acrylic51

Active Member

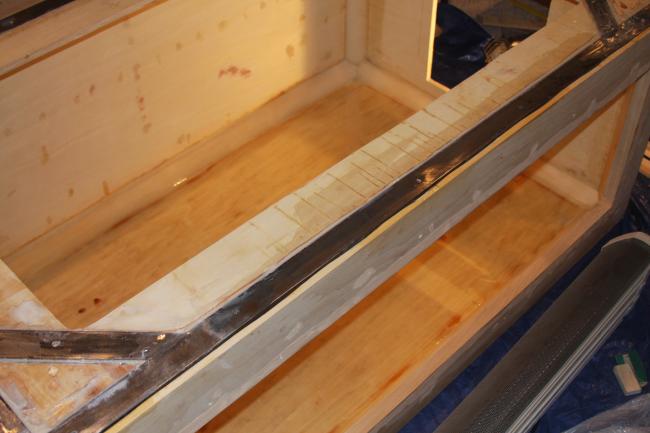

I know what your saying Spanko.....I thought a bit about that afterwards....The 1 problem I see with the snap track something like the transition pieces is that wood itself doesn't hold up very good to repeated taking apart. Haven't ruled it out though. 2Quills suggestions made me start looking alittle further, and getting the bit, I could cut my own into the panel, and with using the T bolts I could actually adjust the tightness of the trim piece to the rest of the skin. I still have to factor into play the finish being applied to the stand, which might affect how the trim actually sits. The skin will be stained, but I'm considering using the Bar Top mirror 2 part epoxy instead of poly??? So the thickness level will be slightly more than what I would achieve with a poly finish......Like I said need the input!!!!!!!