415 Gallon Plywood Tank Build

- Thread starter acrylic51

- Start date

acrylic51

Active Member

Quote:

Originally Posted by Desertdawg http:///forum/thread/376802/415-gallon-plywood-tank-build/880#post_3379788

Yeah, what he said!

and bonus points for pictures...

Quote:

Originally Posted by 1Snapple http:///forum/thread/376802/415-gallon-plywood-tank-build/880#post_3379620

Update?

Sorry guys, been slacking!!!!!!

Originally Posted by Desertdawg http:///forum/thread/376802/415-gallon-plywood-tank-build/880#post_3379788

Yeah, what he said!

and bonus points for pictures...

Quote:

Originally Posted by 1Snapple http:///forum/thread/376802/415-gallon-plywood-tank-build/880#post_3379620

Update?

Sorry guys, been slacking!!!!!!

2quills

Well-Known Member

acrylic51

Active Member

I know you guys have been waiting for updates......You see me over on Corey's thread and a bit slipped out, but Corey is always there to hear my crazy idiotic ideas I have brewing it seems all hours of the day........

Thanks Corey!!!!!!

Thanks Corey!!!!!!

With that much said there will be a major update hopefully tomorrow evening, but like I had mentioned worse case Friday......Trust me I'm dying to get started as well. I've been tossing around a lot of stuff on different projects, and things are falling into place. Work schedule hasn't gotten much better, but working around that though.....As I had mentioned briefly in Corey's thread or maybe I didn't. That might have been in 1 of are many conversations over the phone, but I was telling Corey about a flow scheme inside a tank!!!!! It seems to me a lot of time there's not really much thought or consideration as to where we place water returns or PH's in our systems, but I just happen to stumble upon these threads and info and thought it was rather intriguing to say the least.......Hopefully you guys will take a gander and check out the links, and maybe it will spark something. This is where I know I had mentioned in Corey's thread today about getting a lot of input and ideas, when I give the major update shortly, but this is 1 area that will be highly looked at.

Here's the links that might interest some of you......Enjoy!!!!

http://www.reef-eden.net/2006_reef_9.htm

** This link has to do with water flow...**

http://www.reefcentral.com/forums/showthread.php?t=1563053&highlight=rod+gyre

** This link is what initially caught my eye causing me to dig a little deeper behind the scenes....Truly a stunning setup IMO.**

With that much said there will be a major update hopefully tomorrow evening, but like I had mentioned worse case Friday......Trust me I'm dying to get started as well. I've been tossing around a lot of stuff on different projects, and things are falling into place. Work schedule hasn't gotten much better, but working around that though.....As I had mentioned briefly in Corey's thread or maybe I didn't. That might have been in 1 of are many conversations over the phone, but I was telling Corey about a flow scheme inside a tank!!!!! It seems to me a lot of time there's not really much thought or consideration as to where we place water returns or PH's in our systems, but I just happen to stumble upon these threads and info and thought it was rather intriguing to say the least.......Hopefully you guys will take a gander and check out the links, and maybe it will spark something. This is where I know I had mentioned in Corey's thread today about getting a lot of input and ideas, when I give the major update shortly, but this is 1 area that will be highly looked at.

Here's the links that might interest some of you......Enjoy!!!!

http://www.reef-eden.net/2006_reef_9.htm

** This link has to do with water flow...**

http://www.reefcentral.com/forums/showthread.php?t=1563053&highlight=rod+gyre

** This link is what initially caught my eye causing me to dig a little deeper behind the scenes....Truly a stunning setup IMO.**

2quills

Well-Known Member

Those are some interesting flow patterns in the links there. I wonder how much of the actual pattern the one guy would be getting with the wave type simulation of rolling current with the rock structures in the tank? Personally I wouldn't be terribly crazy about seeing the 4 elbows in the front bottom of the tank in order to try and achieve it. But creatively speaking it could be possible to disguise them I would think.

I like the idea of the tidal simulation. I've considered something similar in the past utilizing powerheads. Thinking it would easily be more practical to achieve something along those for sure. Just wondering how much all of this more specific type flow would be beneficial over some standard random/crashing flow. This I don't know.

