acrylic51

Active Member

Thanks Al.......I didn't even see that you had updated the drawings.......I spent quite a bit of time on the phone yesterday morning with Paul from OM.....I have to tell you, it's not many times you'd find a company owner who would get up at the crack of dawn and make a phone call/email to get you out of bed. Paul knows my schedule is hectic and we played phone tag all week, so Saturday morning worked for both of us.......

He gave me tons of ideas and stuff to think about......I'd honestly tell anyone, who's seriously thinking about water movement and how to make a tank move with efficiency to give him a call, and pick his brain. The nice thing about him is that he doesn't try to sway you to purchase his products. He already knew that I had the Tunzes and suggested if I could live with the cord issues it would save money......We all know I can't deal with the cords......And Vortech's don't have the adjustability needed for the job......

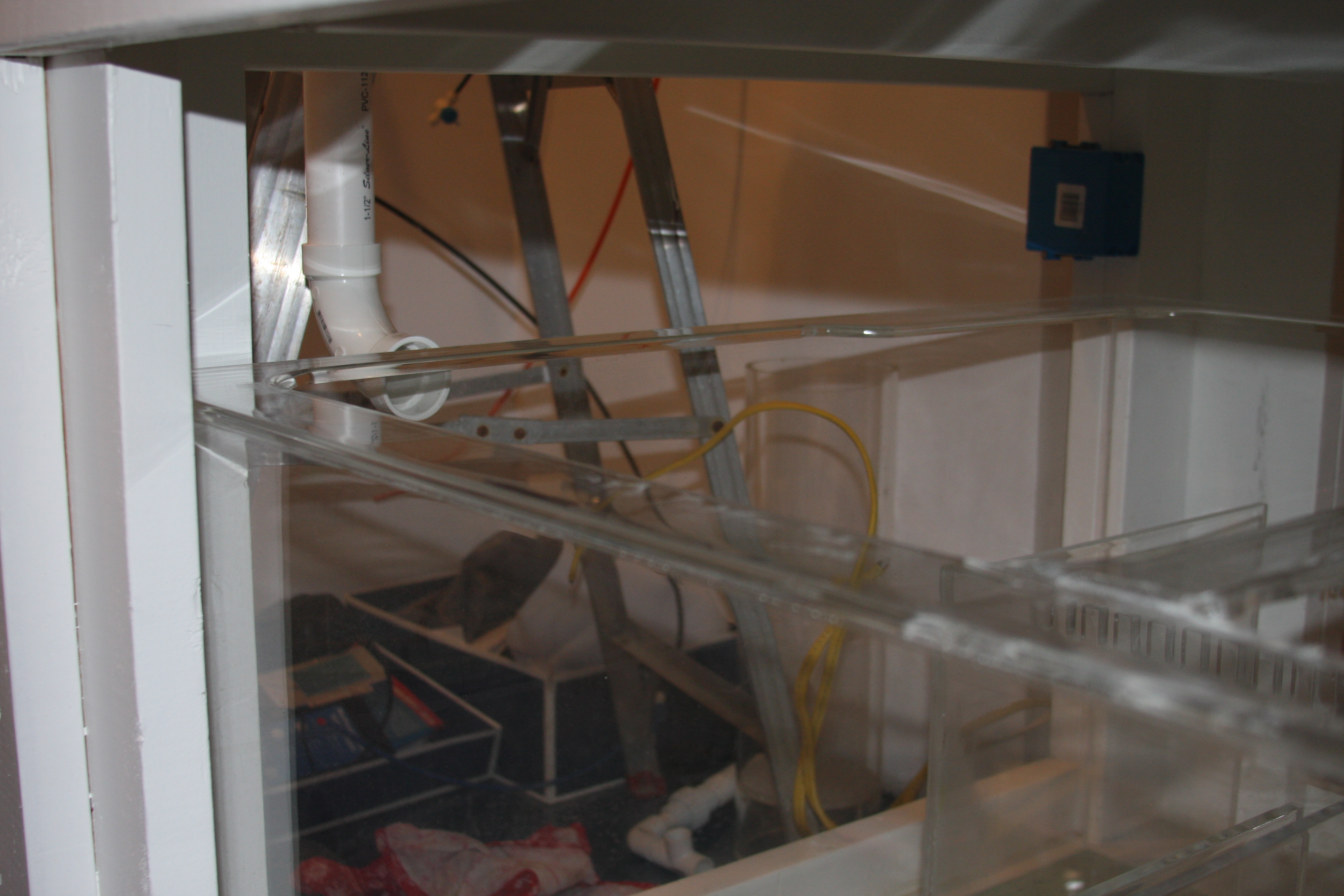

Anyways the drawings are perfect.......The only thing Paul and I did change or considered was either going with 6 bulkheads in the bottom or 8.....Not totally sure at this stage, but leaning towards the 8 bulkheads in the bottom, and ultimately there would be a total of 3 separate CL systems on the tank......I'm in the process of trying to gather info/thoughts on whether shutting down a CL for a period of time would actually cause any detriment to the system. The reasoning for wanting to shut a CL down for a period of time would be 1 to change the flow pattern up in the DT, but also to create a possible night time current flow during the lights out period......Again something that occurs in nature.

The bottom of the tank would actually consist of 8 bulkheads; which would be on 2 separate CL systems. The back wall would be on it's own CL as well......Early planning I would be opting to run the back wall CL alone during night time.....This by itself would slow the barrel roll down which will be running the length of the tank, but then the tank would have 2 distinct circular patterns during the night.....The flow would be rather slow/low across the bottom, but once the lights kick in, the flow would increase tremendously.

Everyones thinking????????

He gave me tons of ideas and stuff to think about......I'd honestly tell anyone, who's seriously thinking about water movement and how to make a tank move with efficiency to give him a call, and pick his brain. The nice thing about him is that he doesn't try to sway you to purchase his products. He already knew that I had the Tunzes and suggested if I could live with the cord issues it would save money......We all know I can't deal with the cords......And Vortech's don't have the adjustability needed for the job......

Anyways the drawings are perfect.......The only thing Paul and I did change or considered was either going with 6 bulkheads in the bottom or 8.....Not totally sure at this stage, but leaning towards the 8 bulkheads in the bottom, and ultimately there would be a total of 3 separate CL systems on the tank......I'm in the process of trying to gather info/thoughts on whether shutting down a CL for a period of time would actually cause any detriment to the system. The reasoning for wanting to shut a CL down for a period of time would be 1 to change the flow pattern up in the DT, but also to create a possible night time current flow during the lights out period......Again something that occurs in nature.

The bottom of the tank would actually consist of 8 bulkheads; which would be on 2 separate CL systems. The back wall would be on it's own CL as well......Early planning I would be opting to run the back wall CL alone during night time.....This by itself would slow the barrel roll down which will be running the length of the tank, but then the tank would have 2 distinct circular patterns during the night.....The flow would be rather slow/low across the bottom, but once the lights kick in, the flow would increase tremendously.

Everyones thinking????????