acrylic51

Active Member

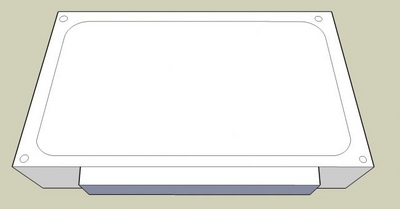

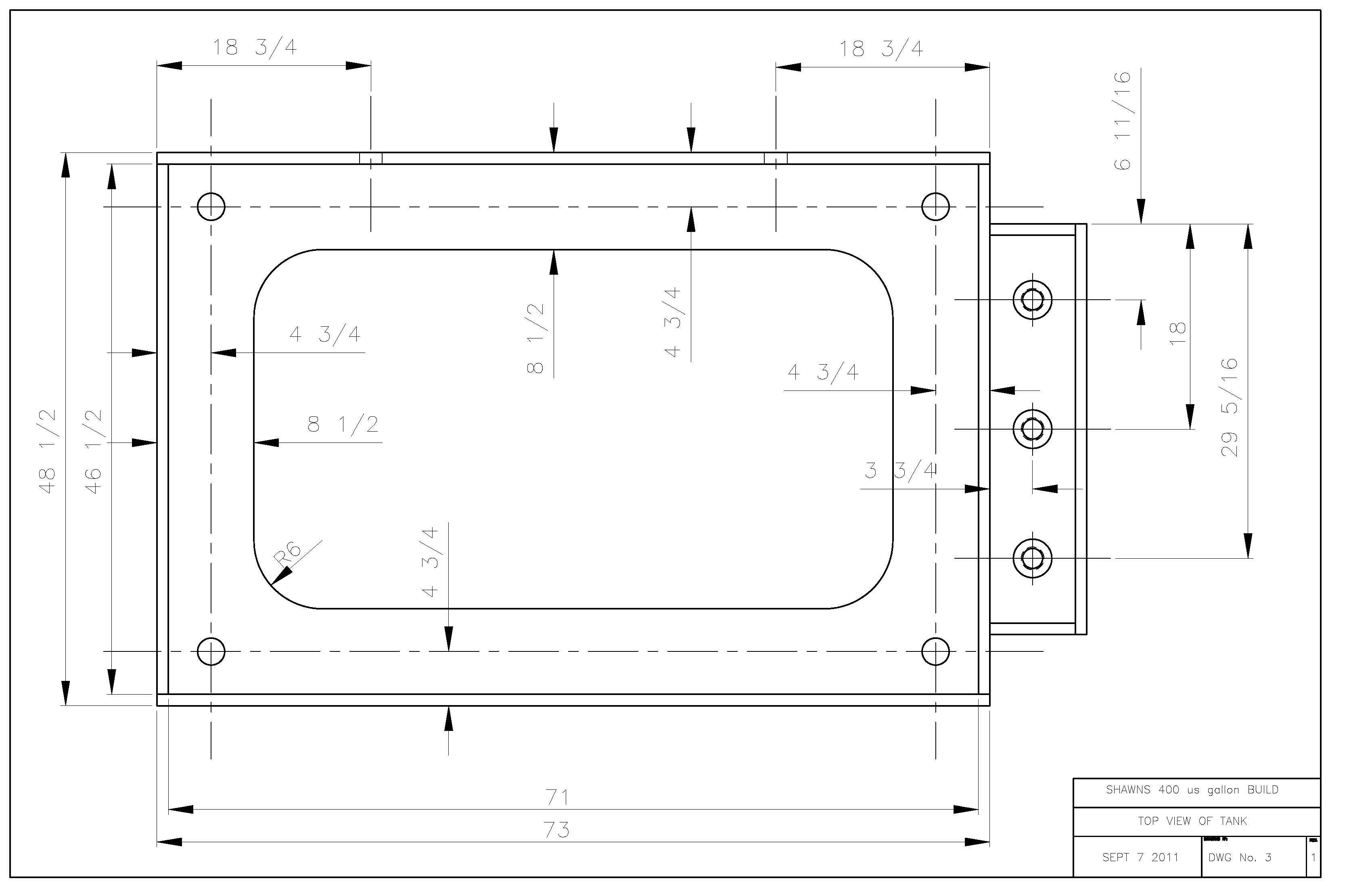

Ok guys!!!!!! Had a little time to think it over, and I fully understand the plan I threw up there would be hard to replicate, but as it was pointed out I think most of the time we honestly overlook things such as water flow within the system.....Again as we all know and understand an empty will create a flow pattern differently than a tank with rock work. We also know that as corals grow in that again the water flow patter will change, and decrease. My main major goal was to keep the tank as clean as possible without clutter from PH's.