I like the idea of the tidal simulation. I've considered something similar in the past utilizing powerheads. Thinking it would easily be more practical to achieve something along those for sure. Just wondering how much all of this more specific type flow would be beneficial over some standard random/crashing flow. This I don't know.

acrylic51

Active Member

I just thought it was rather interesting......I love the idea of the 4 bulkheads in the front, and as you said could think of a way or 2 to possibly hide them.....I don't necessarily think it would have to be done in that fashion, but achieving that circular flow and then the tidal flow would be a lot easier to achieve. I think I mentioned it more for the mere fact it seems that a lot of people just seem to aim their PH's at their coral vs getting a good flow pattern going inside the aquarium....I think a combination of both patterns shown in the link would created that random/crashing flow.......I think a lot comes down to timing of the pumps and such, but could definitely create that pattern. That is where I believe the OM's would/could come into play or a VFD pump. I had mentioned the VFD pumps a long time back.

I actually have thought a bit about those 4 bulkheads across the front of the tank, a bit, and I'll have to share my idea shortly!!!!!

Another option would be to hide those bulkheads more towards the middle/back of the bottom of the tank and hide them with rock work, and fire them towards the front of the tank. Again rock placement would be key though......

Another option would be to hide those bulkheads more towards the middle/back of the bottom of the tank and hide them with rock work, and fire them towards the front of the tank. Again rock placement would be key though......

I actually have thought a bit about those 4 bulkheads across the front of the tank, a bit, and I'll have to share my idea shortly!!!!!

acrylic51

Active Member

Actually Corey your thinking is exactly like Paul the owner of OM.....his layout or design would be to have the bulkheads/water return from the sump firing from the backwall by the overflow downward towards the back bottom of the tank; forcing the water down and under and then in turn it would be forced upwards and back towards the overflow.....

sweatervest13

Active Member

I enjoyed the links. Good reading. The guy in Australia with all the holes in the bottom of the tank, that was crazy. He was able to hide the bulkheads and fittings with his rock real well. I would imagine that if you were to go with the four elbows in the front of the tank you could hide with small rock. It might look weird just to have four rocks just chillin in the front of the tank. You might be able to have a rock line in front then a small gap with sand then your big rock structure. Just an idea.

Can't wait to see what you got up your sleeve.

Can't wait to see what you got up your sleeve.

acrylic51

Active Member

Morning guys & gals!!!!!!!

Figured I'd have to keep my promise a far as an update, and as some of you kinda know it's going to be some major changes.......

Figured I'd have to keep my promise a far as an update, and as some of you kinda know it's going to be some major changes.......

With the change of position(job) with UPS Freight, time has been a precious commodity at times.....After a lot of thought and pondering and cigarettes I've decided to put the Plywood build on "hold" and change course of direction. Maybe someday finishing off the plywood build, but as most of you know these type builds aren't typical, and I'm very anal about anything I work on and steady work time on the build isn't getting my steady attention, and the wife is anxious to get her family room back, and I think she's is wanting a tank back up as well.........

With the change of position(job) with UPS Freight, time has been a precious commodity at times.....After a lot of thought and pondering and cigarettes I've decided to put the Plywood build on "hold" and change course of direction. Maybe someday finishing off the plywood build, but as most of you know these type builds aren't typical, and I'm very anal about anything I work on and steady work time on the build isn't getting my steady attention, and the wife is anxious to get her family room back, and I think she's is wanting a tank back up as well.........

I sat down with my wife a couple weeks ago and we started kicking around ideas, and she suggested I go back to my original plan with the tank build and that was to build the tank out of acrylic.....As most of us "married" folks know you should/usually follow the others leads on things, and after 15yrs I realized "damn.....she's never steered me wrong"!!!!! So immediately after our conversation I was back in the family room remeasuring and had my buddies Tom & Matt from Grims Plastic on the phone....Now you guys have to realize I have a very long working relationship with these guys, and another big plus factor is my wife grew up in the same neighborhood and went to school with these guys!!!!!! These guys are incredible....They readily open their shop up to me anytime I need, any questions, or scrap wanting to practice or just play, they are there and accomodating.

