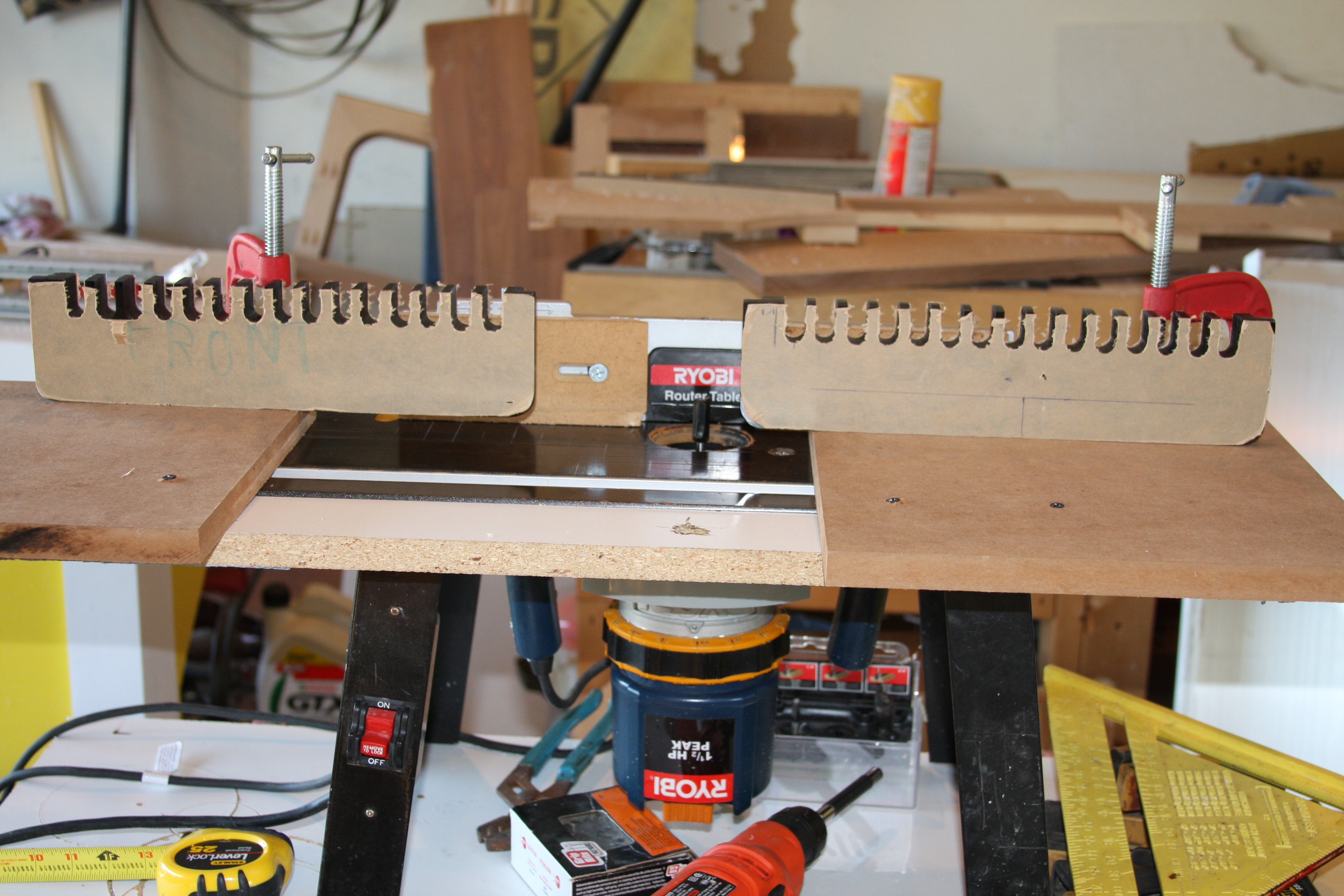

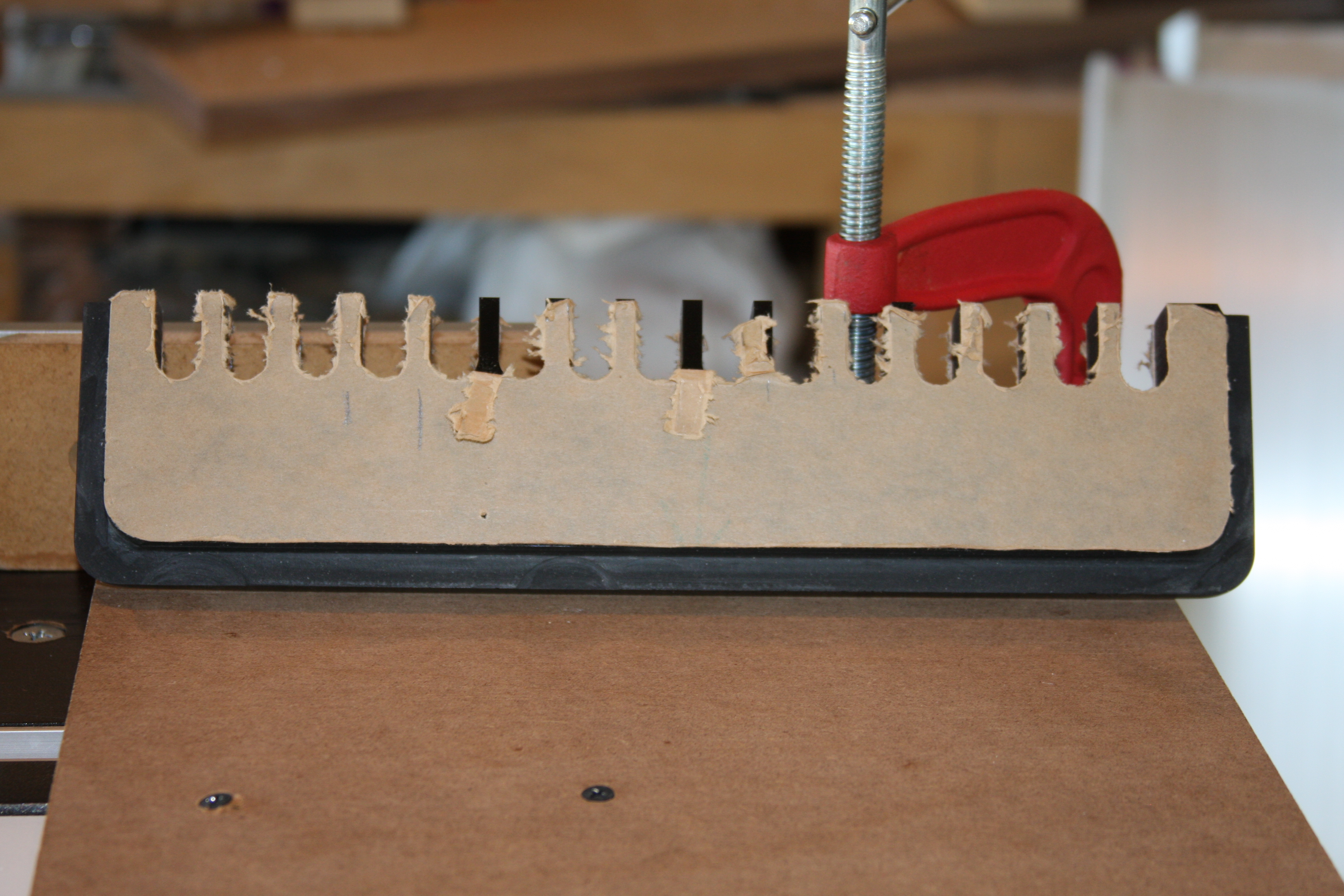

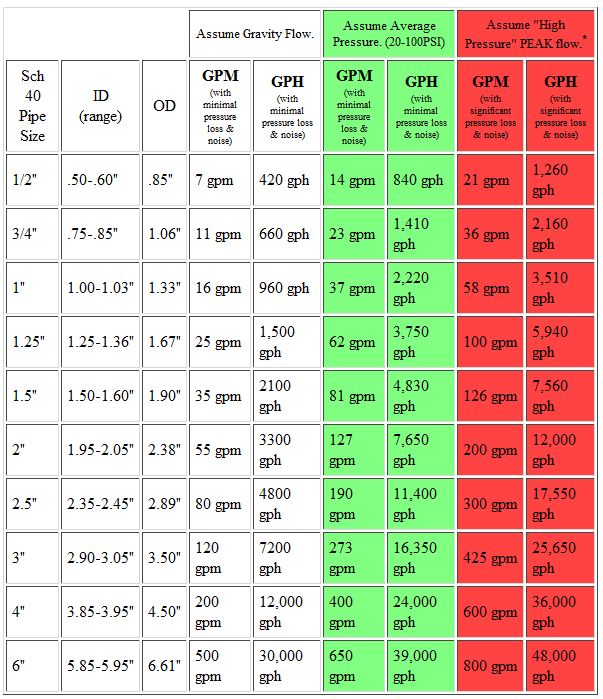

Again to be able to cut the teeth straight and consistently at the same depth, I used my old trusty, beat up router table.......You can see in the pic the crude jig I fabricated as well to keep the piece from wanting to slide side to side while cutting material......If any of you have ever tried to do it free hand you know exactly the purpose of having supports on both sides of the work piece....You don't want your guides so tight that the piece binds up, but snug enough that it doesn't wiggle side to side......Again cheap MDF used for the jig and clamp......I marked the layout on each panel, and the jig, can be slid to line the cut mark with the bit.....I think Corey has something similar made for his handheld router?????

