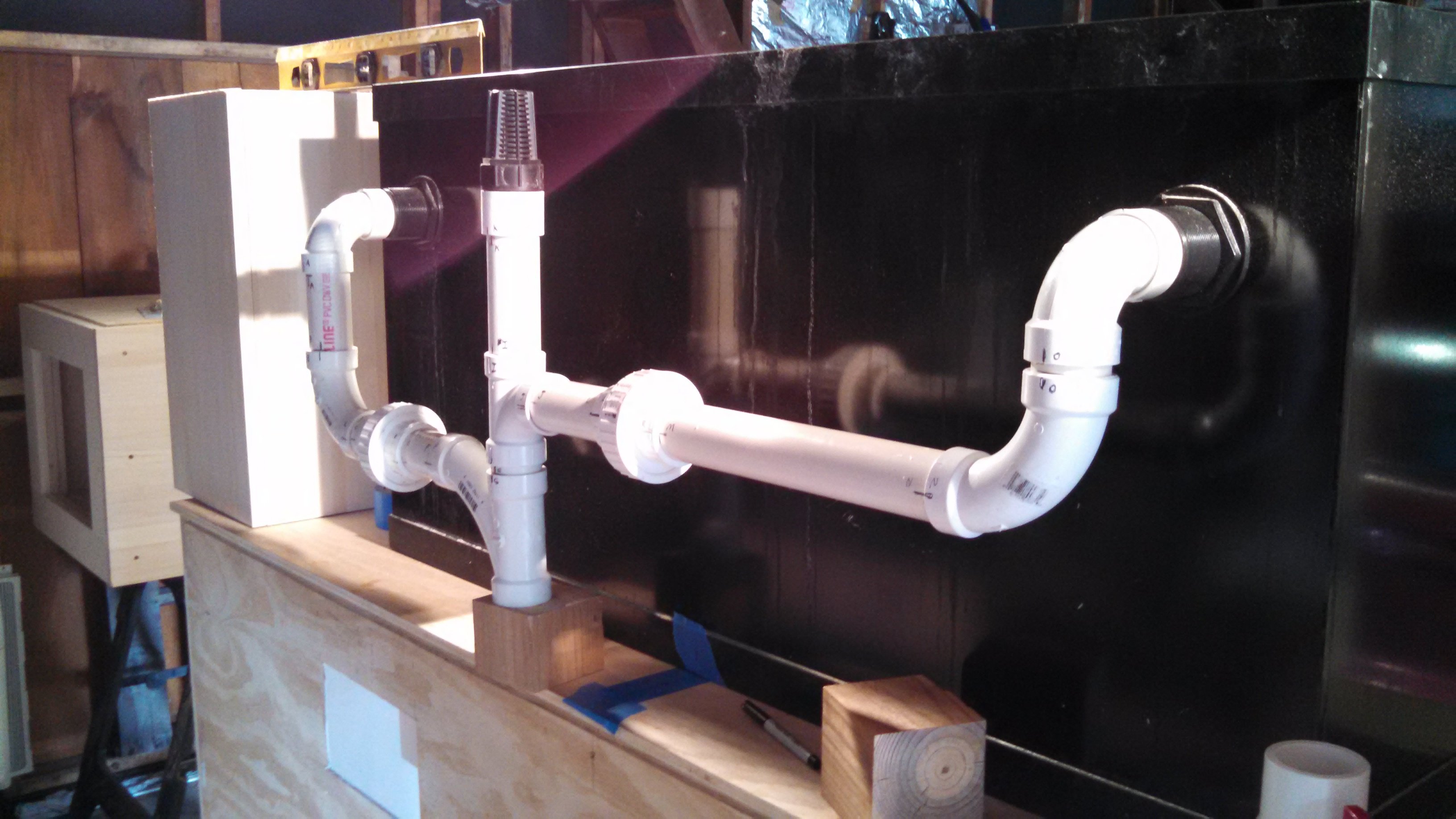

Here's what it looks like so far. I brought each overflow in at different levels so I wouldn't have them crashing into each other at the same point.