Needless to say after a couple phone calls and measuring and figuring; I finally gave Tom the go ahead to order the material......I had called a couple other places out of town, and none could get me the choice acrylic I was looking for.....I had 1 demand that the acrylic be Polycast.....That is off of James from Envision recommendation.....He is probably the finest acrylic builder around, and when you see his work and talk to him as to why that is his material of choice you'll understand and follow.....Trust me Polycast isn't cheap, but the results are impecable......Tom ordered the material on a Tuesday, and had it in house in a couple days, and I knew Tom was headed to the beach for vacation which only left Matt in the shop.....Matt has a bad arm, so handling that size material is no easy task.....Needless to say Tom gave up an extra beach day to make sure that they got the material cut and ready for me for my scheduled date, but actually a day earlier.....A big Thanks Tom & Matt!!!!!!!!

So.......The "NEW" tank will be built with Polycast cast acrylic.....The tank will be 1" thick acrylic all the way around......I actually wanted to use 1 1/2" and James kind of chuckled and said way overkill, but loved the idea of the tank being so thick.....I now thank God I headed is words......1" is a bear for me to handle the panels, couldn't imagine 1 1/2" material.....The tank dimensions wil be 72"Lx29"Hx48"W......All panels will be 1" thick. The tank will be a lot similar to the plywood tank, with a few changes......The new tank will still be euro braced and no cross bracing. After talking with James; the euro bracing will be 6" wide which will make the tank very tight; no bow......If you were standing looking at the tank the back panel and right side panel will be black acrylic.....(mind you the black acrylic is a lot more expensive than the clear, but I had to do it my way.....)

One of the major changes is that I'm considering moving the overflow box from the back wall (as planned on the plywood build) to the right end of the tank......I'm considering this change due to a conversation and 'my voices in m head" that if I'm going to use an external wave box with the overflow on the back wall and wavebox on the far end; would I not loose some of my wave generation with this configuration? What I'm saying if the water is forced from the right side of the tank to the left side; wouldn't on the return action of the wave be lost because it would hit the overflow opening and therefore drop off the wave return/action to the right end of the tank?

My logic or thinking that putting the external overflow on the end of the tank and wave boxes mounted on both sides of the overflow; the water would be forced again to the left side of the tank, hit the left end and be forced to return to the right end of the tank; thereby keeping the full wave motion and at that point upon returning back to the right end being forced into the overflow?????

My logic or thinking that putting the external overflow on the end of the tank and wave boxes mounted on both sides of the overflow; the water would be forced again to the left side of the tank, hit the left end and be forced to return to the right end of the tank; thereby keeping the full wave motion and at that point upon returning back to the right end being forced into the overflow?????

Would love to here everyones input and thinking/logic???? Don't be shy!!!!!! Also want to hear everyones take on overflow teeth vs a straight edge/slot on the overflow???? Meaning the overflow would just be an opening in the panel vs your more traditional tooth designed overflow box....

Would love to here everyones input and thinking/logic???? Don't be shy!!!!!! Also want to hear everyones take on overflow teeth vs a straight edge/slot on the overflow???? Meaning the overflow would just be an opening in the panel vs your more traditional tooth designed overflow box....

I will have to get some pics of the acrylic sitting in the garage in a bit, just to give you guys an idea on size of the panels.....Still have to get to Lowes to pick up material for making my new jigs for the build.....I've been practicing the past 2 days using the pin glue method......I want to master the technique before touching the real panels.....

There are other changes coming on the build, but I want to take each proposed change step by step so nothing gets lost.....

This is my original design with the overflow on the right side of the tank.....(Disregard) the overflow on the back of the tank.....The external wave boxes would flank the overflow on both the left and right side???? Thoughts???? Ideas??????