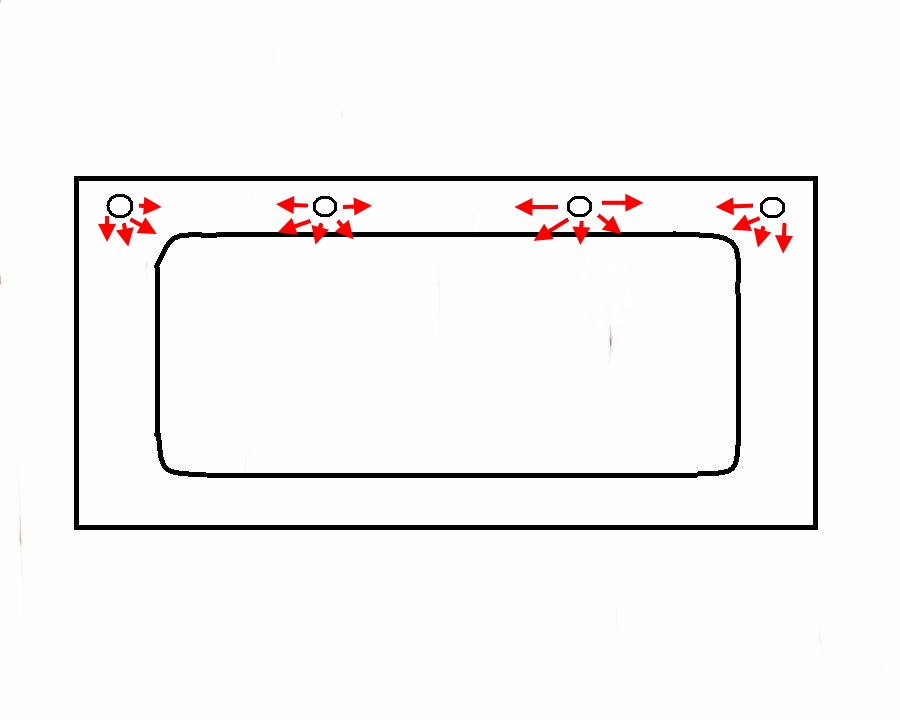

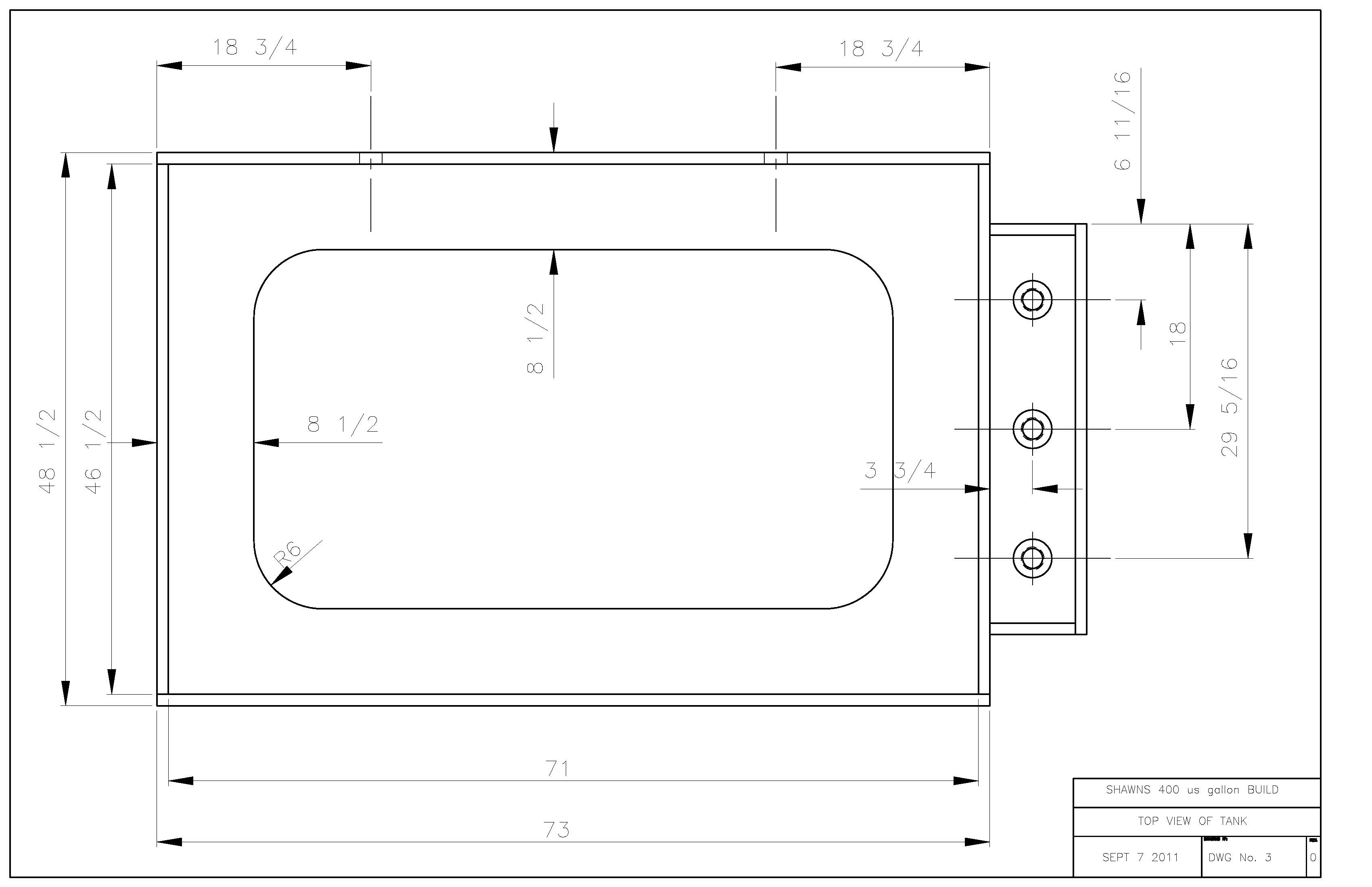

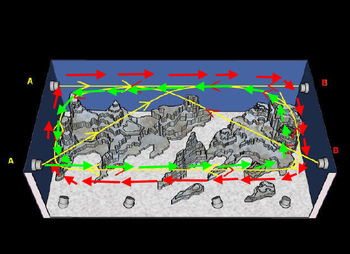

I like the idea of the flow pattern here, and this I think wouldn't be affected much by rock work and could easily be adjusted to work around the rock work. The rock work shown in the pic is similar to the 2 islands I'd like to create, but not exact.....I do want to leave the middle open somewhat for a good swim area. The real issue with this style plumbing is the bulkhead on the left front of the side viewing panel....There is NO Way I can drill that far forward on the tank...... Again I fully understand your analogy Corey when you reference a tennis ball hitting a wall vs. water hitting a glass panel.....You might not get the full inertia of water, but a portion of that flow being bounced and directed is all were looking for to a certain degree.....You figure a wave is created in 1 shot, but it's the continual movement back and forth that creates that wave to increase energy, strength, and thereby becoming larger.....

