leona

Member

Do having teeth on the side covers will that prevent any flow?

I guess I will figure that out about the teeth as soon as I can.

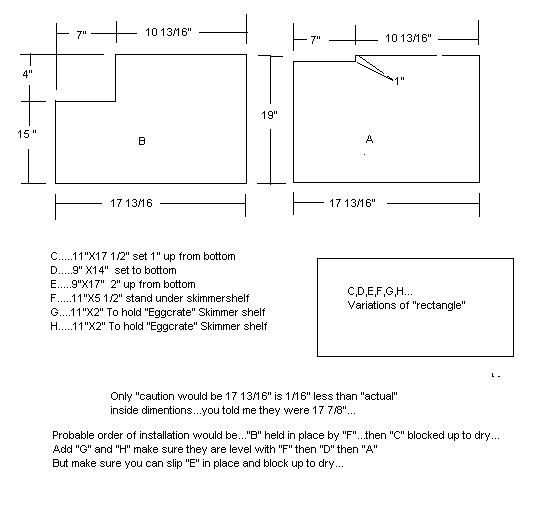

As for the baffles I only saw "A" but I will double check to see if I just missed them.

Well the big move is this weekend as far as getting the old tank moved to another room and build the stand, canopy,cabinets.

Should be fun. We will be picking up the tank on Next Friday.

I will keep everyone updated.

Leona

I guess I will figure that out about the teeth as soon as I can.

As for the baffles I only saw "A" but I will double check to see if I just missed them.

Well the big move is this weekend as far as getting the old tank moved to another room and build the stand, canopy,cabinets.

Should be fun. We will be picking up the tank on Next Friday.

I will keep everyone updated.

Leona