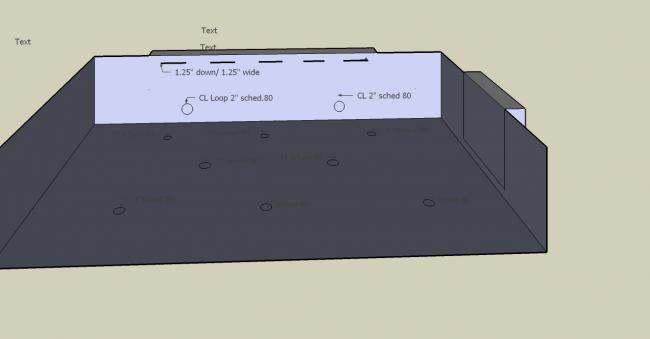

Sorry for the poor drawing.....Even though this shows the overflow on the back of the tank, I'm using the pic to show or reference what I mean slots vs the traditional overflow teeth design. What would you guys do? Pros and Cons??? I can tell you not to concerned about errant fish making their way into the overflow, and overflow teeth also cut down surfacing skimming and there's a factor of noise as well, but lets here your thoughts and ideas??????

I sat down with my wife a couple weeks ago and we started kicking around ideas, and she suggested I go back to my original plan with the tank build and that was to build the tank out of acrylic.....As most of us "married" folks know you should/usually follow the others leads on things, and after 15yrs I realized "damn.....she's never steered me wrong"!!!!! So immediately after our conversation I was back in the family room remeasuring and had my buddies Tom & Matt from Grims Plastic on the phone....Now you guys have to realize I have a very long working relationship with these guys, and another big plus factor is my wife grew up in the same neighborhood and went to school with these guys!!!!!! These guys are incredible....They readily open their shop up to me anytime I need, any questions, or scrap wanting to practice or just play, they are there and accomodating.

Needless to say after a couple phone calls and measuring and figuring; I finally gave Tom the go ahead to order the material......I had called a couple other places out of town, and none could get me the choice acrylic I was looking for.....I had 1 demand that the acrylic be Polycast.....That is off of James from Envision recommendation.....He is probably the finest acrylic builder around, and when you see his work and talk to him as to why that is his material of choice you'll understand and follow.....Trust me Polycast isn't cheap, but the results are impecable......Tom ordered the material on a Tuesday, and had it in house in a couple days, and I knew Tom was headed to the beach for vacation which only left Matt in the shop.....Matt has a bad arm, so handling that size material is no easy task.....Needless to say Tom gave up an extra beach day to make sure that they got the material cut and ready for me for my scheduled date, but actually a day earlier.....A big Thanks Tom & Matt!!!!!!!!

So.......The "NEW" tank will be built with Polycast cast acrylic.....The tank will be 1" thick acrylic all the way around......I actually wanted to use 1 1/2" and James kind of chuckled and said way overkill, but loved the idea of the tank being so thick.....I now thank God I headed is words......1" is a bear for me to handle the panels, couldn't imagine 1 1/2" material.....The tank dimensions wil be 72"Lx29"Hx48"W......All panels will be 1" thick. The tank will be a lot similar to the plywood tank, with a few changes......The new tank will still be euro braced and no cross bracing. After talking with James; the euro bracing will be 6" wide which will make the tank very tight; no bow......If you were standing looking at the tank the back panel and right side panel will be black acrylic.....(mind you the black acrylic is a lot more expensive than the clear, but I had to do it my way.....)

One of the major changes is that I'm considering moving the overflow box from the back wall (as planned on the plywood build) to the right end of the tank......I'm considering this change due to a conversation and 'my voices in m head" that if I'm going to use an external wave box with the overflow on the back wall and wavebox on the far end; would I not loose some of my wave generation with this configuration? What I'm saying if the water is forced from the right side of the tank to the left side; wouldn't on the return action of the wave be lost because it would hit the overflow opening and therefore drop off the wave return/action to the right end of the tank?

I will have to get some pics of the acrylic sitting in the garage in a bit, just to give you guys an idea on size of the panels.....Still have to get to Lowes to pick up material for making my new jigs for the build.....I've been practicing the past 2 days using the pin glue method......I want to master the technique before touching the real panels.....