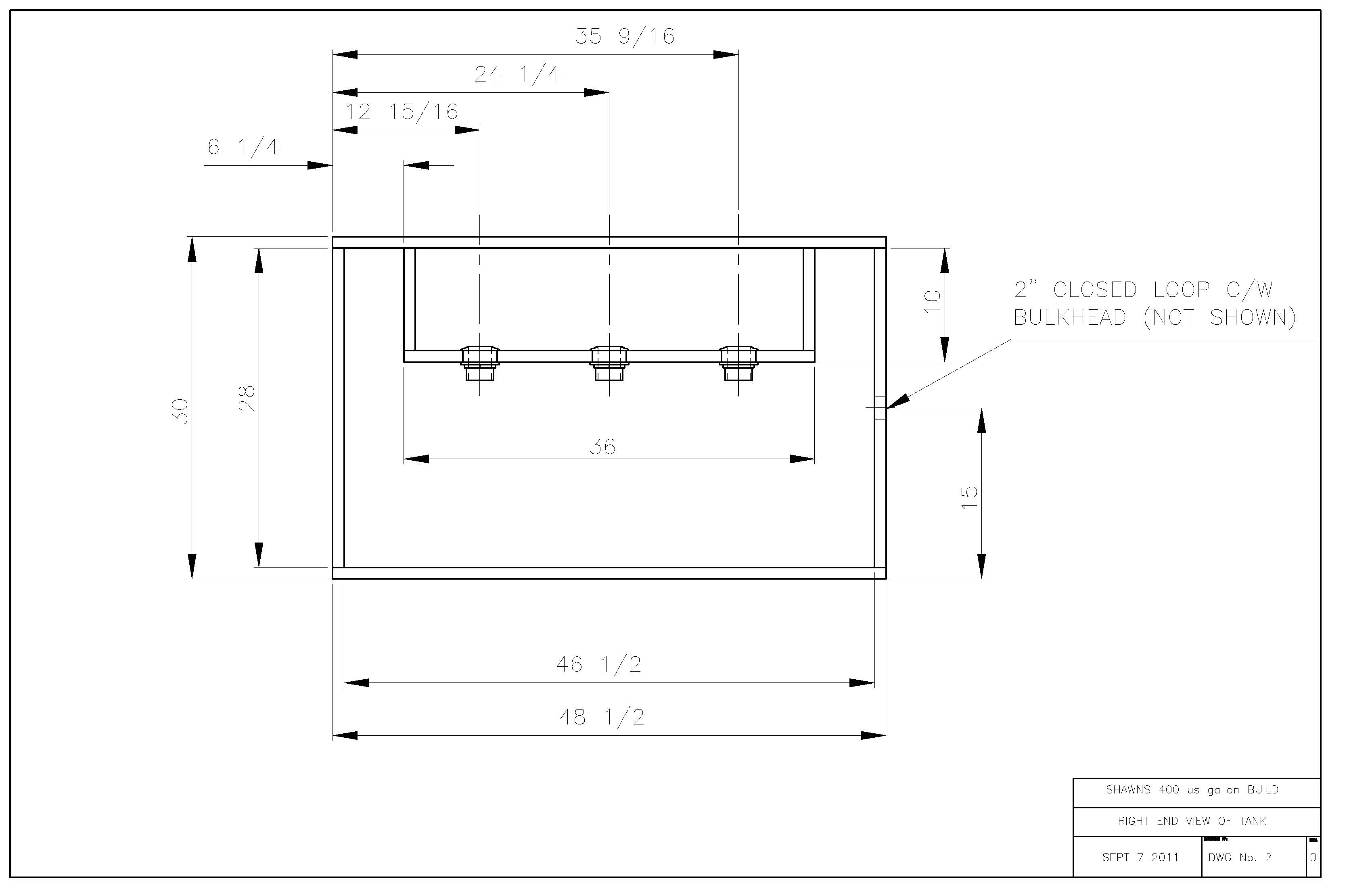

This is the area where I think if the bulkheads were drilling in the eurobracing, and again keep in mind that I'm not using standard PVC to direct flow.....I'm considering using the Omni Nozzles which give me a bit more control and angling ability.....Something similar to loc line. I do agree that with the bulkheads mounted in the bottom near the front panel wouldn't give me what I'm after, but think possibly I would get more of the "roll" affect from mounting in the eurobracing, because I could fire them at a sharp angle downward. A problem could arise as mentioned early creating a sand storm.

