415 Gallon Plywood Tank Build

- Thread starter acrylic51

- Start date

acrylic51

Active Member

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1100#post_3414504

Hey Shawn I have a question about the 8Way OM with the 8 outlets - that gets hooked up to the discharge of your CL pump where do you hook the inlet to your sump or in the main tank - does there have to be a hole in the DT for it as well.

Hopefully I can explain it pretty simple and not confuse you as I can at times......

The CL pump gets it's water feed/supply from the (2) 2" bulkheads drilled in the back panel of the tank......The line that comes off those bulkheads will be separate from the bulkheads, but will be joined into 1 line going into the suction side of the pump. The OM can be mounted several different ways; places, but I plan to mount the OM pretty close to the pump. What you would then do is run pipe up from the output of the pump, to the bottom side of the OM. At that point the water is distributed through the outlets of the OM depending on which ports are open on the drum inside the OM. The open ports on the drum will direct water to whichever line it's connect to.

The return pump coming off the sump will feed the 2 1 1/2" bulkheads mounted in the euro bracing on the side where the overflow is mounted.....That is where the return pump will pump back into the tank. I'm choosing to mount the returns in this area for a couple reasons. 1) to minimize clutter inside the tank and on the side wall. 2) I think I can get a better push on the water downward from this area, and it really reduces the amount of back siphon in the event power would go out, because very little of the nozzle will be submerged in the water itself. I'm also planning on having 2 additional returns mounted in the euro bracing as well, but on the far end of the tank facing/pointing back towards the overflow......

Hopefully I explained what you were asking and didn't confuse anyone?????

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1100#post_3414504

Hey Shawn I have a question about the 8Way OM with the 8 outlets - that gets hooked up to the discharge of your CL pump where do you hook the inlet to your sump or in the main tank - does there have to be a hole in the DT for it as well.

Hopefully I can explain it pretty simple and not confuse you as I can at times......

The CL pump gets it's water feed/supply from the (2) 2" bulkheads drilled in the back panel of the tank......The line that comes off those bulkheads will be separate from the bulkheads, but will be joined into 1 line going into the suction side of the pump. The OM can be mounted several different ways; places, but I plan to mount the OM pretty close to the pump. What you would then do is run pipe up from the output of the pump, to the bottom side of the OM. At that point the water is distributed through the outlets of the OM depending on which ports are open on the drum inside the OM. The open ports on the drum will direct water to whichever line it's connect to.

The return pump coming off the sump will feed the 2 1 1/2" bulkheads mounted in the euro bracing on the side where the overflow is mounted.....That is where the return pump will pump back into the tank. I'm choosing to mount the returns in this area for a couple reasons. 1) to minimize clutter inside the tank and on the side wall. 2) I think I can get a better push on the water downward from this area, and it really reduces the amount of back siphon in the event power would go out, because very little of the nozzle will be submerged in the water itself. I'm also planning on having 2 additional returns mounted in the euro bracing as well, but on the far end of the tank facing/pointing back towards the overflow......

Hopefully I explained what you were asking and didn't confuse anyone?????

acrylic51

Active Member

An idea on some of the plumbing possible with the OM.

http://www.oceansmotions.com/8wayC4.htm

http://www.oceansmotions.com/8wayC4.htm

acrylic51

Active Member

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1100#post_3414502

Shawn don't worry about the changes - here is what I think you wanted. Let me know if you need it changed

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1100#post_3414502

Shawn don't worry about the changes - here is what I think you wanted. Let me know if you need it changed

al&burke

Active Member

Quote:

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414524

An idea on some of the plumbing possible with the OM.

http://www.oceansmotions.com/8wayC4.htm

OK is see there is a large 2" inlet to the pump from the DT. Cool thinking of the future.

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414524

An idea on some of the plumbing possible with the OM.

http://www.oceansmotions.com/8wayC4.htm

OK is see there is a large 2" inlet to the pump from the DT. Cool thinking of the future.

acrylic51

Active Member

Not a problem Al.....The Dart pumps utilize a 2" intake, but the Baracuda and HammerHead have an 1 1/2" intake and discharge. I just prefer to oversize my plumbing and flood the pump. Also in the event that 1 bulkhead would clog for whatever reason the pump wouldn't be starved of water.

al&burke

Active Member

Quote:

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414552

Not a problem Al.....The Dart pumps utilize a 2" intake, but the Baracuda and HammerHead have an 1 1/2" intake and discharge. I just prefer to oversize my plumbing and flood the pump. Also in the event that 1 bulkhead would clog for whatever reason the pump wouldn't be starved of water.