There are other changes coming on the build, but I want to take each proposed change step by step so nothing gets lost.....

This is my original design with the overflow on the right side of the tank.....(Disregard) the overflow on the back of the tank.....The external wave boxes would flank the overflow on both the left and right side???? Thoughts???? Ideas??????

Sorry for the poor drawing.....Even though this shows the overflow on the back of the tank, I'm using the pic to show or reference what I mean slots vs the traditional overflow teeth design. What would you guys do? Pros and Cons??? I can tell you not to concerned about errant fish making their way into the overflow, and overflow teeth also cut down surfacing skimming and there's a factor of noise as well, but lets here your thoughts and ideas??????

sweatervest13

Active Member

WOW. That is some BIG news. I like it!!!

I have learned to listen to the wife, she just knows better most of the time. LOL.

433G?? or is it minus one inch all around? The back and right panel where the overflow is are going to be black? That should look nice and clean. Are the holes on the bottom of the tank in the last drawing for the CL? I think you are right with the wave boxes flanking the overflow. But with the CL how would that react? I am no flow expert or anything close. LOL But would it work togheher with the CL or kind of against it? Depending on the flow pattern you were trying to achieve with the CL (per your links yesterday with the Australian guy and then the 4 45 degree elbow on the bottom front guy) I thought you were creating a wave like motion with that? But the more I think about it the more water movement the better. I was just really intrigued buy the 2 or more CL's working at different times to create a few different types of flow.

I think this is going to be an awesome build!!! Are you going to start a new thread for it?

I have learned to listen to the wife, she just knows better most of the time. LOL.

433G?? or is it minus one inch all around? The back and right panel where the overflow is are going to be black? That should look nice and clean. Are the holes on the bottom of the tank in the last drawing for the CL? I think you are right with the wave boxes flanking the overflow. But with the CL how would that react? I am no flow expert or anything close. LOL But would it work togheher with the CL or kind of against it? Depending on the flow pattern you were trying to achieve with the CL (per your links yesterday with the Australian guy and then the 4 45 degree elbow on the bottom front guy) I thought you were creating a wave like motion with that? But the more I think about it the more water movement the better. I was just really intrigued buy the 2 or more CL's working at different times to create a few different types of flow.

I think this is going to be an awesome build!!! Are you going to start a new thread for it?

acrylic51

Active Member

Quote:

Originally Posted by 2Quills http:///forum/thread/376802/415-gallon-plywood-tank-build/900#post_3399673

It's gonna be a heavy son of a gun. Are you still thinking of building it in the garage and carrying it down stairs? I think I like the changes to the overflow idea.

Funny!!!!! I know I said that was the original plan, but with my back, and just getting the top and bottom pieces off the truck by myself yesterday afternoon in 100 degree weather.H$LL NO!!!!!!!! I could probably get away with putting the walls together, and then moving it inside for the top and bottom, but with the heat and not seeing a break in the heat till possibly mid week, I'm really leaning towards inside....The only bad thing is when it comes time to router everything flush, the mess. You know what I mean by the mess. I guess I could try attaching the suction line to the shop vac that I bought, that I've never used a shot as well???? I'm actually liking the overflow on the end as well, but leads me to the question as to should it be external or internal?

Funny!!!!! I know I said that was the original plan, but with my back, and just getting the top and bottom pieces off the truck by myself yesterday afternoon in 100 degree weather.H$LL NO!!!!!!!! I could probably get away with putting the walls together, and then moving it inside for the top and bottom, but with the heat and not seeing a break in the heat till possibly mid week, I'm really leaning towards inside....The only bad thing is when it comes time to router everything flush, the mess. You know what I mean by the mess. I guess I could try attaching the suction line to the shop vac that I bought, that I've never used a shot as well???? I'm actually liking the overflow on the end as well, but leads me to the question as to should it be external or internal?

