Thanks Spanko.....for the life of me I can remember the name of the post or the orginator of thread....I do vaguely remember the tank was possibly under built for the size of the tank, and I think the tank did have some age to it as well. I guess the heat/crazing issue kind of stuck in my mind, and possibly deterred me from that direction. I've also heard and read some of Ecotech claim on good on thickness to 3/4", but then I started hearing about issues of the units staying together and falling apart. For that kind of cash; I'm not really looking to deal with what if's??????

Honestly it I don't see how EcoTech can say professionally built.....There are major companies that suggest against their uses and others, and then you have smaller companies and depending who you talk to reputable or not.....Just like the company in Virginia that built that sweet tank for the guy, only to have it come apart at the seam, and the company didn't want to stand behind their work.....Alot of acrylics people/shops will tell you that all acrylic is the same, and if you actually take the time to look at their properties, there is a difference, and difference in qualities of acrylic out there.....So I find their claims questionable???????

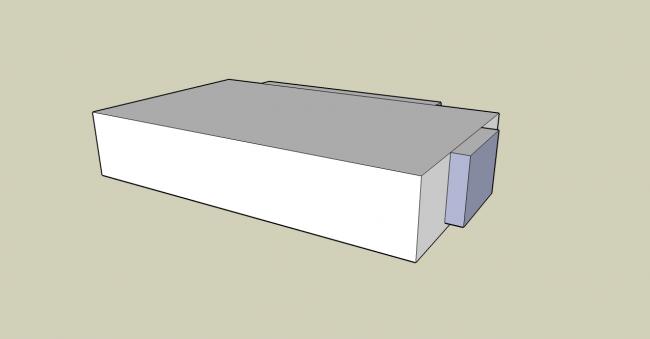

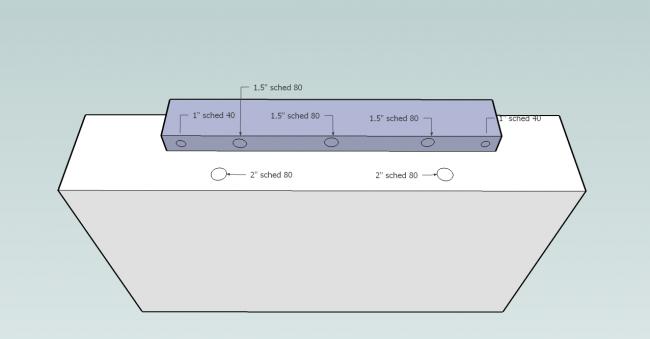

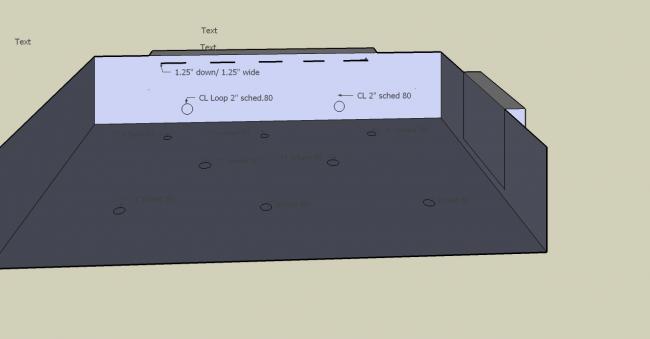

I do understand fully when they talk about construction quality.....Proper panel sizing and bracing. Some people might opt to go for a thinner panel on their build to shave a couple bucks. Sizing of panels can be debateable depending who you talk to as well. I know with all the little add ons and reinforcements through conversations with good builders 3/4" will be more than enough, but have honestly considered stepping up to 1" material???? Maybe crazy, but safety......

Since were on that roll, I totally haven't decided on glass vs. acrylic. I do know the pros and cons of both, and it comes down to price....I've checked locally and the glass shops aren't to helpful IMHO....Their prices are outrageous, and I already know that if I go glass the panels will have to be Starphire or LowE glass. My 240 is done in LowE and I will never have another tank done with regular glass. Alot of people will debate, but there is a difference when you put the 2 side by side. With that said having the glass shipped in racks up the expense. Bottom line going to thicker 1" Spartech acrylic would be cheaper.

Alot of people will debate the issue of the acrylic scratching to easy....Another area still not totally decided at this point in the game is if the tank will be bare bottom (BB) or I've been contemplating doing a faux sand bed. Meaning since I'm already pouring epoxy, why not pour an additional coat and before the epoxy sets up sift sand into the wet epoxy and let it harden and do this until I'm satisfied with the coverage???? This way I could still get the look of the sandbed, but wouldn't have to deal with blowing sand with having tons of water movement....

With that being said I have a few questions or options, I'd really love to hear everyones input on......come on guys everyone has gotta have a preference or choice and want to hear exactly why they'd go that route. With that said here are my proposed questions to you all.

1. Glass or Acrylic ?

2. Bare Bottom ? Why?

3. Faux Sand Bed ? Why?

4. SSB (Shallow Sand Bed) Why?

Let's hear your suggestions need the input

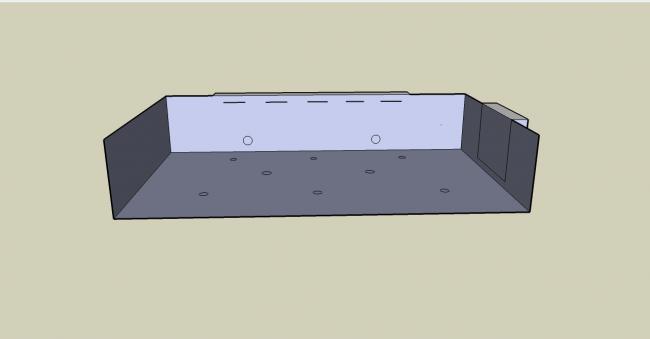

I'm with you on still being old fashion and drawing everything out by hand, but it makes it alot easier to draw things up and be able to just click a couple times and get tons of feedback or critiques from others.

I'm with you on still being old fashion and drawing everything out by hand, but it makes it alot easier to draw things up and be able to just click a couple times and get tons of feedback or critiques from others.