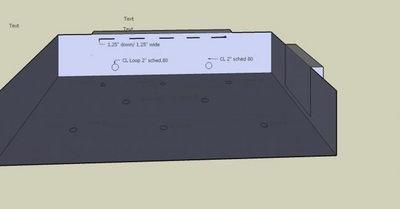

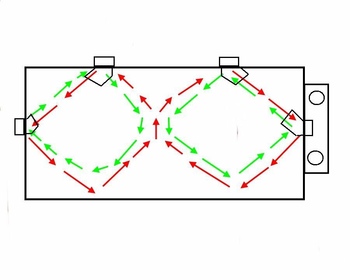

This image right here I'm liking, but again I still think the flow is lacking.......Lacking IMO because I'm still not pulling water from top to bottom, which even looking over the OM forum is something Paul likes to see and thinks as well that it benefits a system.....I think this could be accomplished a couple different ways.....I could be done with a OM 4Way or 2 OM Squirts.....The Squirts don't handle as much pump pressure though.....

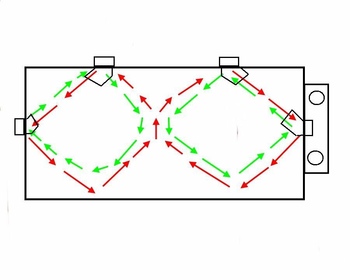

The only thing I wonder is how effective it will be????? You would almost have to run 2 OM 4Ways, and have them and the pumps plugged in a controller, and have the controller run 1 setup in 1 direction for "X" amount of time, and then shut that system down and fire the other system and run the opposite direction. Any thoughts on that?

This is something Paul usually recommends......