Externally you only get 1 surface skimming area vs it being internal theoretically you have 3 surface areas of skimming which in affect you could actually make it smaller if you chose to vs a large overflow being external.....Your thoughts??? I know there's others out there reading and lurking....Chime in!!!!

Quote:

Originally Posted by sweatervest13 http:///forum/thread/376802/415-gallon-plywood-tank-build/900#post_3399670

WOW. That is some BIG news. I like it!!!

I have learned to listen to the wife, she just knows better most of the time. LOL.

433G?? or is it minus one inch all around? The back and right panel where the overflow is are going to be black? That should look nice and clean. Are the holes on the bottom of the tank in the last drawing for the CL? I think you are right with the wave boxes flanking the overflow. But with the CL how would that react? I am no flow expert or anything close. LOL But would it work togheher with the CL or kind of against it? Depending on the flow pattern you were trying to achieve with the CL (per your links yesterday with the Australian guy and then the 4 45 degree elbow on the bottom front guy) I thought you were creating a wave like motion with that? But the more I think about it the more water movement the better. I was just really intrigued buy the 2 or more CL's working at different times to create a few different types of flow.

I think this is going to be an awesome build!!! Are you going to start a new thread for it?

I think that's what we calculated it out to be.....I'll actually have to get the walls constructed and take inside measurements to get inside gallonage to be exact. Actually my buddy cut them a 1" longer than my cuts, but I'm not bitchin'.....

. You always want to leave yourself a little wiggle room that way everything is square....So far from my checks of the panels no warpage. Everything seems to be well within spec, but will see as time gets closer to assembly....

. You always want to leave yourself a little wiggle room that way everything is square....So far from my checks of the panels no warpage. Everything seems to be well within spec, but will see as time gets closer to assembly....

Correct....If you are facing the aquarium the back panel and right panel which is actually inside the fish room will be black acrylic.....I splurged for black because I didn't want to be able to see inside the overflow box when looking from the front of the tank, and with the fish room behind as well was the reasoning for the right side panel. The left side viewing panel is partially exposed and half is inside the fish room, but depending how it is I might use some type of window film to darken the 1/2 that's in the fish room....Only time will tell. I have had quite a few conversations with the other master mind of this tank about buying 1/16" or 1/8" black acrylic and laminating it over the clear, but honestly wouldn't have saved me but $160-$180, but than I had to figure in the time to go pick it up and then extra purchase of glue and time spent laminating and trimming it up, and it just seemed more feasible to just purchase the black acrylic...

The wave boxes I really want, but not 100% sure???? Come on guys help me out here....That was 1 thing I originally wanted in the original design, but the more and more I keep looking at flow design; I think it's possible I could use the OM with ports drilled in the right side panel and strategically placed on the left panel as well to create the flow pattern like shown in the link????? What everyones thinking?????? I would like to generate a wave, but my initial design/concept wasn't to produce a 2"-3" wave at all....It was only to produce and gentle wave motion, and again that can all be adjusted with the timing and frequency setting on the Tunzes.....I do have the Tunzes stashed away in the closet......SSShhhhhh I have them hidden from the wife.....She doesn't know their there.....

I think I might be able to accomplish a bit more with the use of the OM, but unsure, but that would again require the use of a bigger pump to push what I want.

I think I might be able to accomplish a bit more with the use of the OM, but unsure, but that would again require the use of a bigger pump to push what I want.

The holes in the bottom of the tank are for a CL.....again nothing concrete with hole placement....That's the nice thing with acrylic....easily drilled. I'd never put returns in the bottom of the tank......As far as the wave boxes flanking the over flow, I honestly don't see it affecting the operation of the overflow box. My thinking is that if I was trying to produce a good size wave the water would have to travel from the right side of the tank to the left.....Reflect off the left wall and return roughly 6' and then with the surge returning would be forced into the overflow. The overflow will have 3 1 1/2" drains. The setup will model BeanAnimals design, so I don't think the surge or small surge would affect the overflow 1 bit.....Noise isn't really a concern as well; since it's contained in the fish room as well. I figure if the overflow was on the back wall of the tank, the return portion of the wave would actually break down or loose it's affect since the over flow opening would be on the back wall and a lot longer/larger. Basically I think it would fall off. Kind of like splashing in a pool of water, but somebody bending 1 end of the pool down letting the water escape out the lower portion; therefore on the far end you'd get minimal affect. That's what I'm not sure of, but that's my take. Hopefully someone will chime in and give use some wisdom on the matter.