So vat vould be da price tag on vne ov des devices be - may I ask

Originally Posted by acrylic51 http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414552

Not a problem Al.....The Dart pumps utilize a 2" intake, but the Baracuda and HammerHead have an 1 1/2" intake and discharge. I just prefer to oversize my plumbing and flood the pump. Also in the event that 1 bulkhead would clog for whatever reason the pump wouldn't be starved of water.

So vat vould be da price tag on vne ov des devices be - may I ask

acrylic51

Active Member

$459.00 plus shipping....Another alternative would be a VFD pump....It's a DIY project utilizing a 3phase motor and the wet end off of a Reeflo Baracuda and some additional pieces, and some fine tuning, but seems very promising.....I've spent quite a bit of time reading again on them. Maybe down the road I might swap to something like that though.

acrylic51

Active Member

Hey what's up Corey!!!!! Strange no texts today!!!!!!

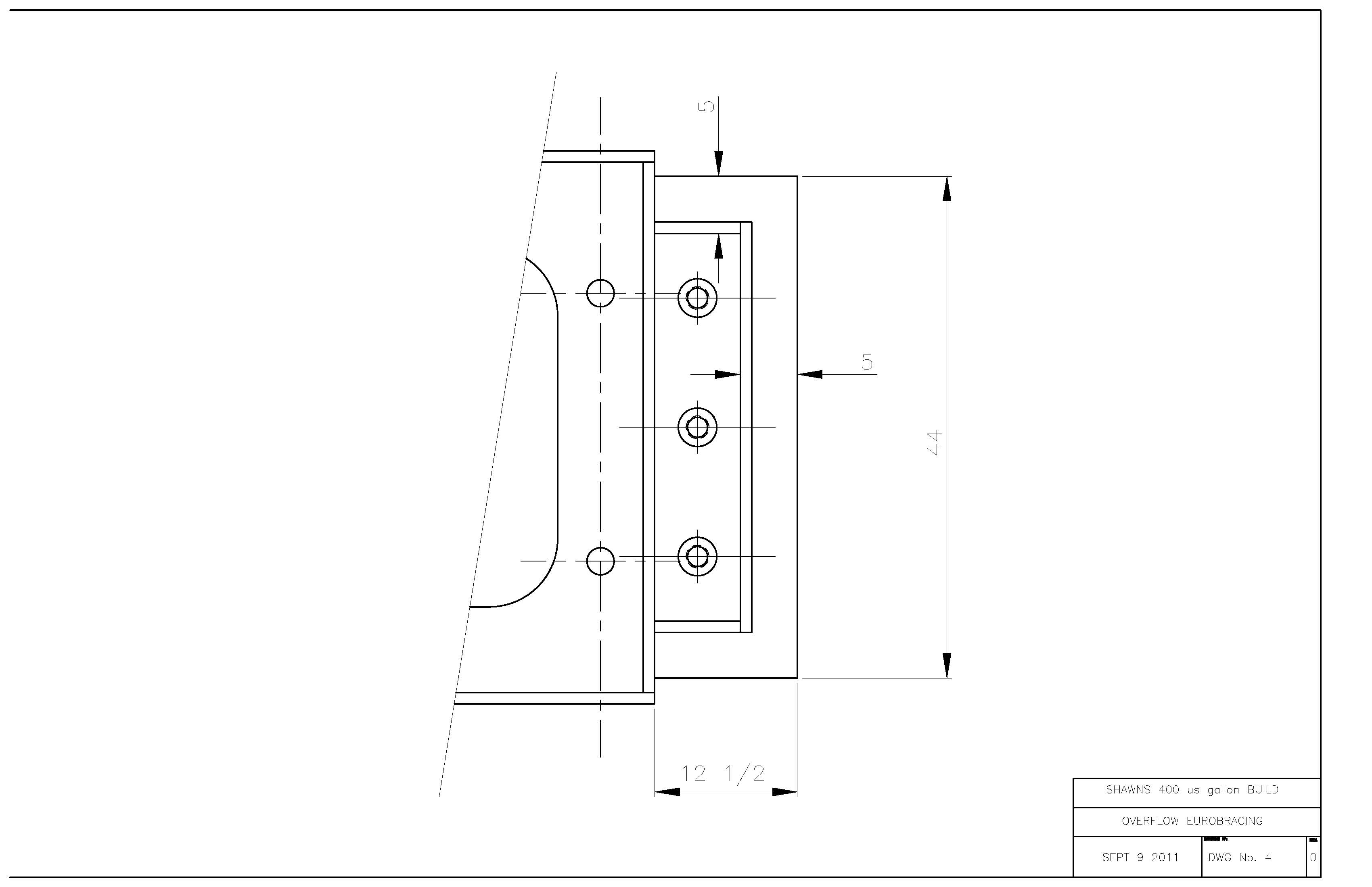

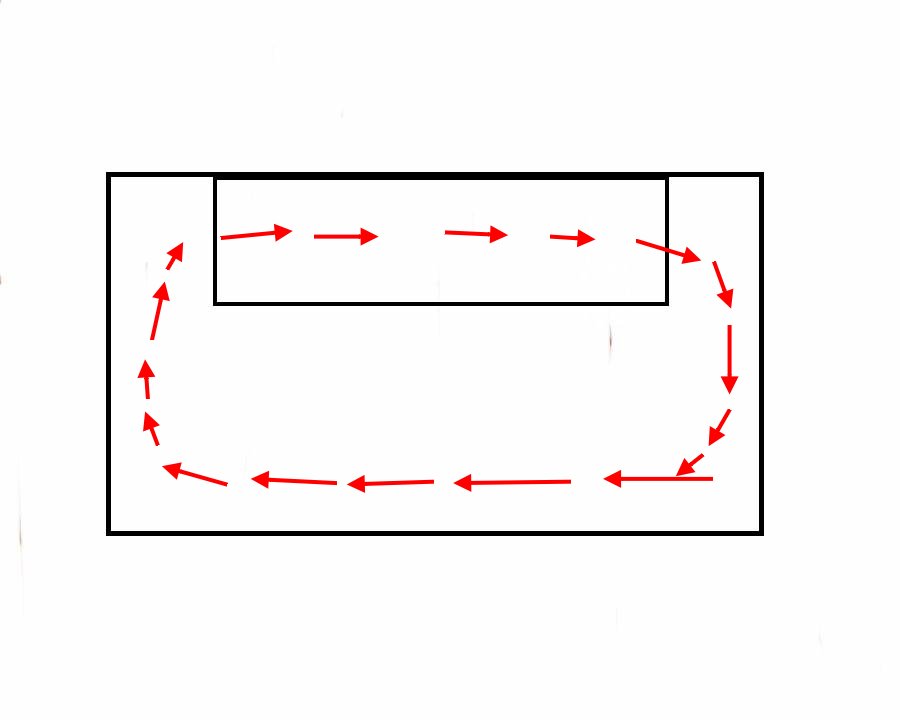

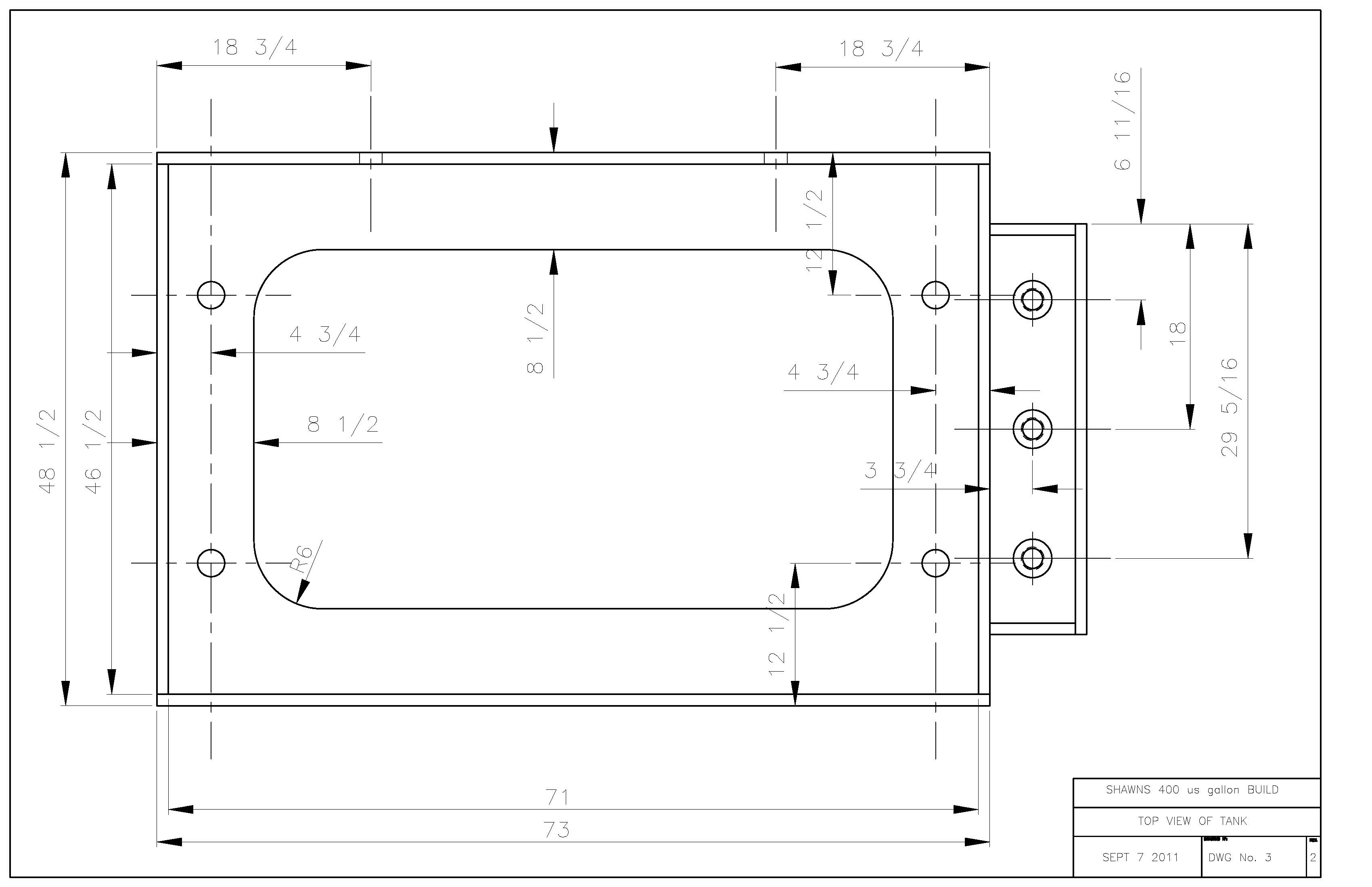

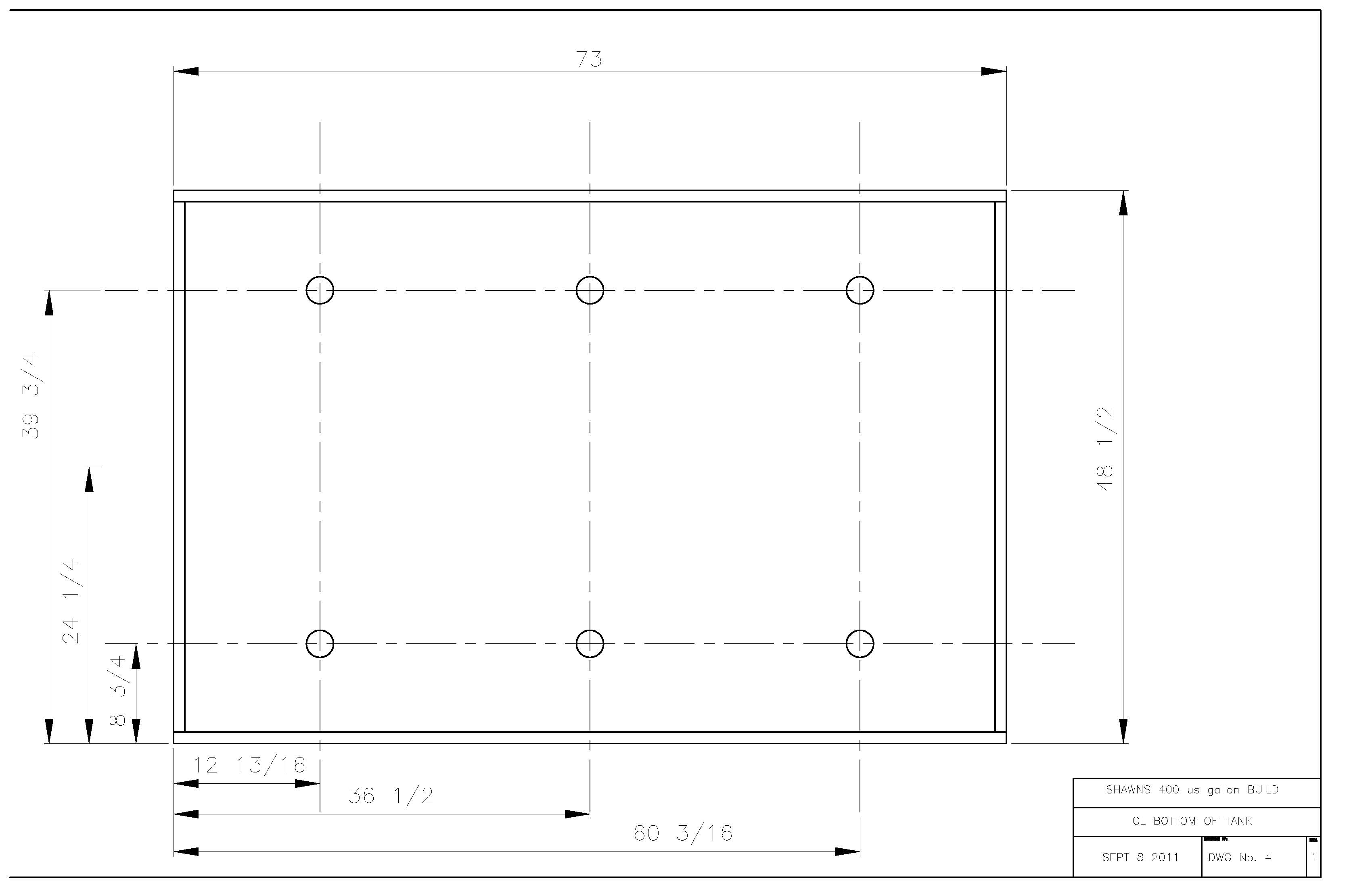

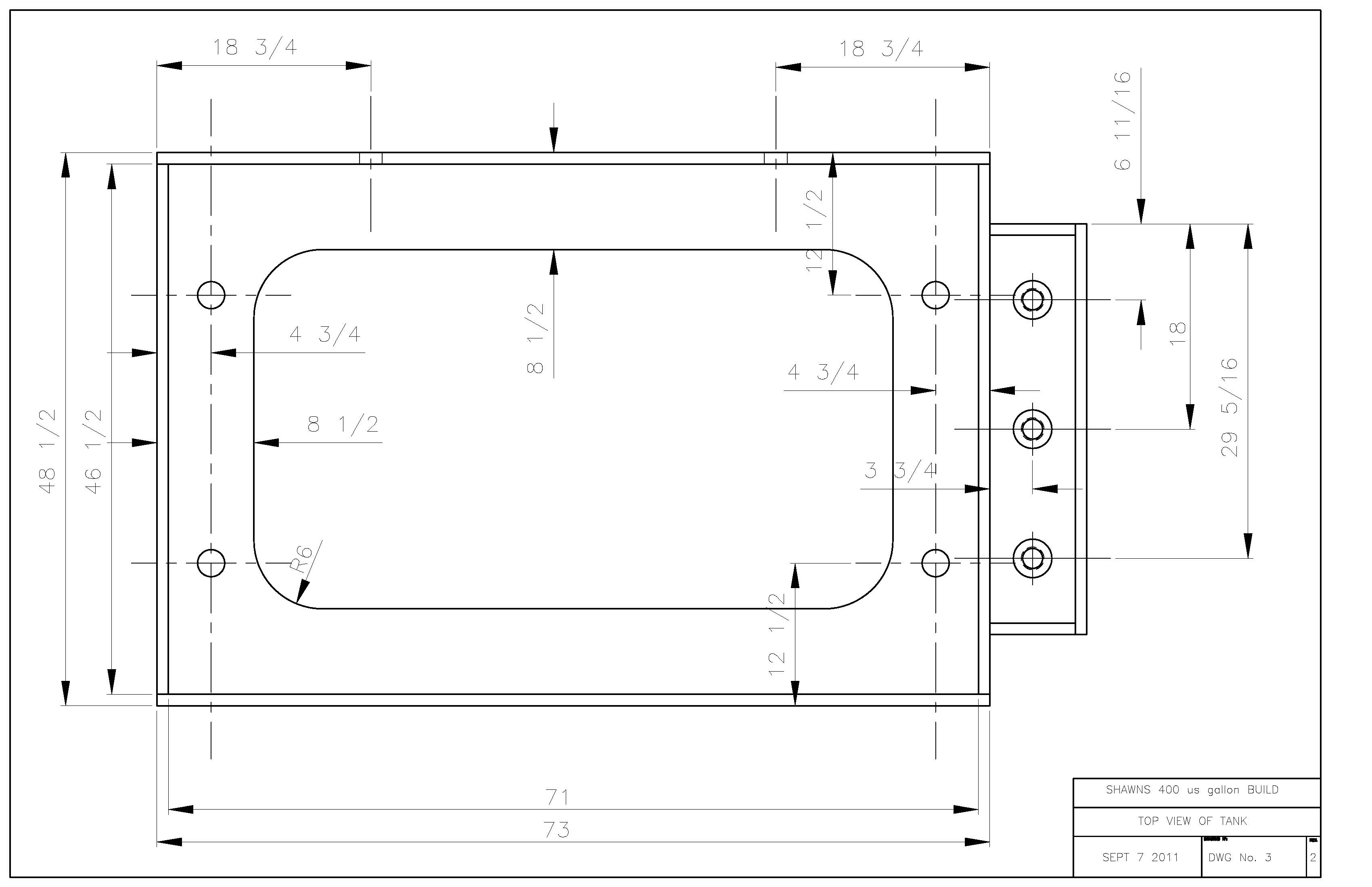

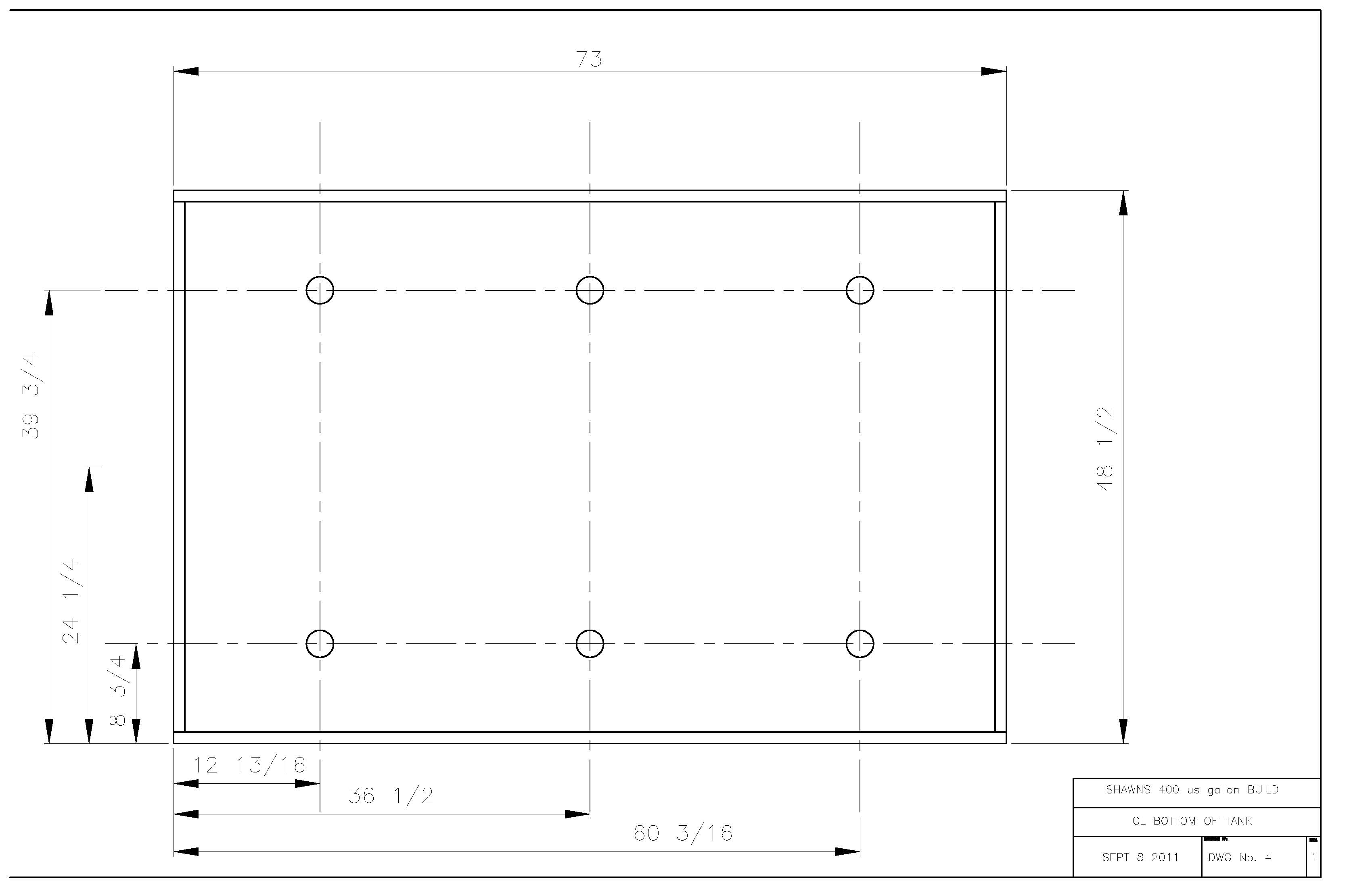

Trying hard not to make swiss cheese, but will be close. The 4 holes in the euro bracing. We had discussed returning water back to the tank....The 2 holes on the right side of the pic in the euro bracing looking at the pic over top of the overflow will be returns from the sump. I'm thinking they would be better served in that area as to keep the tank free of obtrusive objects.....These 2 holes would be returns from the sump and firing downward towards the bottom of the side panel attempting to push the water down and towards the left side of the tank......The bulkhead holes in the bottom of the tank will be 1 CL running an 8Way and will fire in order continuing the push of water to the far left end of the tank and attempting to direct it back up the left panel and there hopefully it will be pushed back across the tank by the use of the other 2 bulkheads on the left top euro bracing. These returns will push/fire back towards the overflow box.