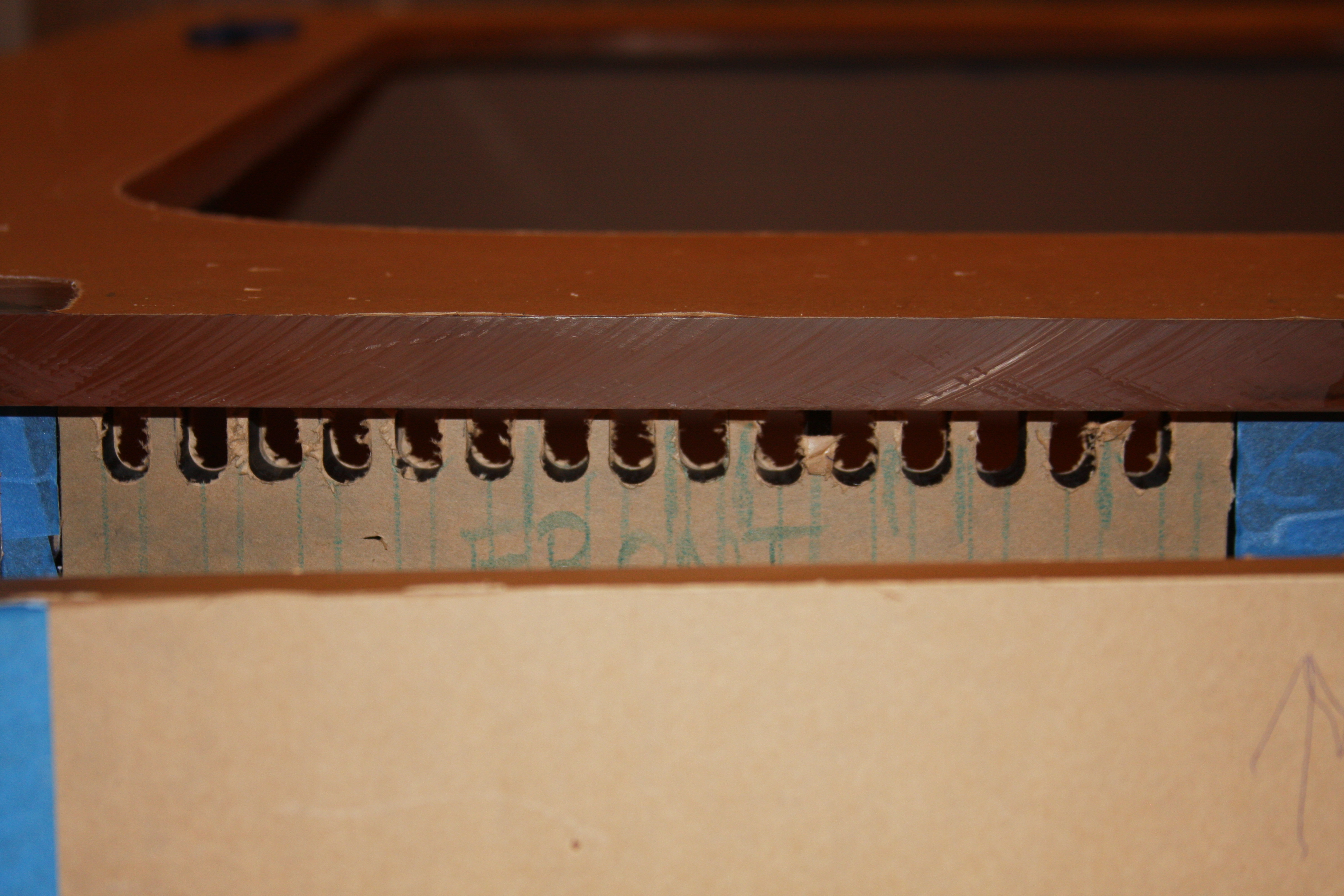

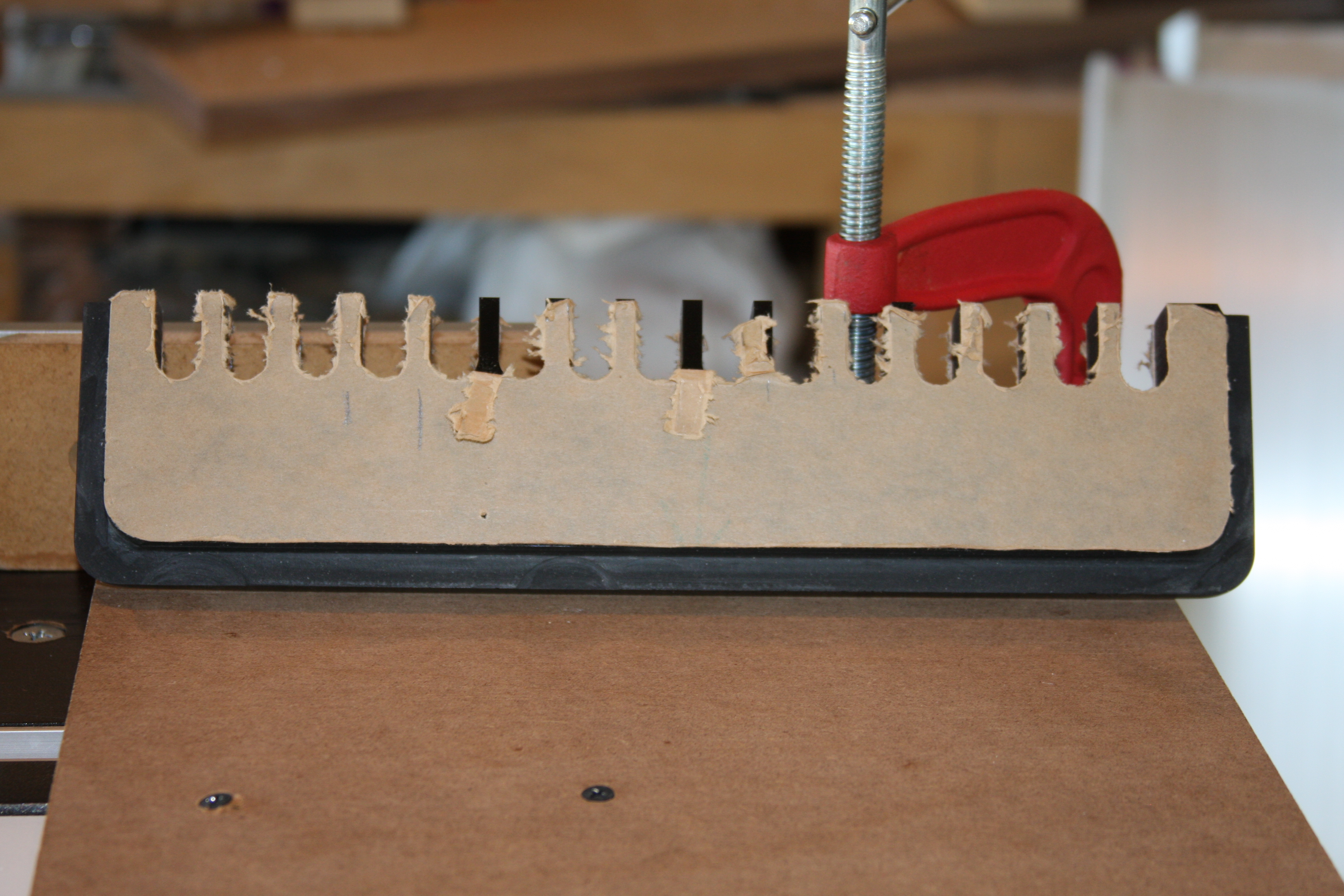

Here's the completed covers......Took quite a bit of time......Worked till 2:00 am this morning and then lost power due to the storms, and finally got power back and finished the router work cutting the teeth......Originally I had talked about using 3/8" material for the covers, but in the back of my mind flexing was a major concern and figured with a little extra work on my part, I could used some of the extra 1" black acrylic I had sitting around......Using the 1" acrylic meant that there would be extra steps, cuts neeed to make them fit flush as I want/expect......