Come on guys!!!!!!

Originally Posted by 2Quills http:///forum/thread/376802/415-gallon-plywood-tank-build/900#post_3399673

It's gonna be a heavy son of a gun. Are you still thinking of building it in the garage and carrying it down stairs? I think I like the changes to the overflow idea.

Externally you only get 1 surface skimming area vs it being internal theoretically you have 3 surface areas of skimming which in affect you could actually make it smaller if you chose to vs a large overflow being external.....Your thoughts??? I know there's others out there reading and lurking....Chime in!!!!

Quote:

Originally Posted by sweatervest13 http:///forum/thread/376802/415-gallon-plywood-tank-build/900#post_3399670

WOW. That is some BIG news. I like it!!!

I have learned to listen to the wife, she just knows better most of the time. LOL.

433G?? or is it minus one inch all around? The back and right panel where the overflow is are going to be black? That should look nice and clean. Are the holes on the bottom of the tank in the last drawing for the CL? I think you are right with the wave boxes flanking the overflow. But with the CL how would that react? I am no flow expert or anything close. LOL But would it work togheher with the CL or kind of against it? Depending on the flow pattern you were trying to achieve with the CL (per your links yesterday with the Australian guy and then the 4 45 degree elbow on the bottom front guy) I thought you were creating a wave like motion with that? But the more I think about it the more water movement the better. I was just really intrigued buy the 2 or more CL's working at different times to create a few different types of flow.

I think this is going to be an awesome build!!! Are you going to start a new thread for it?

I think that's what we calculated it out to be.....I'll actually have to get the walls constructed and take inside measurements to get inside gallonage to be exact. Actually my buddy cut them a 1" longer than my cuts, but I'm not bitchin'.....

Correct....If you are facing the aquarium the back panel and right panel which is actually inside the fish room will be black acrylic.....I splurged for black because I didn't want to be able to see inside the overflow box when looking from the front of the tank, and with the fish room behind as well was the reasoning for the right side panel. The left side viewing panel is partially exposed and half is inside the fish room, but depending how it is I might use some type of window film to darken the 1/2 that's in the fish room....Only time will tell. I have had quite a few conversations with the other master mind of this tank about buying 1/16" or 1/8" black acrylic and laminating it over the clear, but honestly wouldn't have saved me but $160-$180, but than I had to figure in the time to go pick it up and then extra purchase of glue and time spent laminating and trimming it up, and it just seemed more feasible to just purchase the black acrylic...

The wave boxes I really want, but not 100% sure???? Come on guys help me out here....That was 1 thing I originally wanted in the original design, but the more and more I keep looking at flow design; I think it's possible I could use the OM with ports drilled in the right side panel and strategically placed on the left panel as well to create the flow pattern like shown in the link????? What everyones thinking?????? I would like to generate a wave, but my initial design/concept wasn't to produce a 2"-3" wave at all....It was only to produce and gentle wave motion, and again that can all be adjusted with the timing and frequency setting on the Tunzes.....I do have the Tunzes stashed away in the closet......SSShhhhhh I have them hidden from the wife.....She doesn't know their there.....