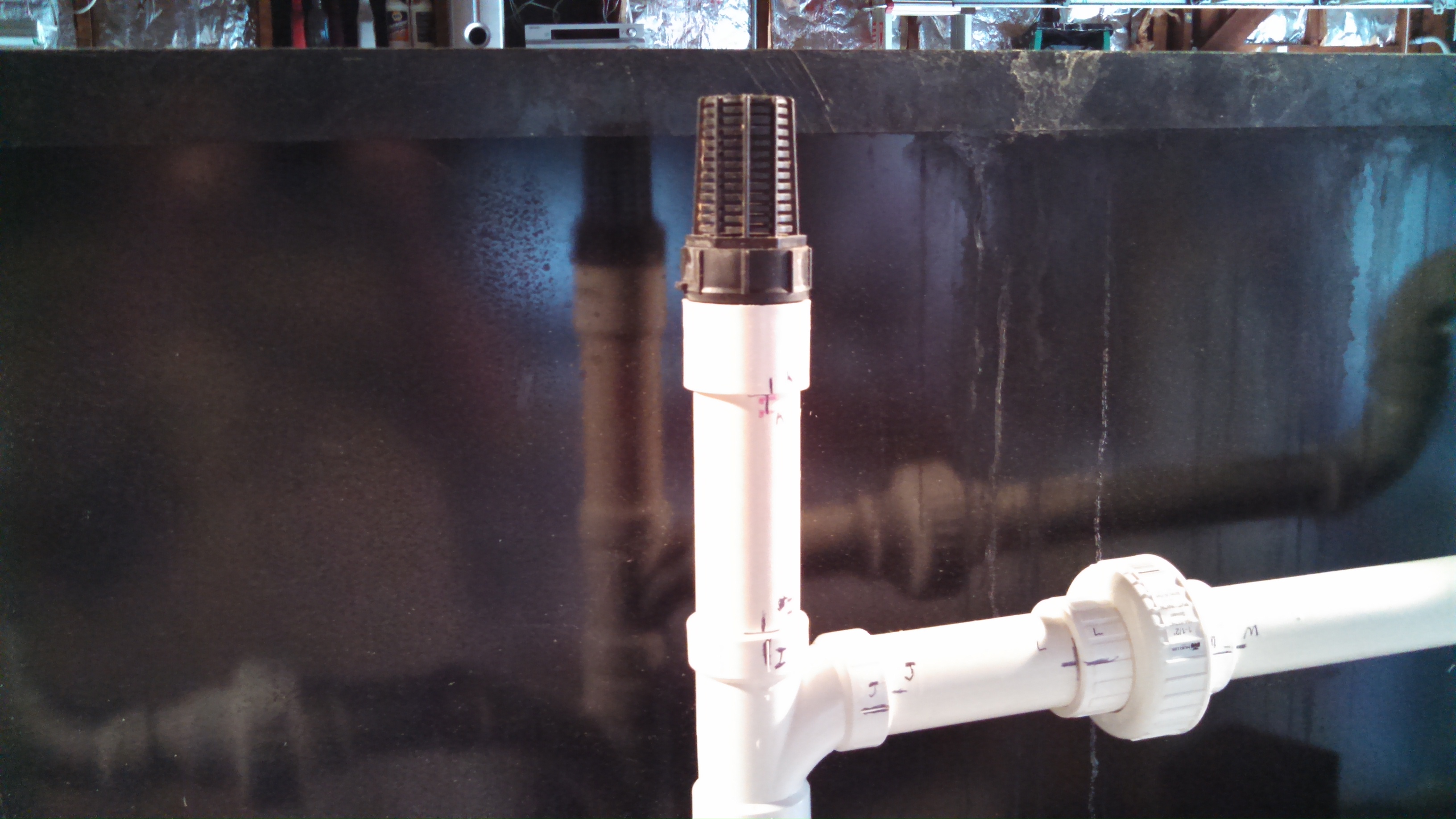

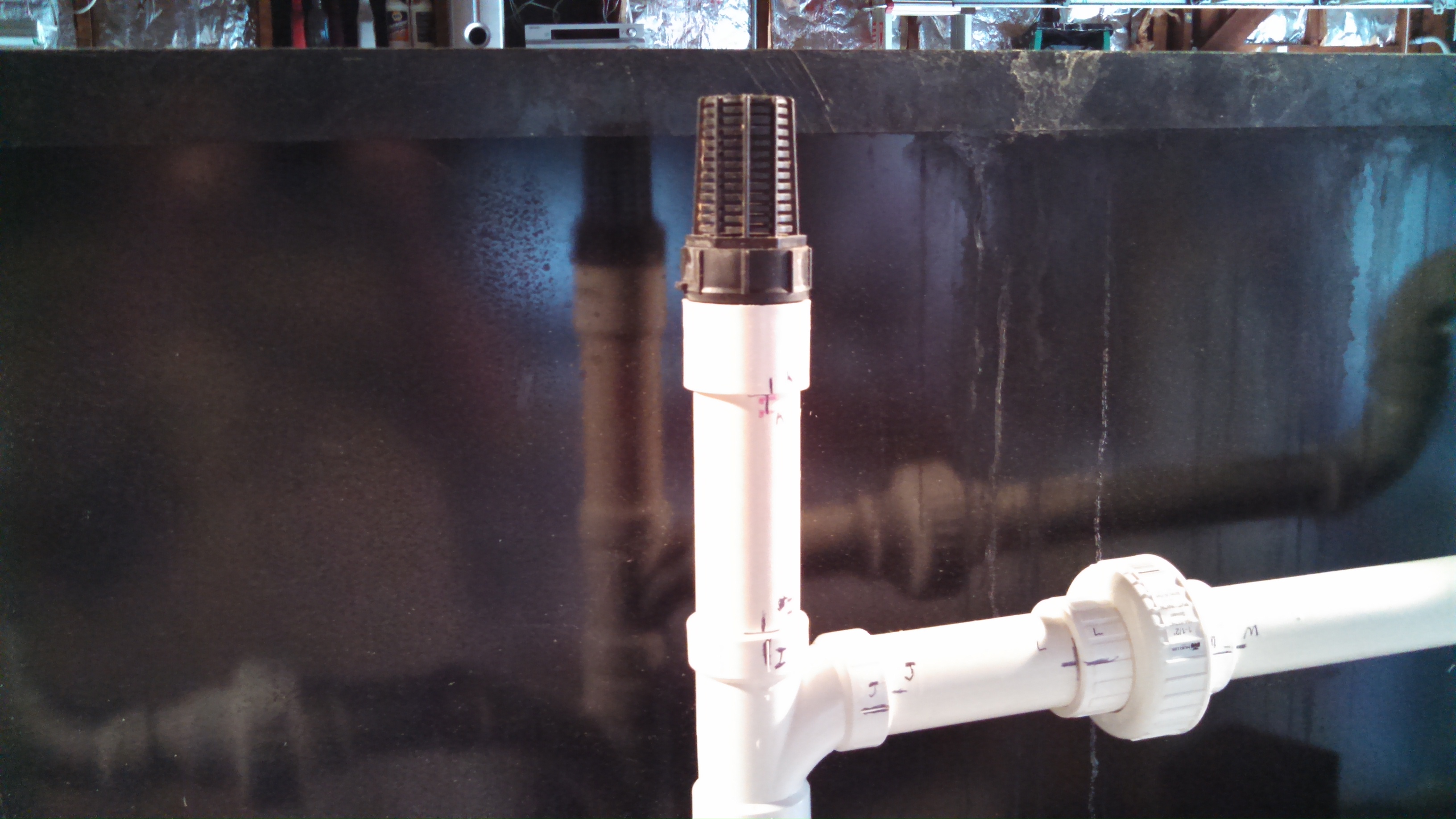

Here's my version of an anti-siphon vent. Crude, but it should work to ease the flow. I just need to lower it a little. If I ever have to remove it for any reason, the canopy would get in the way.

