Quote:

Originally Posted by

rcdude1990 http:///t/391318/using-a-pump-as-my-a-overflow/20#post_3470536

requires a lot of what?

also guys what if i use the canister tubing as my overflow?

right now the canister filters intake (water from DT to canister), is basically a constant siphon which is located in the middle of the tank... what if i can use this concept and just have a return pump that matches the GPH?

i mean these DIY PVC overflows GPH are rated by the diameter of the PVC right?

so if i use lets say a 1/2" tubing as the intake line, then ill just get a pump that is rated for what ever the 1/2" diameter pvc would be rated...

How do you restart the siphon in case of power outage? The return pump will start up and the overflow wont work. Resulting in the sump being pumped into the tank.

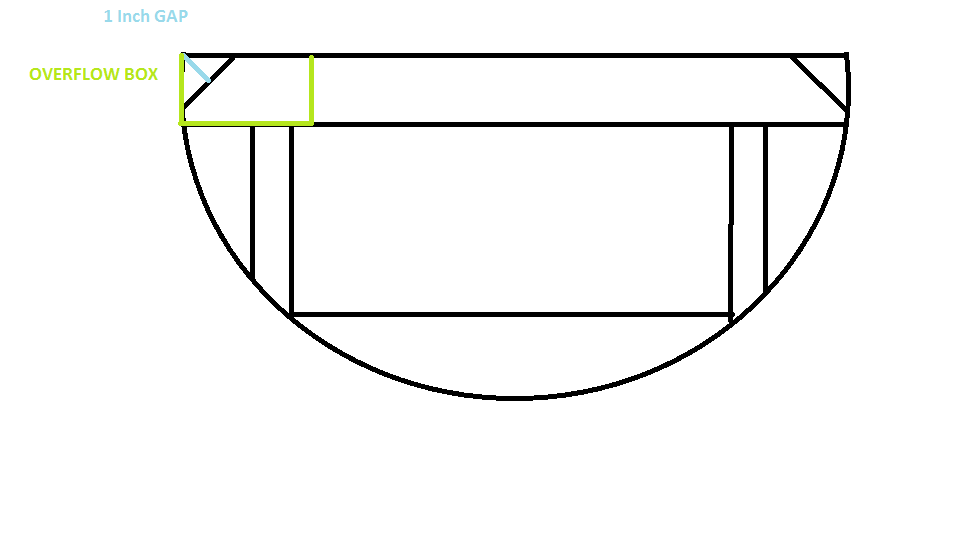

Glasscages make an overflow kit. All you have to do is drill a hole in the back of the tank, which is not that hard. Then silicone the overflow box inside. Wait 48 to 72 hours and leak test. This is probably your best route.