I'm planning on using 1 1/2" bulkheads on the returns from the sump and those are rather big and beefy bulkheads to try to be drilling close to the top of the panel IMO. I think they'd sit rather low in the water line, and another issue IMO would be back siphon when power is shut off. I know there are ways to circumvent some, but I think it might be more than I like or want......

As I had mentioned to you earlier that is 1 of the 2 CL planned for the tank. The other CL bulkheads will probably be drilled in the side panels, but the left panel will create a bit of a challenge for me. I'm thinking I might build a VFD pump and use on these 4 bulkheads to have flow going in a circular motion length wise around the rock structure. I'm trying to figure a way as well, to be able to reverse that circular flow length wise around the rock flow with the use of another VFD pump. It would be easy to do with using a controller and shutting 1 pump down and starting the other, and at night time using a VFD pump you could really dial it down with the PLC to just have a gentle flow. Actually with the PLC you could alternate the on/off endlessly basically.....Again that is a project down the road. I need to ask lots of questions on the other forum about the prospects of it's use, but from what I've seen is very promising.

The biggest expense is the 3phase motors at roughly $200 a pop, and the wetends are roughly $120, and the AC Drives are roughly $100......Basically it would be cheaper to build than the OM......

3phase Baldor motor JM2450 $200.00

The FM50 AC Drive....$99.00

The only other component is the wet end from the Reeflo Barracuda pump for $119.00 from Reeflo directly.

The only thing that sucks is the pump has not mounts, so something has to be fabricated up to hold the pump securely.....

What are you thoughts so far on the plumbing?????

Trying hard not to make swiss cheese, but will be close. The 4 holes in the euro bracing. We had discussed returning water back to the tank....The 2 holes on the right side of the pic in the euro bracing looking at the pic over top of the overflow will be returns from the sump. I'm thinking they would be better served in that area as to keep the tank free of obtrusive objects.....These 2 holes would be returns from the sump and firing downward towards the bottom of the side panel attempting to push the water down and towards the left side of the tank......The bulkhead holes in the bottom of the tank will be 1 CL running an 8Way and will fire in order continuing the push of water to the far left end of the tank and attempting to direct it back up the left panel and there hopefully it will be pushed back across the tank by the use of the other 2 bulkheads on the left top euro bracing. These returns will push/fire back towards the overflow box.

I'm planning on using 1 1/2" bulkheads on the returns from the sump and those are rather big and beefy bulkheads to try to be drilling close to the top of the panel IMO. I think they'd sit rather low in the water line, and another issue IMO would be back siphon when power is shut off. I know there are ways to circumvent some, but I think it might be more than I like or want......

As I had mentioned to you earlier that is 1 of the 2 CL planned for the tank. The other CL bulkheads will probably be drilled in the side panels, but the left panel will create a bit of a challenge for me. I'm thinking I might build a VFD pump and use on these 4 bulkheads to have flow going in a circular motion length wise around the rock structure. I'm trying to figure a way as well, to be able to reverse that circular flow length wise around the rock flow with the use of another VFD pump. It would be easy to do with using a controller and shutting 1 pump down and starting the other, and at night time using a VFD pump you could really dial it down with the PLC to just have a gentle flow. Actually with the PLC you could alternate the on/off endlessly basically.....Again that is a project down the road. I need to ask lots of questions on the other forum about the prospects of it's use, but from what I've seen is very promising.

The biggest expense is the 3phase motors at roughly $200 a pop, and the wetends are roughly $120, and the AC Drives are roughly $100......Basically it would be cheaper to build than the OM......

3phase Baldor motor JM2450 $200.00

The FM50 AC Drive....$99.00

The only other component is the wet end from the Reeflo Barracuda pump for $119.00 from Reeflo directly.

The only thing that sucks is the pump has not mounts, so something has to be fabricated up to hold the pump securely.....

What are you thoughts so far on the plumbing?????

acrylic51

Active Member

Hope all is well my friend....My prayers are with you!!!!!! You've been more than helpful.

Not quite sure what you mean external to the overflow??? I guess the easiest way for me to explain is that the euro bracing will be done on the overflow box the same way it was done on the tank.....When the euro bracing is installed on the overflow box it will be even/level with the euro bracing of the tank. Where the tricky part comes into play is making a seamless joint between the tank euro bracing and the over flow euro bracing....I screwed up when having the sheet cut, and by the time I realized what I had told my buddies they were actually finishing up the cuts.....