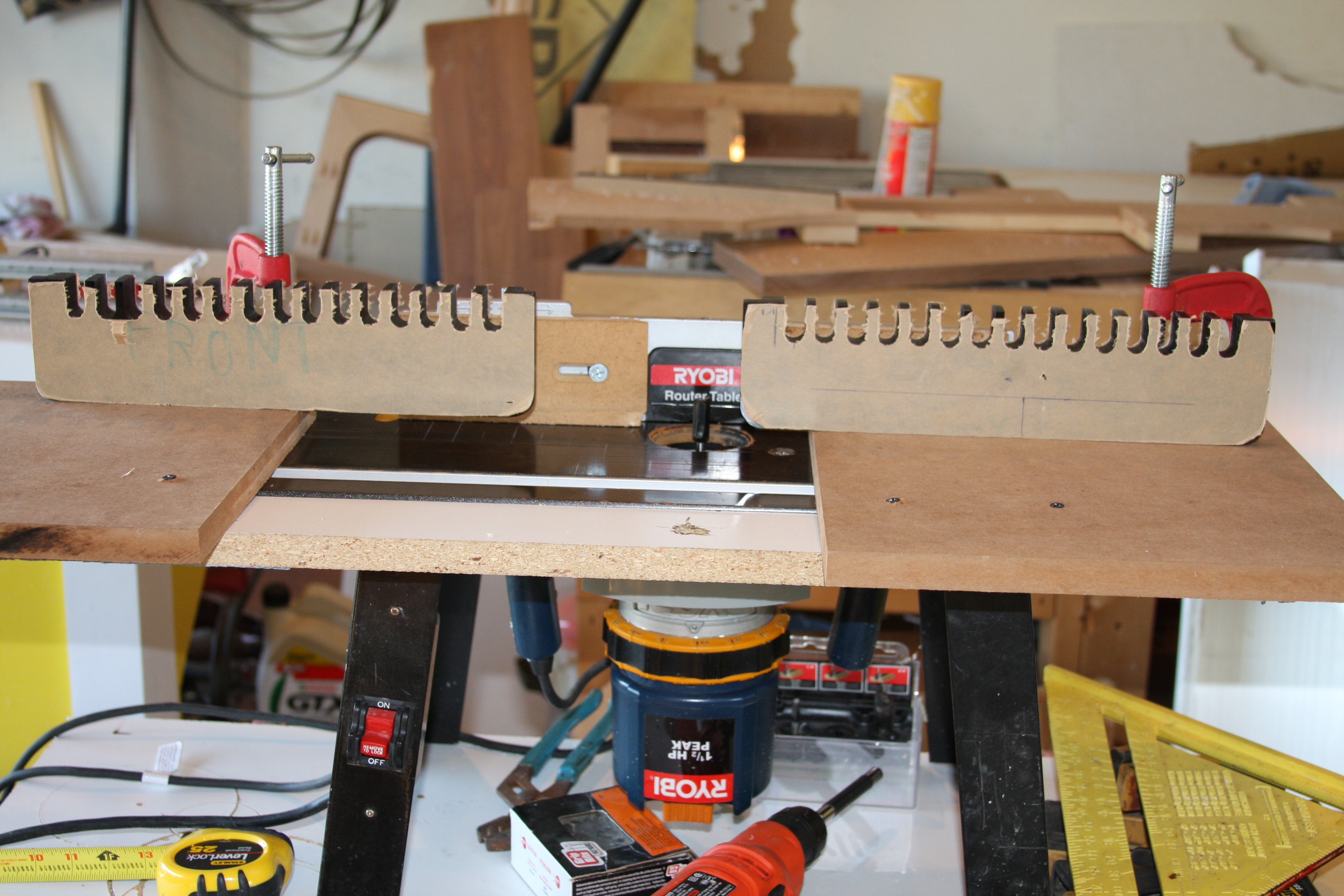

We had also talked and debated on overflow teeth size and spacing......I was already cutting when Corey texted me back!!!!!! Thanks Buddy!!!!! I know it was late, but wanted to get them started. I originally layed everything out using a 1/2" teeth with 1/4" spacing between the teeth.....With this spacing I was able to get 15 teeth per panel......What I ultimately did during the cutting process was narrow the spacing down between the teeth, which allowed me to bump my teeth width to roughly 9/16" wide.......