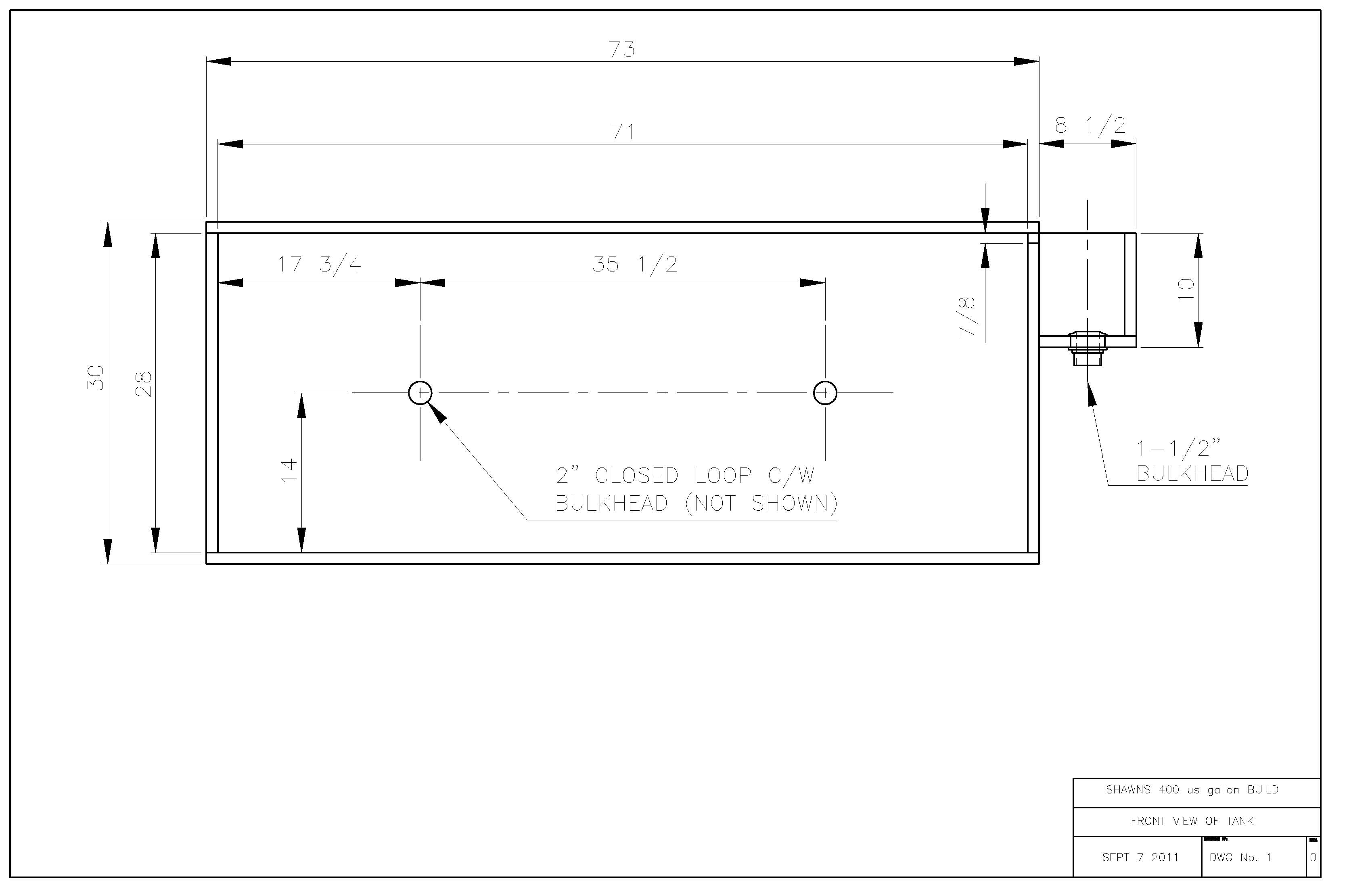

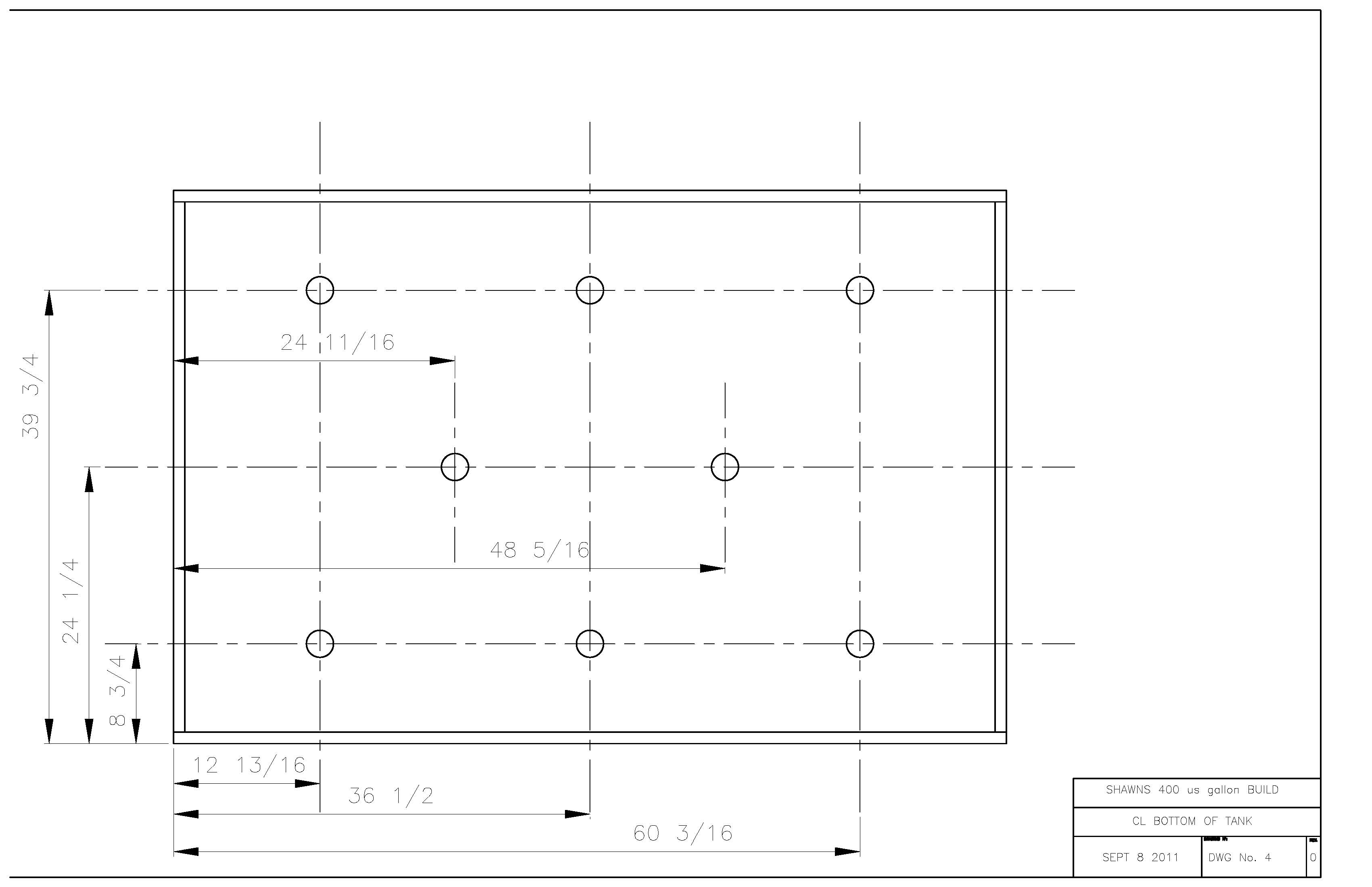

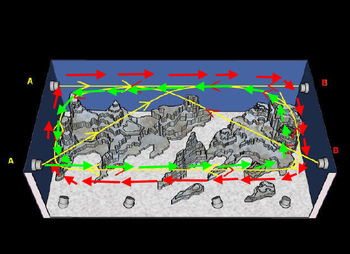

The top 2 nozzles on the back wall are the returns from the sump......The manifold on the bottom back wall is the drain for the CL, and as you can see he has done 2 mounted in the bottom near the front panel aimed up and back and 2 along the back wall aimed forward to achieve the roll...??????

I like the idea of the flow pattern here, and this I think wouldn't be affected much by rock work and could easily be adjusted to work around the rock work. The rock work shown in the pic is similar to the 2 islands I'd like to create, but not exact.....I do want to leave the middle open somewhat for a good swim area. The real issue with this style plumbing is the bulkhead on the left front of the side viewing panel....There is NO Way I can drill that far forward on the tank...... Again I fully understand your analogy Corey when you reference a tennis ball hitting a wall vs. water hitting a glass panel.....You might not get the full inertia of water, but a portion of that flow being bounced and directed is all were looking for to a certain degree.....You figure a wave is created in 1 shot, but it's the continual movement back and forth that creates that wave to increase energy, strength, and thereby becoming larger.....