Not a big deal just created a new venture for me.....

Not a big deal just created a new venture for me.....

Not quite sure what you mean external to the overflow??? I guess the easiest way for me to explain is that the euro bracing will be done on the overflow box the same way it was done on the tank.....When the euro bracing is installed on the overflow box it will be even/level with the euro bracing of the tank. Where the tricky part comes into play is making a seamless joint between the tank euro bracing and the over flow euro bracing....I screwed up when having the sheet cut, and by the time I realized what I had told my buddies they were actually finishing up the cuts.....

2quills

Well-Known Member

sounds like your getting closer to coming up with a final plan Shawn. Those vfd pumps look pretty sweet. I had been looking at one of the Tunze recirc pumps. For now they only have one pump with these capabilities, but it is able to be controlled using the tunze power head controlers. Unfortunately it's not a very powerfull pump. I had asked one of the tunze reps if there was other pumps like this in the works and he didn't say specifically yes but alluded to the idea that we should see some new designs before long.

acrylic51

Active Member

Quote:

Originally Posted by 2Quills http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414912

sounds like your getting closer to coming up with a final plan Shawn. Those vfd pumps look pretty sweet. I had been looking at one of the Tunze recirc pumps. For now they only have one pump with these capabilities, but it is able to be controlled using the tunze power head controlers. Unfortunately it's not a very powerfull pump. I had asked one of the tunze reps if there was other pumps like this in the works and he didn't say specifically yes but alluded to the idea that we should see some new designs before long.

Working on a finally plan......I'm trying to take what you and I had talked about as far as movement/flow within the tank, and also from what Paul had stated in his answer over on his forum about what I was after. I'm not sure it will give me 100% as how I have it depicted, but it should move water quite nicely from 1 side of the tank to the other. The big key IMO is to keep the detrious suspended in the water column so it has a chance to be picked up by the overflow.....

As far as the VFD, it doesn't appear to be a super hard swap of the motors and wetends. I think the real challenge is tuning the thing, and not blowing it apart, but the thread over on RC has taken some of the leg work out of starting points though on the setup.

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414900

The stiffeners are on the outside not covering the overflow just like the drawing 5" eurobracing.

The stiffener will be on the top, Haven't sat down yet and figured the radius or anything yet for the cutout on the euro bracing for the overflow.....The euro bracing won't be super wide. I want to leave as much working room inside the overflow as possible. Hopefully by the end of the night I'll at least have the template cut, so I can show you a test fit before it's glued into place.

Originally Posted by 2Quills http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414912

sounds like your getting closer to coming up with a final plan Shawn. Those vfd pumps look pretty sweet. I had been looking at one of the Tunze recirc pumps. For now they only have one pump with these capabilities, but it is able to be controlled using the tunze power head controlers. Unfortunately it's not a very powerfull pump. I had asked one of the tunze reps if there was other pumps like this in the works and he didn't say specifically yes but alluded to the idea that we should see some new designs before long.

Working on a finally plan......I'm trying to take what you and I had talked about as far as movement/flow within the tank, and also from what Paul had stated in his answer over on his forum about what I was after. I'm not sure it will give me 100% as how I have it depicted, but it should move water quite nicely from 1 side of the tank to the other. The big key IMO is to keep the detrious suspended in the water column so it has a chance to be picked up by the overflow.....

As far as the VFD, it doesn't appear to be a super hard swap of the motors and wetends. I think the real challenge is tuning the thing, and not blowing it apart, but the thread over on RC has taken some of the leg work out of starting points though on the setup.

Quote:

Originally Posted by Al&Burke http:///t/376802/415-gallon-plywood-tank-build/1120#post_3414900

The stiffeners are on the outside not covering the overflow just like the drawing 5" eurobracing.

The stiffener will be on the top, Haven't sat down yet and figured the radius or anything yet for the cutout on the euro bracing for the overflow.....The euro bracing won't be super wide. I want to leave as much working room inside the overflow as possible. Hopefully by the end of the night I'll at least have the template cut, so I can show you a test fit before it's glued into place.

acrylic51

Active Member

I did get a reply back from Paul and Cass over at OceansMotions late last night, and I had asked them if they could special build an 8Way OM with 1 1/2" ports, and they said due to the size of the unit itself and the 1 1/2" ports I was wanting it wasn't possible. Not a real big deal the 1" ports will work just fine.

What are your thoughts on the initial flow plan/pattern?

What are your thoughts on the initial flow plan/pattern?