acrylic51

Active Member

Some Updates!!!!!!!

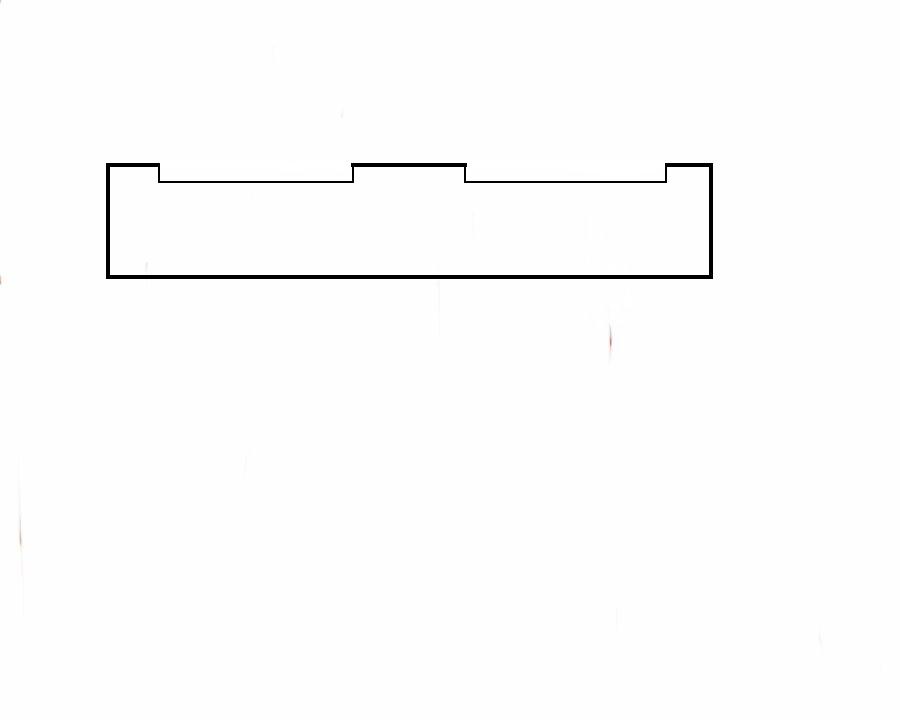

After figuring out what was going on with the edges not wanting to take glue, and the use of the hand held planer this is the end result making a pass over the edges......Corey it's pretty easy to prep your edges this way. The only thing I'd recommend is guides on both sides of the work piece to make sure you don't teeter either way...... You'll also see that I also cut the holes for the bulkheads in the overflow....I will be utilizing BeanAnimals design, and the holes are cut for sched 80 1.5 bulkheads.....

Her's is the piece mocked up, and pins pulled......I had mentioned to Corey that I switched from twisty ties to straight pins, out of my daughters sewing kit.....Works great, just the little ball heads on the pins like to come off occasionally, so I keep the piers handy and you can see 1 of the pins sticking in the pliers......

After figuring out what was going on with the edges not wanting to take glue, and the use of the hand held planer this is the end result making a pass over the edges......Corey it's pretty easy to prep your edges this way. The only thing I'd recommend is guides on both sides of the work piece to make sure you don't teeter either way...... You'll also see that I also cut the holes for the bulkheads in the overflow....I will be utilizing BeanAnimals design, and the holes are cut for sched 80 1.5 bulkheads.....

Her's is the piece mocked up, and pins pulled......I had mentioned to Corey that I switched from twisty ties to straight pins, out of my daughters sewing kit.....Works great, just the little ball heads on the pins like to come off occasionally, so I keep the piers handy and you can see 1 of the pins sticking in the pliers......