This is the area where I think if the bulkheads were drilling in the eurobracing, and again keep in mind that I'm not using standard PVC to direct flow.....I'm considering using the Omni Nozzles which give me a bit more control and angling ability.....Something similar to loc line. I do agree that with the bulkheads mounted in the bottom near the front panel wouldn't give me what I'm after, but think possibly I would get more of the "roll" affect from mounting in the eurobracing, because I could fire them at a sharp angle downward. A problem could arise as mentioned early creating a sand storm.

This image right here I'm liking, but again I still think the flow is lacking.......Lacking IMO because I'm still not pulling water from top to bottom, which even looking over the OM forum is something Paul likes to see and thinks as well that it benefits a system.....I think this could be accomplished a couple different ways.....I could be done with a OM 4Way or 2 OM Squirts.....The Squirts don't handle as much pump pressure though.....

The only thing I wonder is how effective it will be????? You would almost have to run 2 OM 4Ways, and have them and the pumps plugged in a controller, and have the controller run 1 setup in 1 direction for "X" amount of time, and then shut that system down and fire the other system and run the opposite direction. Any thoughts on that?

This is something Paul usually recommends......

The top 2 nozzles on the back wall are the returns from the sump......The manifold on the bottom back wall is the drain for the CL, and as you can see he has done 2 mounted in the bottom near the front panel aimed up and back and 2 along the back wall aimed forward to achieve the roll...??????