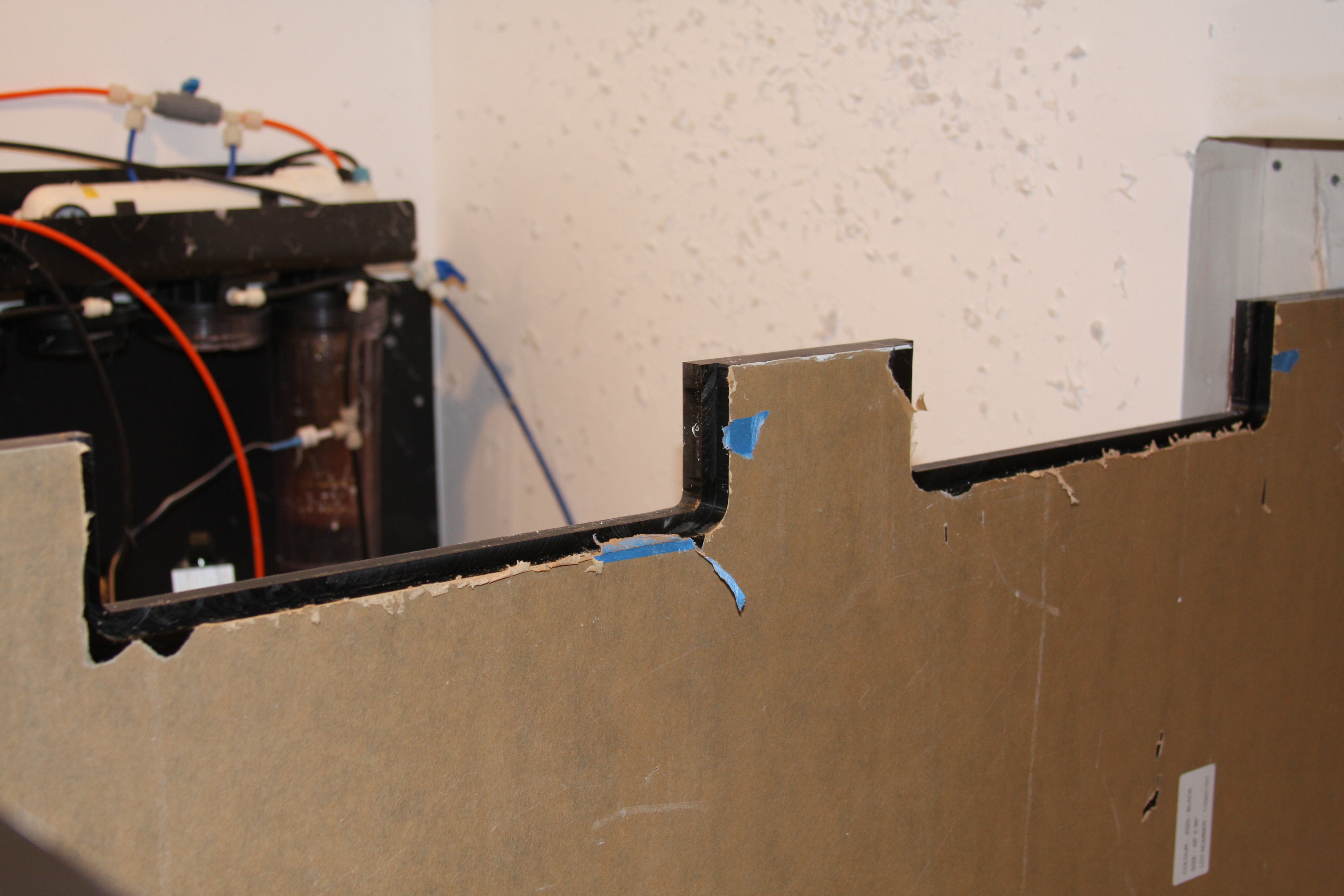

In this pic you can see that even the backside of the overflow covers/grills had to be recessed just as the panel of the tank....The reasoning behind this; is that I wanted the covers to be perfectly flush with the panel of the tank.......

This is a side shot of the overflow cover/grills.....In the pic you can see that the corners had to be rounded since the cuts in the tank panel are rounded, so everything has to be rounded somewhat to get a good fit.....Again the rabbeting router bit was used......

This is the mess after doing all the routing just on the 2 small overflow covers......Imagine the mess from routing the tank flush!!!!!!