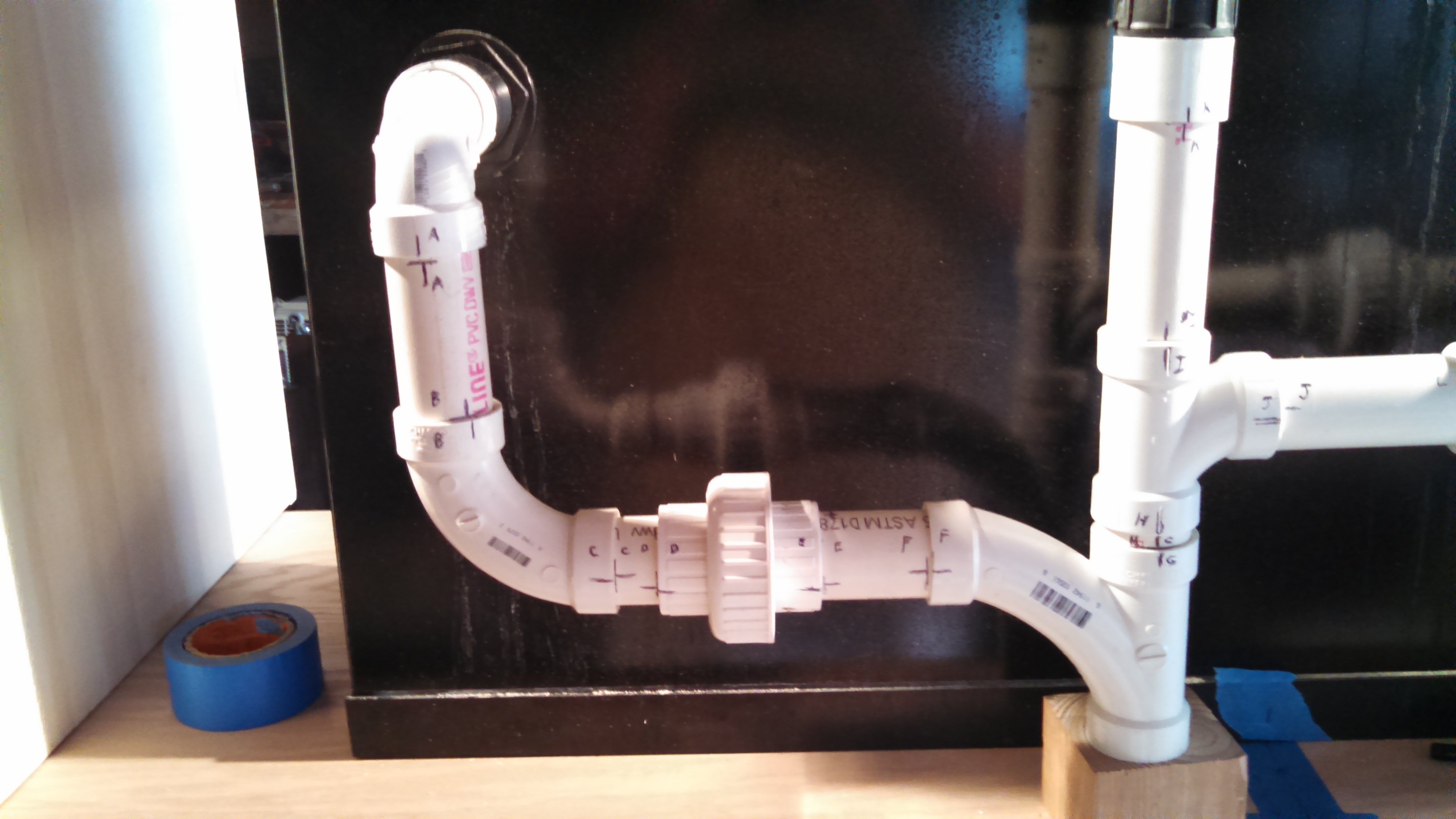

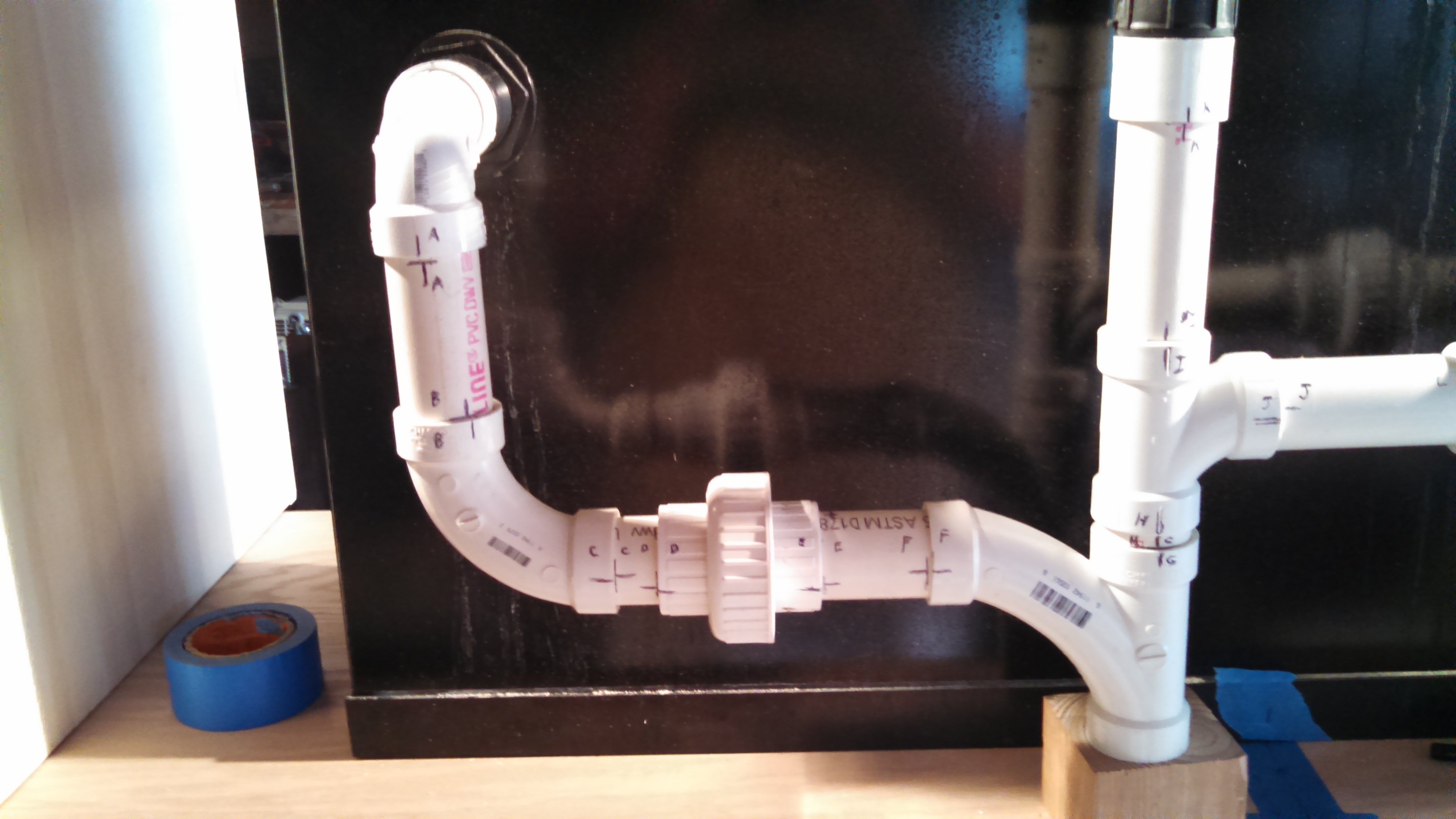

Here's different views of what I've done so far. Any tips, ideas or suggestions, please let me know before I glue it all together.

Each connection is marked for alignment, position and location ( Tab A into slot B ) so I can take it all apart, glue and reassemble it the exact same way it's shown here.

The block of wood between the PVC and the table top is just to keep the pieces lined up and level.

I was going to use three gang valves, one at each overflow and one inside the stand before the drain but they were extremely hard to open and close and I didn't want to take the chance of ever braking a seal trying to turn them off so I opted to just put one inside the stand.

Well, that's it. Let me have your ideas before I glue it all up and move on to the next stage of plumbing, which I'm going to do soon.