The holes in the bottom of the tank are for a CL.....again nothing concrete with hole placement....That's the nice thing with acrylic....easily drilled. I'd never put returns in the bottom of the tank......As far as the wave boxes flanking the over flow, I honestly don't see it affecting the operation of the overflow box. My thinking is that if I was trying to produce a good size wave the water would have to travel from the right side of the tank to the left.....Reflect off the left wall and return roughly 6' and then with the surge returning would be forced into the overflow. The overflow will have 3 1 1/2" drains. The setup will model BeanAnimals design, so I don't think the surge or small surge would affect the overflow 1 bit.....Noise isn't really a concern as well; since it's contained in the fish room as well. I figure if the overflow was on the back wall of the tank, the return portion of the wave would actually break down or loose it's affect since the over flow opening would be on the back wall and a lot longer/larger. Basically I think it would fall off. Kind of like splashing in a pool of water, but somebody bending 1 end of the pool down letting the water escape out the lower portion; therefore on the far end you'd get minimal affect. That's what I'm not sure of, but that's my take. Hopefully someone will chime in and give use some wisdom on the matter.

Come on guys!!!!!!

al&burke

Active Member

Hey Shawn - whoh that is some thick acrylic - are the guys at the shop jointing the edges as well. The only thing i see with the overflow is the thickness of the plexi I would be worried about cutting that many slots in 1" thick material as supposed to drilling a larger hole with a holesaw. But I think from what I have seen you do you have that figured out. Make sure you post a lot of pictures my friend.

acrylic51

Active Member

Hey Al!!!!! It's been awhile.....Very true...1" thick acrylic is actually insane....You really don't have a concept of the material until you actually have it in front of you. For sure the thickest I've ever worked, so will require a little learning and practice with on my part. Actually I've been practicing on some scrap and even without prepping the edges on the scrap and rushing I've getting a pretty clean joint.....Actually I think some has to do with the edges not being prepped, and playing with the time I'm letting the solvent sit before pulling the pins. I'm in the process of building some new jigs to model James of Envision, and thinking the way he uses his jigs, might be the ticket

Al honestly not to worried about cutting the slots into the 1" material. The overflow will be on the end....99.9% sure in my mind....Still waiting to see if someone has a reason or rationale as to keeping it on the back wall???? My plan is cutting the start and end of the overflow slot with a holesaw bit, and of course there will be a jig made as well for keeping everything straight and tight, but the bit I'm going to use for actually cutting the slot will be a Triple fluted spiral upcut bit. Honestly it won't be a bunch of slits. I'm leaning away from the "teeth" style only because it cuts down flow, and increases noise a bit. The spiral upcut bit will give a cleaner cut, and it's triple fluted......

My buddies at the shop did prep the edges. The didn't use the jointer as they traditional due only due to the fact of size of the panels.....The top and bottom panels I didn't have them prep the edges do to the fact it's cut oversize, and will be routed flush anyways, so why waste their time cleaning up the edges, when I'm going to cut them away anyways.........They had to use the router table, and they have several routers setup into big work tables to clean up the edges. Actually didn't look bad with the saw cut edges as well. Again they aren't using the typical table saws we use at home; you know first hand the equipment used. I being anal retentive am actually going over every edge with 1200 grit wet/dry sandpaper as we speak. I think edge prep is key to a good solid glue joint......

Al honestly not to worried about cutting the slots into the 1" material. The overflow will be on the end....99.9% sure in my mind....Still waiting to see if someone has a reason or rationale as to keeping it on the back wall???? My plan is cutting the start and end of the overflow slot with a holesaw bit, and of course there will be a jig made as well for keeping everything straight and tight, but the bit I'm going to use for actually cutting the slot will be a Triple fluted spiral upcut bit. Honestly it won't be a bunch of slits. I'm leaning away from the "teeth" style only because it cuts down flow, and increases noise a bit. The spiral upcut bit will give a cleaner cut, and it's triple fluted......

My buddies at the shop did prep the edges. The didn't use the jointer as they traditional due only due to the fact of size of the panels.....The top and bottom panels I didn't have them prep the edges do to the fact it's cut oversize, and will be routed flush anyways, so why waste their time cleaning up the edges, when I'm going to cut them away anyways.........They had to use the router table, and they have several routers setup into big work tables to clean up the edges. Actually didn't look bad with the saw cut edges as well. Again they aren't using the typical table saws we use at home; you know first hand the equipment used. I being anal retentive am actually going over every edge with 1200 grit wet/dry sandpaper as we speak. I think edge prep is key to a good solid glue joint......